Disc Screen Feeder

A feeder and disc screen technology, applied in the direction of supply devices, manufacturing tools, etc., can solve the problems of increased resistance, increased wear of the extrusion arm, shortened service life of the extrusion arm, etc., to reduce wear and reduce operation Resistance, the effect of improving the mixing and homogenizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

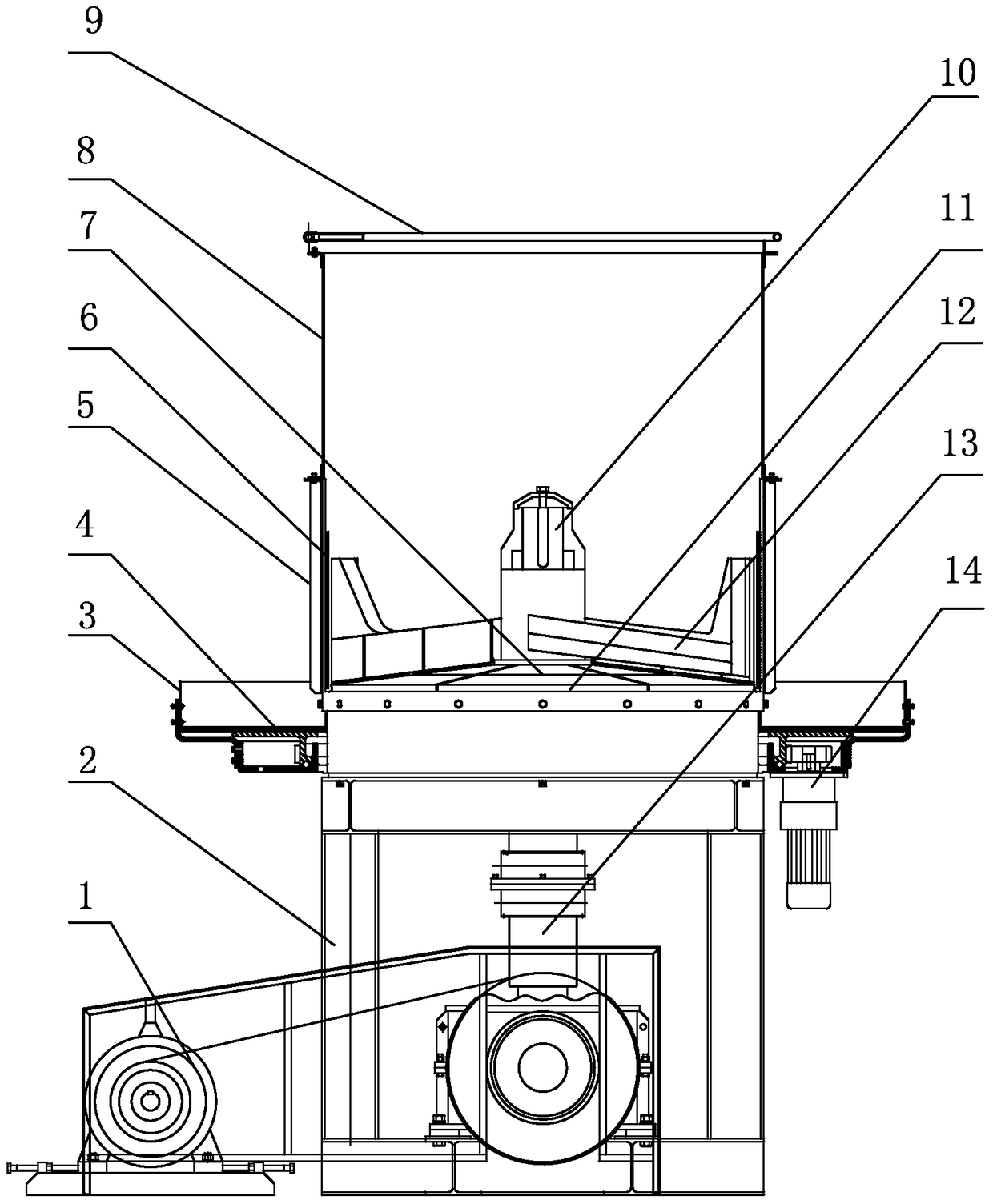

[0020] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

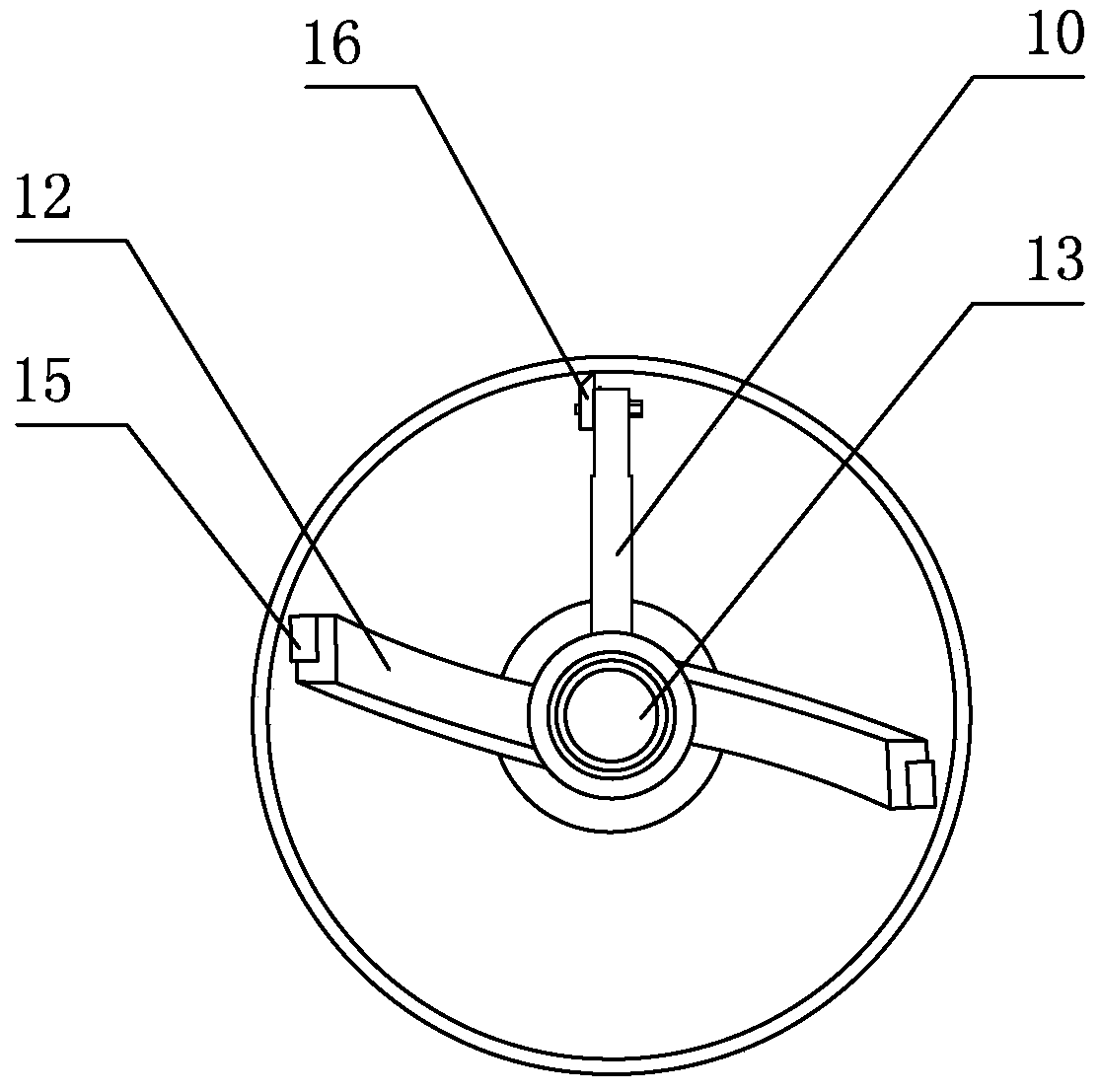

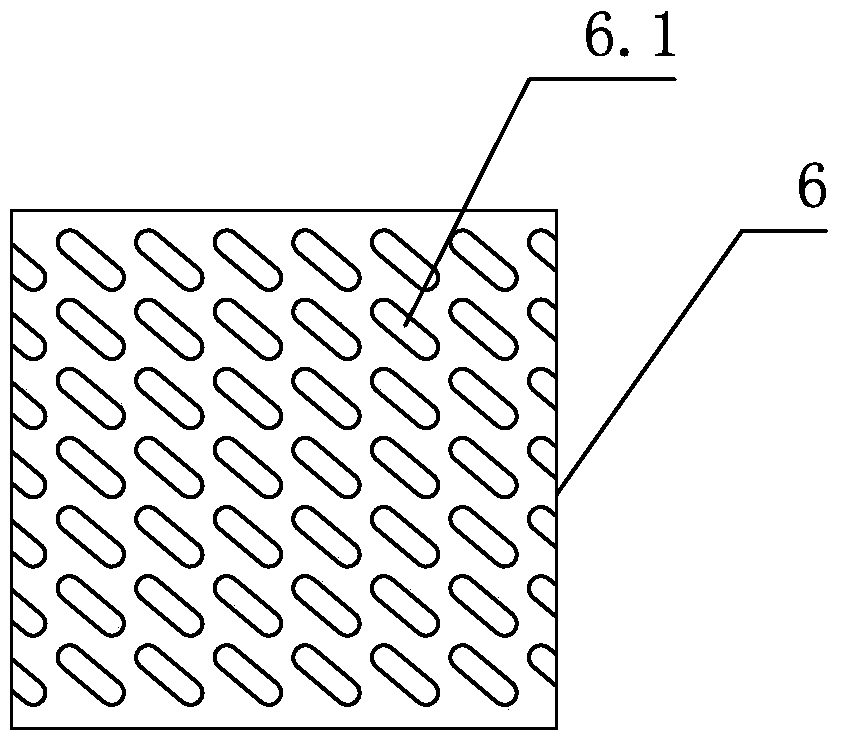

[0021] Such as Figure 1~3 As shown, the disc sieve feeder includes a frame 2, a main shaft 13 and a main transmission system 1 connected to the main shaft 13. The frame 2 is provided with a sieve drum, and the sieve drum is composed of a sieve plate 6 and a sieve drum bracket 5. , eight sieve plates 6 full of sieve holes 6.1 are evenly distributed along the circumference, and the sieve holes 6.1 on the sieve plate 6 are circular, polygonal or strip-shaped, preferably strip-shaped, and the strip shape consists of a rectangle and a rectangle It consists of two semicircles at both ends. Seven sieve plates 6 are directly fixed on the sieve cylinder support 5, and one sieve plate 6 is connected with the sieve cylinder support 5 through a joint door frame, which can facilitate the cleaning of the inside of the screen cylinder.

[0022] A chassis 11 is set a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com