Component surface pollutant composite cleaning device and method

A technology for cleaning devices and parts, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., which can solve the problems of harmful personnel, large consumption of dry ice, high cost, etc., to avoid damage, avoid Effects that cause damage and reduce negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

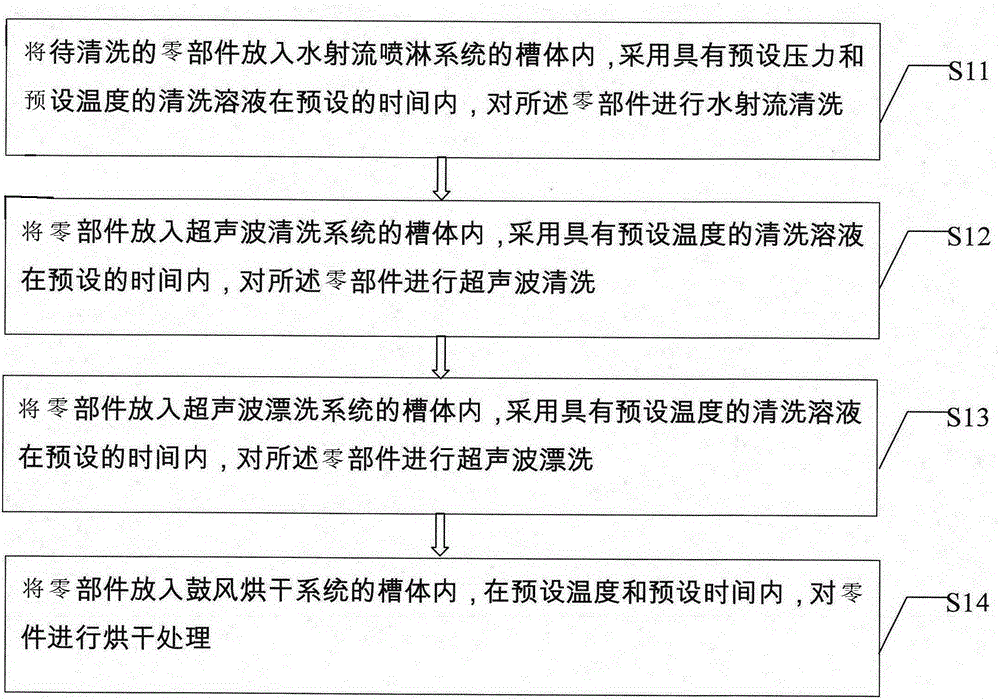

[0073] Please see Figure 4 , Figure 4 It is a flow chart of a specific embodiment of the compound cleaning method for surface pollutants of parts provided by the present invention.

[0074] The cleaning object in this embodiment is the heavy-duty Steyr diesel engine fuel injection pump parts with complex structure, various types and precision coordination, mainly including fuel injection pump casing, camshaft, plunger coupler, governor, etc. The inner and outer surfaces of these parts are attached to a large amount of heavy oil pollution, which is difficult to be effectively cleaned by conventional methods.

[0075] Step S11, put the parts to be cleaned into the tank of the water jet spraying system, and use a cleaning solution with a preset pressure and a preset temperature to clean the parts with water jets within a preset time.

[0076] (1) Liquid injection: Inject city water into the tank through the liquid inlet. The size of the tank is 1200mm×600mm×660mm. The volume ...

Embodiment 2

[0092] The cleaning object of this embodiment is the planetary reducer planetary frame of coal mining machinery equipment. Compared with the parts described in Embodiment 1, the surface grease and dirt of the planetary reducer planetary frame are relatively low, and the structure of the parts is relatively simple.

[0093] Step S21, put the parts to be cleaned into the tank of the water jet spraying system, and use a cleaning solution with a preset pressure and a preset temperature to clean the parts with water jets within a preset time.

[0094] (1) Liquid injection: Inject city water into the tank through the liquid inlet. The size of the tank is 1200mm×600mm×660mm. The volume of city water accounts for 90%-95% of the tank volume. Set the heating temperature at 50-55°C. Add 5 kilograms of sodium carbonate in the tank body, stir to make sodium carbonate dissolve completely.

[0095] (2) Loading: Put the hanging basket with the above parts to be cleaned through the conveying d...

Embodiment 3

[0110] The cleaning object in this embodiment is the concrete pump truck valve block with complex structure and serious surface oil pollution. Compared with the planet carrier of the planetary reducer described in Example 2, the grease and dirt on the surface of the valve block are also lower, but the structure of the parts is complex, with a large number of internal through holes and blind holes. In this embodiment, in view of the pollution state and structure of the inner and outer surfaces of the parts, the high-pressure and high-temperature water jet cleaning step is omitted, and ultrasonic precision cleaning and ultrasonic rinsing are directly performed.

[0111] Step S31, put the parts into the tank of the ultrasonic cleaning system, and use a cleaning solution with a preset temperature to perform ultrasonic cleaning on the parts within a preset time.

[0112] (1) Liquid injection: inject municipal water into the tank through the liquid inlet, the tank size is 1000mm×600...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com