Formula and method for improving gas producing and holding capacity of raw frozen steamed bread

A technology of capacity and steamed bread, which is applied in the field of improving the gas production and gas holding capacity of frozen raw steamed bread, can solve the problems of gas production and gas holding capacity decline, gas production capacity reduction, weakened gluten, etc., and achieve the enhancement of gas production and gas holding capacity , Improve the effect of gas production capacity and gas production increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

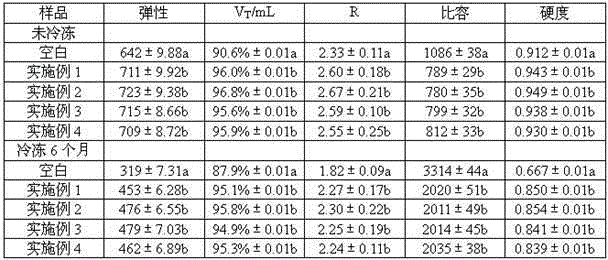

Examples

Embodiment 1

[0015] The present invention mixes 6‰ yeast and 8‰ compound additives into the flour according to the weight ratio of the flour, adds 50% of the weight of the flour and water, beats it in a dough mixer at a medium speed until the dough is fully expanded, stands still and shaped, and after -34 After quick-freezing at -18°C for 6 months, thaw at 37°C and 75% relative humidity to make steamed buns. Wherein its component proportion of compound additive is calculated by weight:

[0016] Sodium bicarbonate 11, calcium carbonate 3, sodium pyrophosphate 17, ascorbic acid 6, calcium stearoyl lactylate 35, diacetyl tartrate monoglyceride 17, sodium alginate 11.

Embodiment 2

[0018] The present invention mixes 6‰ yeast and 8‰ compound additives into the flour according to the weight ratio of the flour, adds 50% of the weight of the flour and water, beats it in a dough mixer at a medium speed until the dough is fully expanded, stands still and shaped, and after -34 After quick-freezing at -18°C for 6 months, thaw at 37°C and 75% relative humidity to make steamed buns. Wherein its component proportion of compound additive is calculated by weight:

[0019] Sodium bicarbonate 12, calcium carbonate 3, sodium pyrophosphate 16, ascorbic acid 6, calcium stearoyl lactylate 34, diacetyl tartrate monoglyceride 16, sodium alginate 13.

Embodiment 3

[0021] The present invention mixes 6‰ yeast and 8‰ compound additives into the flour according to the weight ratio of the flour, adds 50% of the weight of the flour and water, beats it in a dough mixer at a medium speed until the dough is fully expanded, stands still and shaped, and after -34 After quick-freezing at -18°C for 6 months, thaw at 37°C and 75% relative humidity to make steamed buns. Wherein its component proportion of compound additive is calculated by weight:

[0022] Sodium bicarbonate 12, calcium carbonate 2, sodium pyrophosphate 19, ascorbic acid 4, calcium stearoyl lactylate 37, diacetyl tartrate monoglyceride 14, sodium alginate 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com