Production method of bamboo mat

A production method and mat technology, applied in the field of bamboo mat production, can solve the problems of large bamboo chips, many processing steps, inconvenient storage, transportation and carrying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

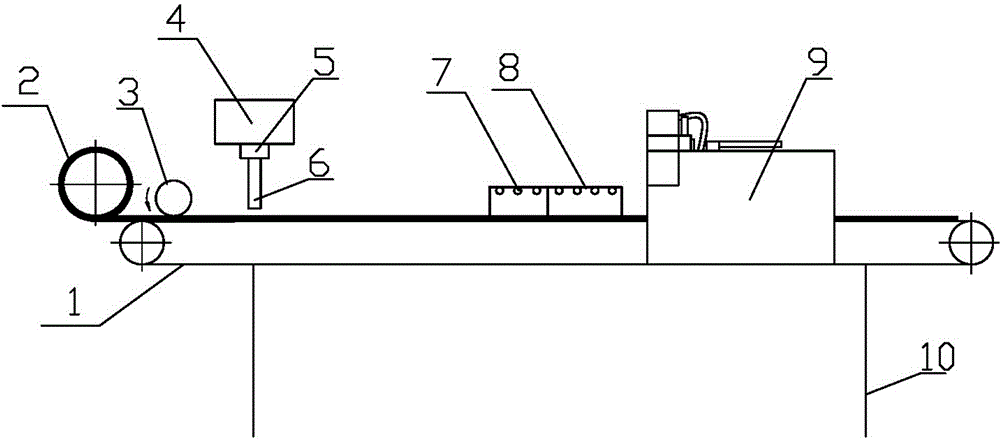

Method used

Image

Examples

Embodiment 2

[0059] A kind of bamboo summer mat production method, it comprises the following steps:

[0060] ⑴Bamboo slice processing: process bamboo into bamboo slices of required size;

[0061] In step (1) of the present invention, the shape of the bamboo slices is a mahjong block, that is, the size of the bamboo slices is (24㎜~26㎜)×(14㎜~16㎜)×(2.2㎜~2.6㎜) ).

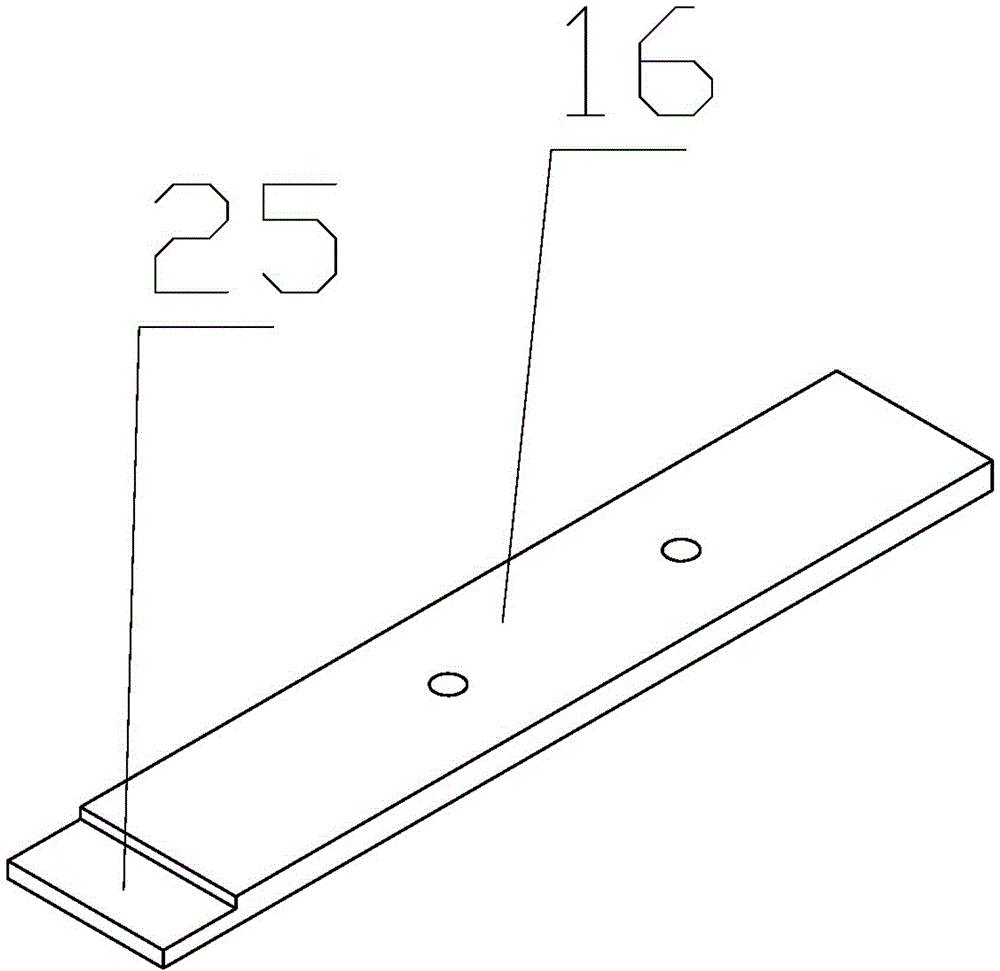

[0062] The size of the bamboo slice 24 in this embodiment is 24mm×14mm×2.5mm.

[0063] ⑵Prepare the base fabric: choose roll-shaped PVC foam anti-skid cloth as the base fabric, one side of which is flat and dense in texture;

[0064] The base fabric 2 of this embodiment is a pvc foamed environmental protection anti-bacteria anti-slip base fabric produced by Hebei Jiameile Plastic Products Co., Ltd., with a width of 195 cm.

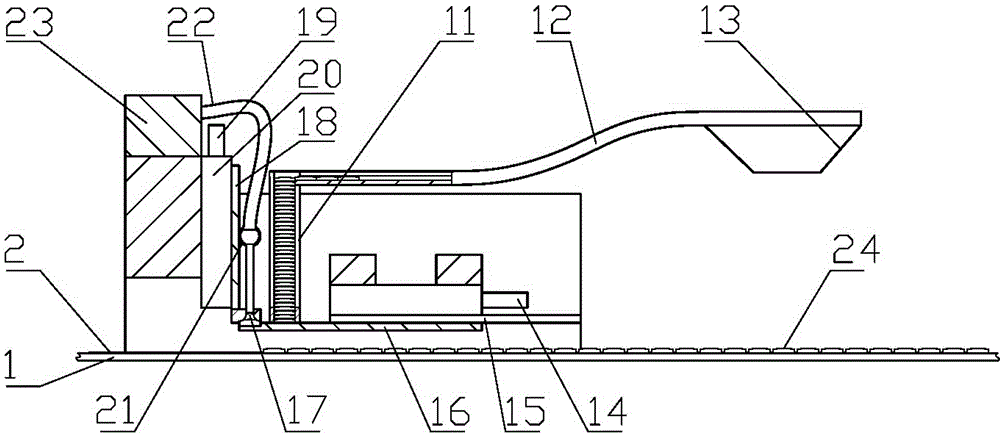

[0065] (3) Coating polyurethane glue: apply polyurethane glue on the flat surface of the base fabric through a glue applicator;

[0066] In step (3) of the present invention, the gluing mechanism includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com