A wire cutting saw with variable arc length for processing hard and brittle materials

A wire cutting saw, hard and brittle material technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of low yield, limited cutting depth, inability to cut curves, etc., to achieve high material utilization, The effect of smooth cut surface and neat saw seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

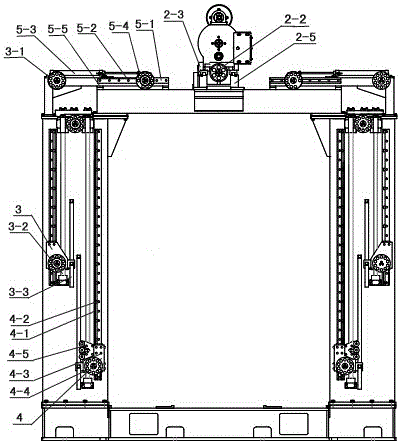

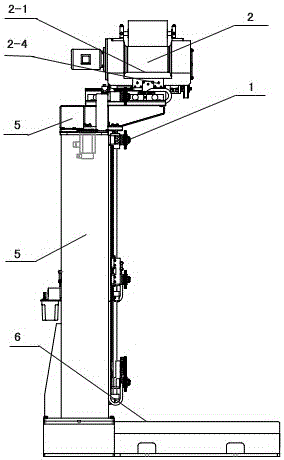

[0022] With reference to the attached drawings, a wire cutting saw with variable arc length for processing hard and brittle materials, including a wire guide wheel drive mechanism 1, a wire barrel and a wire transport mechanism 2, a wire tension adjustment and control mechanism 3, a drive cutting mechanism 4, a column and a beam 5. Workbench 6, where the workbench 6 is installed on the lower beam of the column and beam 5; the thread drum and the wire transport mechanism 2 are installed on the upper beam of the column and beam 5; the wire is installed on the column of the column and beam 5 Tension adjustment and control mechanism 3 and drive cutting mechanism 4; wire drum and wire transport mechanism 2 consists of wire storage drum 2-1, transmission mechanism 2-2, first guide rail 2-3, first screw 2-4, base 2 -5 composition, both ends of the wire storage barrel 2-1 are connected with the box body through bearings, the sliding seat on the box body and the first guide rail 2-3 fixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com