Combined deep loosen cultivator

A cultivator and subsoiling technology, which is applied to agricultural machinery and tools, shovels, plows, etc., can solve the problems of reducing operation speed, increasing production and processing costs, and secondary inconvenience, so as to improve work efficiency, save machine tool costs, and Labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

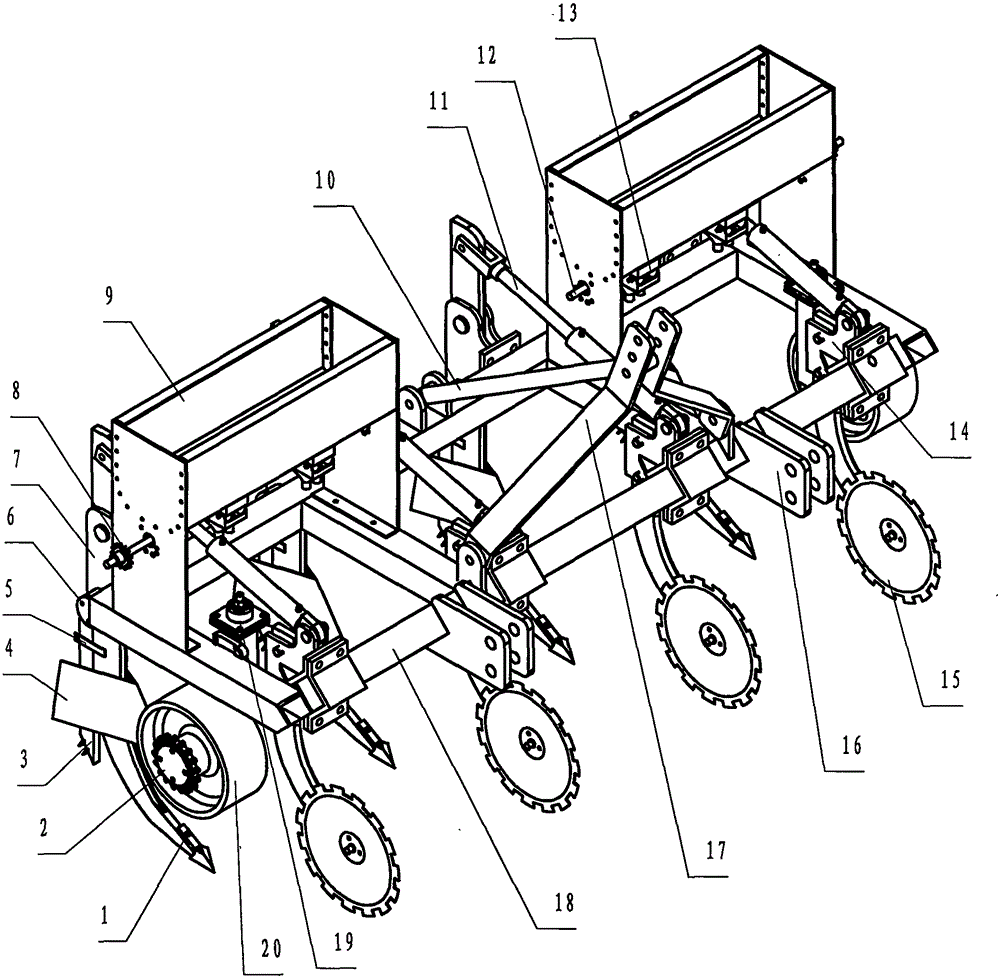

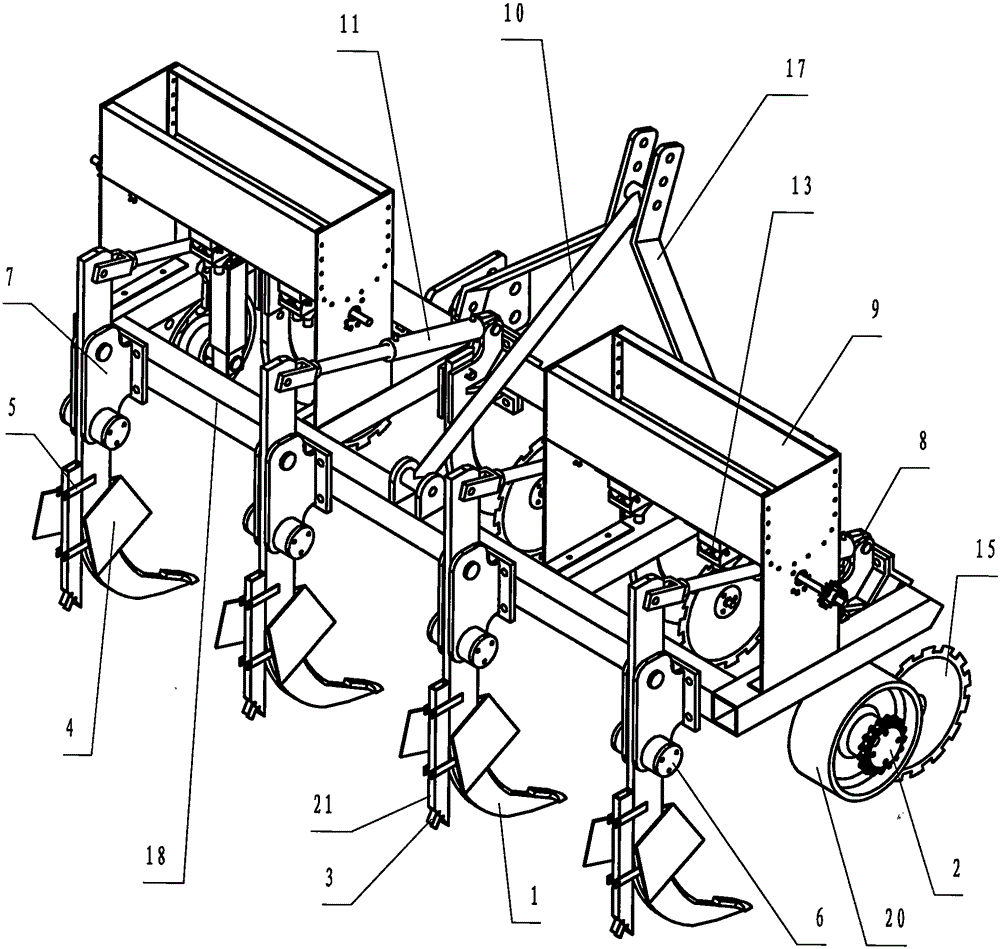

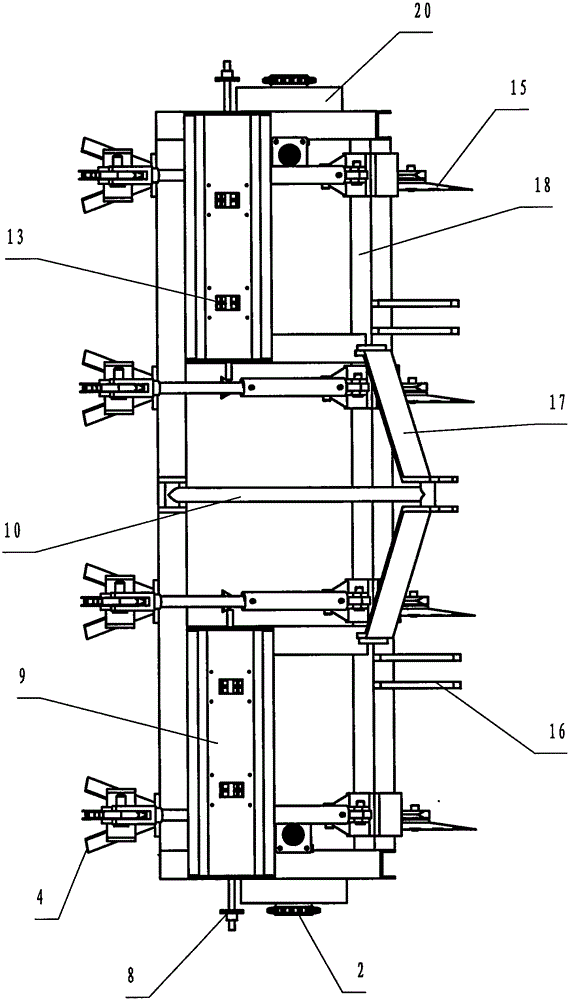

[0024] Embodiment: refer to attached Figure 1~5, the present invention comprises frame 18, and described frame 18 is provided with traction device, fertilization device, subsoiling device, depth-limiting device and cultivating device; Described traction device is located at frame 18 front upper parts, and traction device consists Upper traction plate 17, following traction plate 16 and traction inclined rod 10 constitute; Described fertilization device is the layered fertilization device that can fertilize layer by layer, and described layered fertilization device consists of fertilization box 9, driven shaft 12, from Moving sprocket 8, fertilizer box funnel 13, adjusting bolt 22, layered adjustment plate 3 and layered fertilization pipe 21 constitute; described fertilization box 9 is arranged on frame 18 top, and fertilizer box funnel 13 is located at the bottom of fertilizer box 9 , the layered fertilization pipe 21 is located at the bottom of the fertilization box 9 and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com