Fishy smell removing freeze-dried instant rana japonica oil and preparation method thereof

A wood frog oil and deodorization technology, which is applied in the field of food processing, can solve the problems of nutrient loss, cumbersome, complicated procedures, etc., and achieve the effect of convenient consumption, strong applicability, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

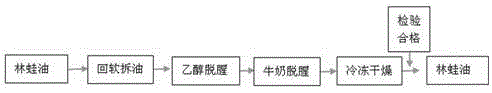

Method used

Image

Examples

Embodiment 1

[0028] A kind of preparation method of deodorization freeze-drying instant Rana oil, described preparation method comprises the following steps:

[0029] (a) First, spray alcohol evenly on the surface of multiple strands of wood frog lint oil, and refrigerate for 10~15 hours, then spread out the multiple strands of wood frog lint oil, and remove the fascia on the surface of the wood frog lint oil at the same time The impurity, obtains the wood frog oil of single strand;

[0030] (b) Soak the single-strand Rana oil obtained in step (a) in alcohol, carry out deodorization and adsorption for 20-40 minutes, take it out, and obtain the primary deodorization Rana oil after the alcohol volatilizes;

[0031] (c) Soak the primary deodorized Rana oil obtained in step (b) in milk, carry out further deodorization treatment for 3-10 minutes, take it out, and rinse off the milk remaining on the surface of Rana oil with running water to obtain secondary deodorized wood frog oil;

[0032] (...

Embodiment 2

[0046] This embodiment is a preferred scheme based on Embodiment 1. The preparation method of the deodorizing freeze-dried instant Rana oil of this embodiment is as follows:

[0047] (a) First, spray 50% alcohol evenly on the surface of multiple strands of wood frog lint oil, and place them in the refrigerator at 4°C for 12 hours, then spread out the multiple strands of wood frog lint oil and remove them at the same time Impurities including fascia on the surface of the wood frog thread oil, to obtain single-strand wood frog oil;

[0048] (b) Soak the single-strand wood frog oil obtained in step (a) in alcohol with a concentration of 95%, take it out after deodorization and adsorption for 30 minutes, and obtain the primary deodorization wood frog oil after the alcohol evaporates; among them, the use of alcohol The amount is 2ml / g wood frog oil;

[0049](c) Soak the primary deodorized Rana oil obtained in step (b) in milk, carry out further deodorization treatment for 5 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Expansion | aaaaa | aaaaa |

| Expansion | aaaaa | aaaaa |

| Expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com