A high-stability force generator with compensation

A force generator, high stability technology, applied in the field of high stability force generator, can solve the problem of unstable force output capability of force generator, unstable force output capability of generator, large constant force or moment of force generator and other problems, to achieve the effect of improving radial uniformity, improving coaxiality, and reducing constant force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The high-stability force generator with compensation according to the present invention will be further described in detail with reference to the accompanying drawings and specific implementation.

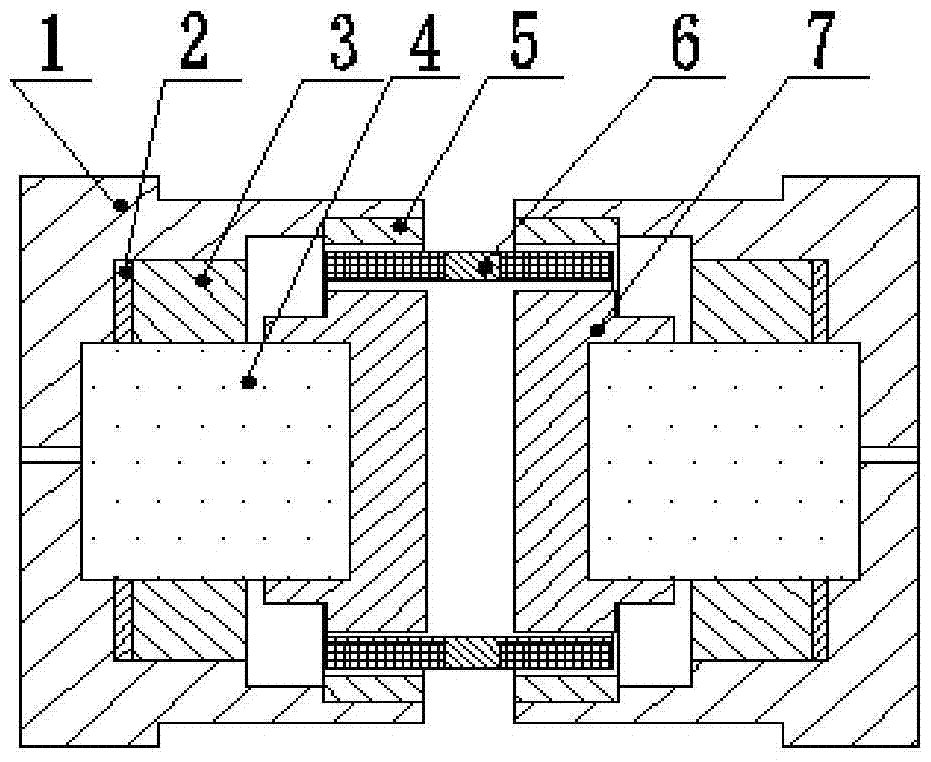

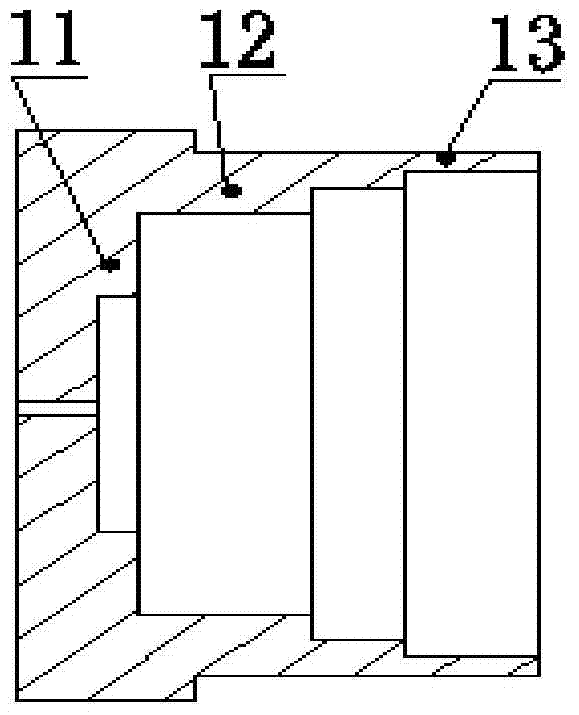

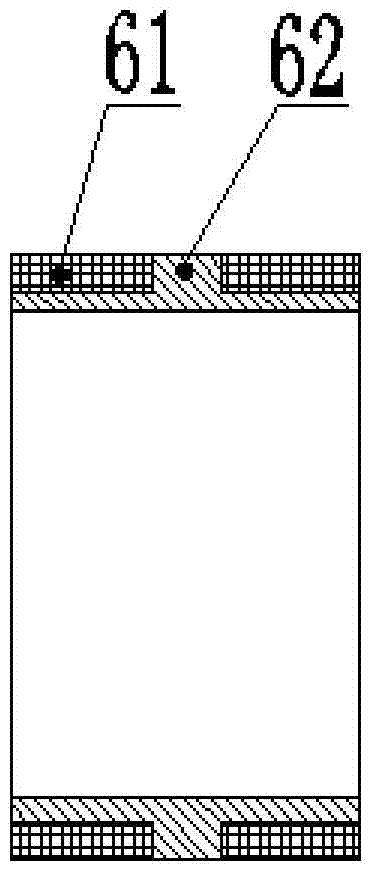

[0026] like Figure 1-Figure 3 As shown, the high stability force generator with compensation of the present invention includes a housing 1 , a compensation plate 2 , a positioning ring 3 , a magnetic steel 4 , a magnetic conducting ring 5 , a moving frame 6 , and a magnetizing ring 7 . in. The casing 1 has a hollow cavity structure of revolution, including a first cylinder 11, a second cylinder 12, and a third cylinder 13 that are sequentially connected and the inner cavities are connected to each other. The first cylinder 11, the second cylinder 12, The inner diameter of the third cylinder 13 gradually increases, and one end of each cylinder is provided with an outwardly protruding boss, so as to facilitate the axial positioning of each component in the inner cavity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com