Sewing product separation mechanism

A separation mechanism and a technology for sewing objects, applied in pile separation, object separation, thin material processing, etc., can solve the problems of unfavorable process automation development, unfavorable machine layering, low production efficiency, etc., to achieve automation development, smooth work, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

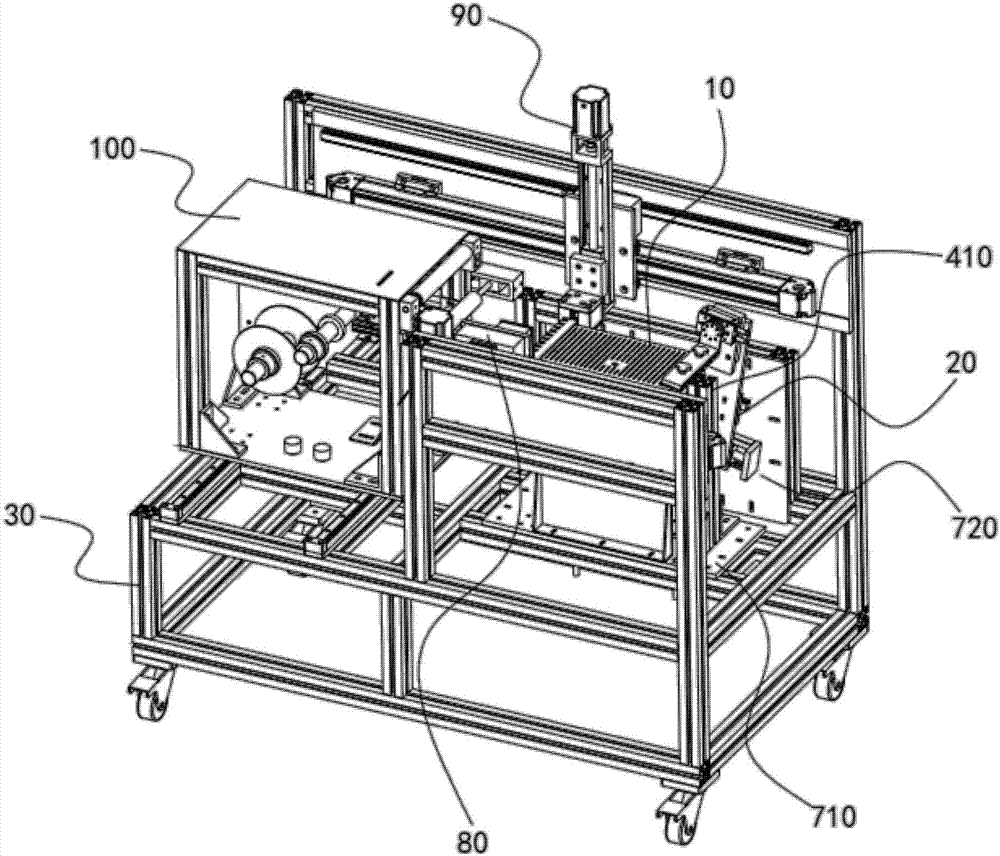

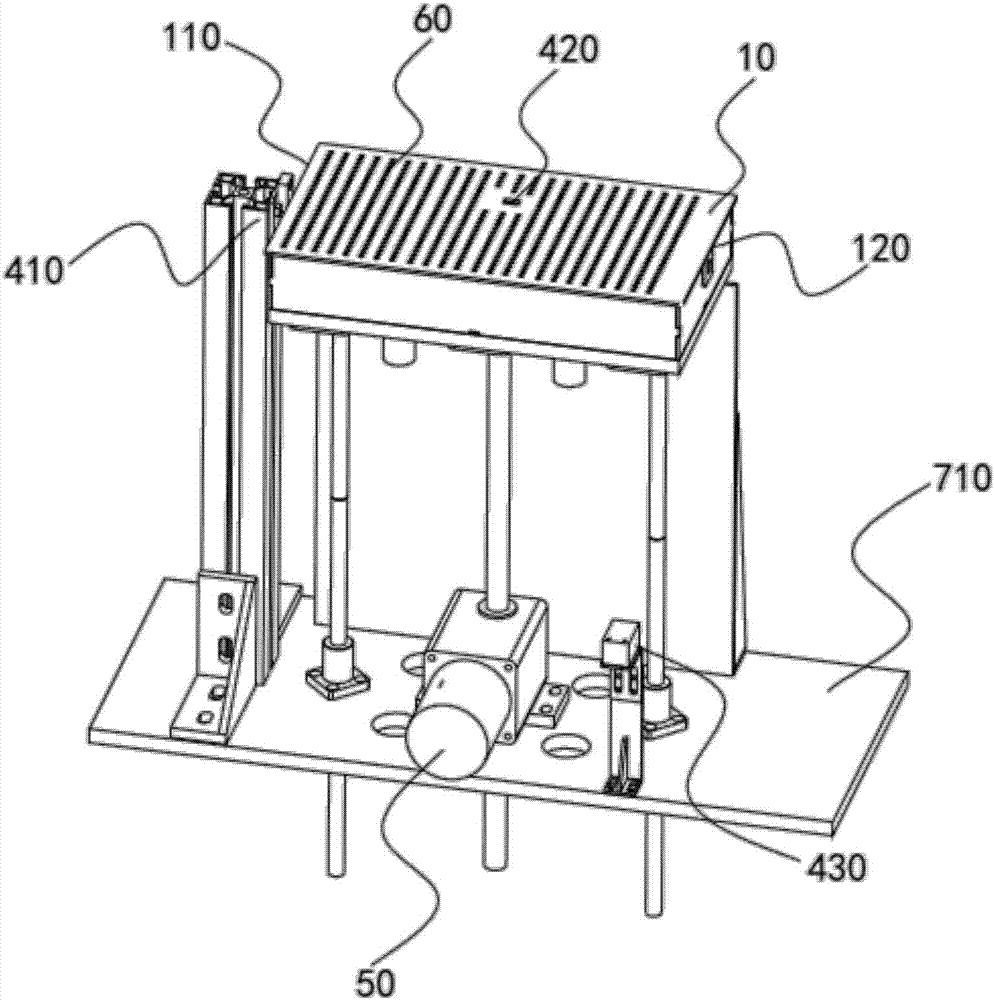

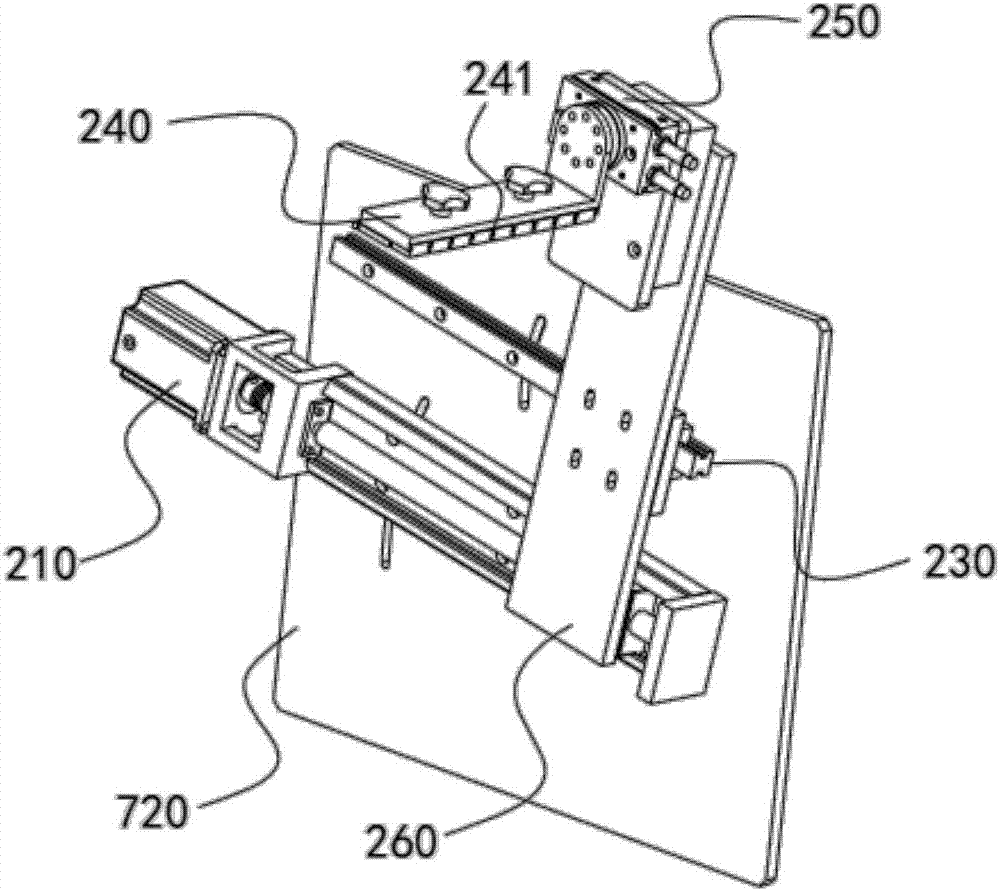

[0036] Such as Figure 1 to Figure 4As shown, a sewing object separation mechanism includes a feeding platform 10 and a hook device 20. The hook device 20 includes a first driving device 210 and at least one hook 220 located above the feeding platform 10. The hook 220 is provided for hooking the sewing The hook head 221 of the object, the discharge platform 10 is provided with the first working area 110 and the second working area 120 which are arranged oppositely, and the first driving device 210 drives the hook 220 to move between the first working area 110 and the second working area 120 .

[0037] The whole stack of sewing objects that have been cut is placed on the unwinding platform 10, the first driving device 210 drives the crochet needle 220 to move to the first working area 110 of the unloading platform 10, and after hooking the uppermost sewing obj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com