Electric field heavy metal leaching device and method

A heavy metal, electric field technology, applied in chemical instruments and methods, biological sludge treatment, water pollutants, etc., can solve the problems of slow restoration, long plant growth cycle, etc., to achieve voltage, wide application, leaching and dehydration uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The power supply method adopts continuous DC power supply, and the eluent is citric acid.

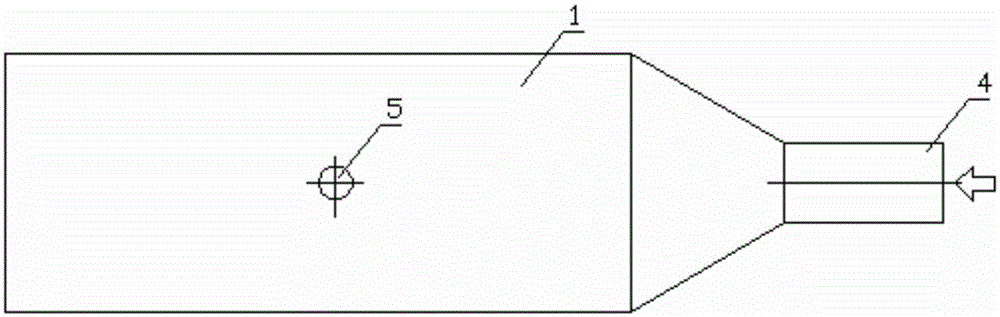

[0026] The anode plate 1 and the cathode plate 2 are connected to the positive pole and the negative pole of the DC power supply 3, the distance between the pole plates is 5mm, and the power supply voltage is 20V. Squeeze and inject the sludge 6 from the mud inlet 4, and at the same time release the eluent 7 to start rinsing. The concentration of citric acid is 0.6mol / L, and the flow rate is 0.1L / min. When the sludge 6 passes through the leaching dehydration electric field cavity, the heavy metals in it are fully dissolved under the action of acid production at the anode, strong oxidation, and acidification of the eluent, and are dehydrated with the water in the sludge 6 under the action of the electric field Liquid 9 flows out from the mesh cathode plate. The treated sludge 6 is discharged from the sludge outlet 8, and is collected uniformly for subsequent disposal. After tre...

Embodiment 2

[0030] The power supply mode is intermittent DC power supply, and the eluent is nitric acid.

[0031]The anode plate 1 and the cathode plate 2 are connected to the positive pole and the negative pole of the DC power supply 3, the distance between the pole plates is 20mm, and the power supply voltage is 80V. The specific operation of DC power supply intermittent power supply is: power supply for 1min, intermittent 20s, and so on cycle. Squeeze and inject the sludge 6 from the mud inlet 4, and at the same time release the eluent 7 to start rinsing. The concentration and flow rate of nitric acid are selected according to the demand, and the pH value of the sludge 6 is kept at about 2. When the sludge 6 passes through the leaching dehydration electric field cavity, the heavy metals in it are fully dissolved under the action of acid production at the anode, strong oxidation, and acidification of the eluent, and are released with the water in the sludge under the action of the elec...

Embodiment 3

[0035] The power supply mode is pulse power supply, and the eluent is hydrochloric acid + hydrogen peroxide.

[0036] The anode plate 1 and the cathode plate 2 are connected to the positive pole and the negative pole of the pulse power supply 3, the distance between the pole plates is 50mm, and the power supply voltage is 100V. Pulse power supply is automatically controlled, and the power supply time of each cycle accounts for 80%. Squeeze and inject the sludge 6 from the mud inlet 4, and at the same time release the eluent 7 to start rinsing. The eluent is a mixture of hydrochloric acid and hydrogen peroxide, and the oxidation of hydrogen peroxide can improve the effect of acid leaching. Hydrochloric acid and hydrogen peroxide are mixed and injected, the concentration of hydrogen peroxide is about 2%, and the pH value of sludge 6 is controlled at about 2 during operation. When the sludge 6 passes through the leaching dehydration electric field cavity, the heavy metals in it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com