Automatic shifting producing device for silent bearing retainer

A technology for silent bearings and production devices, which is applied in positioning devices, feeding devices, storage devices, etc., can solve the problems of silent bearing holder displacement, small metal discs, and easy displacement, so as to ensure accuracy , Reasonable structure design, avoid displacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

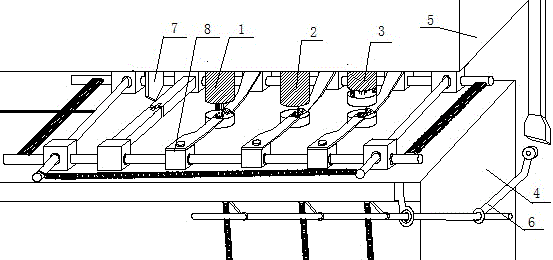

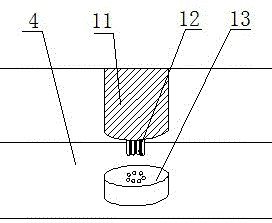

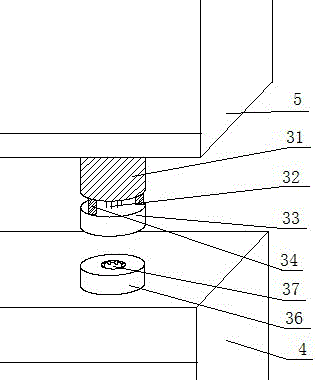

[0035] An automatic displacement production device for a silent bearing retainer, including a discharge assembly 7, a displacement assembly 8, a forming die 1, a shaping die 2 and a punching die 3, such as figure 1 ;

[0036] The discharge assembly 7 includes a discharge hydraulic cylinder, a retaining plate 72 and a vertebral plate 71, such as Figure 7 The discharging hydraulic cylinder is arranged on the machine tool, the retaining plate 72 is connected to the piston rod of the discharging hydraulic cylinder, the vertebral plate 71 is provided with a thread hole 73 for bolts to pass through, and the vertebral plate 71 is connected in the fixed position by bolts and nuts. On the plate 72, the left longitudinal guide block 89 is connected to the left block 816, the right longitudinal guide block 810 is connected to the right block 817, the ends of the left block 816 and the right block 817 are respectively provided with strip grooves, and the vertebral plate 71 is provided in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com