Separation membrane and preparation method thereof, and lithium ion battery using the separation membrane

A separator and polymer technology, applied in the field of separators with good cycle and safety performance and their preparation, can solve the problem of difficulty in ensuring long-term coating thickness uniformity, affecting battery cycle and rate performance, slitting knives and coating rollers problems such as large loss, to achieve the effect of improving the rate and cycle performance, easy to realize industrial production, and reducing the cost of slurry and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

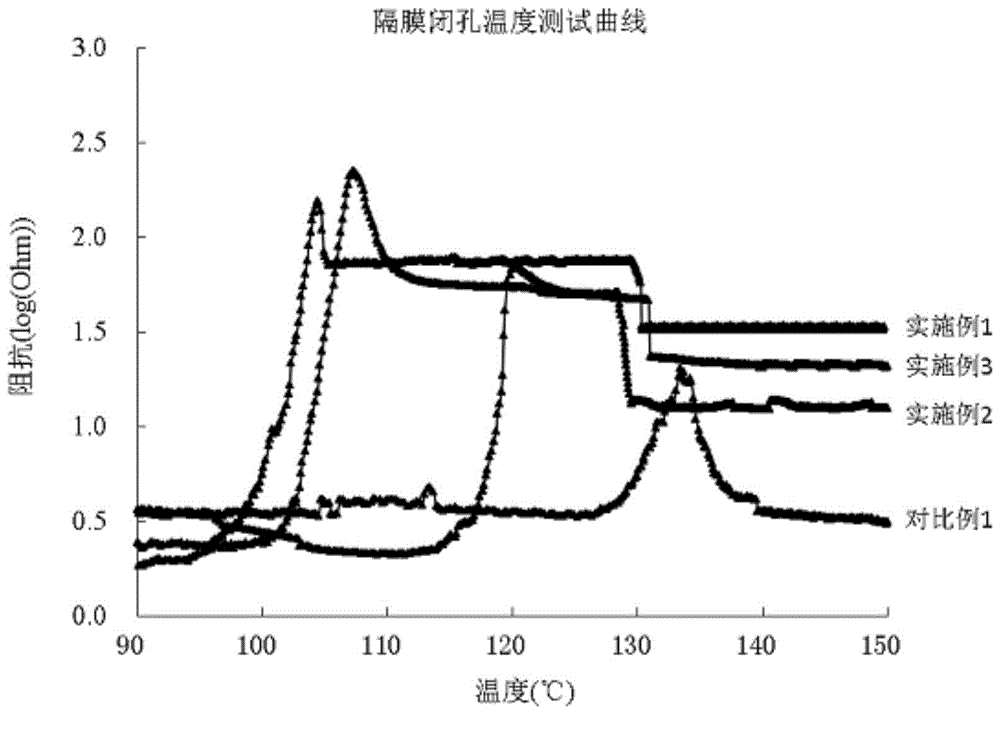

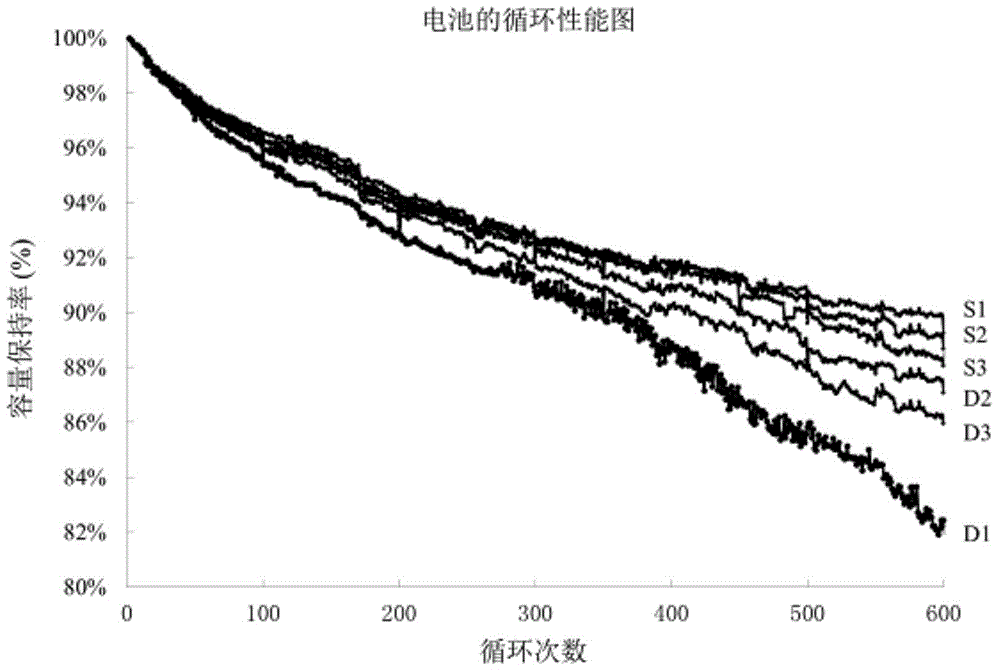

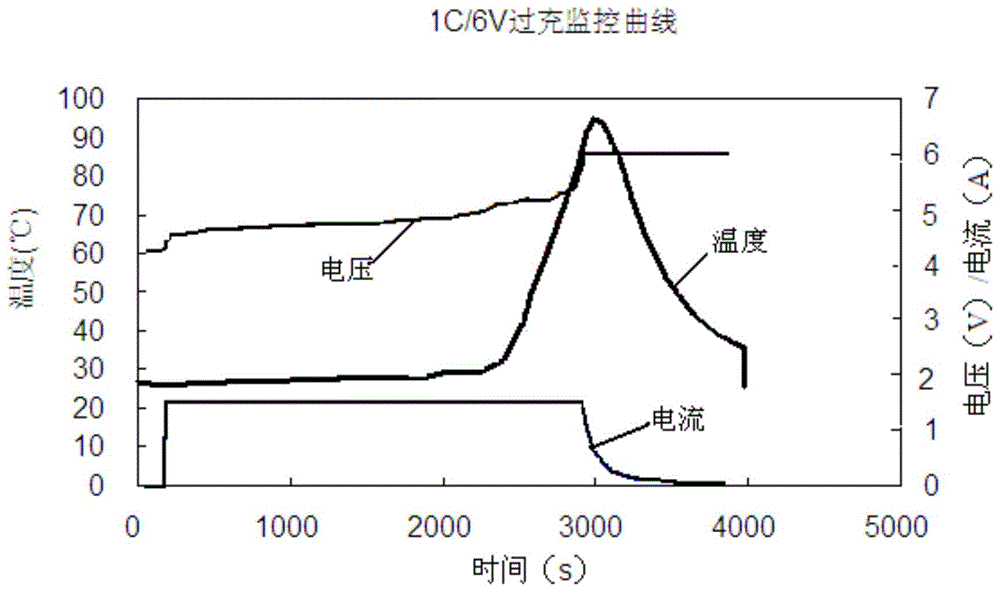

Embodiment 1

[0036] The preparation steps of the diaphragm of this embodiment are:

[0037]1) Add ultra-fine glass fibers with an average diameter of 1000nm to a polyethylene wax emulsion with a solid content of 25% in a mass ratio of 1:10 (the average particle size of polyethylene wax is 0.5 μm, the melting point is 105 ° C, the molecular weight 5000, the solvent is deionized water), stirred and immersed for 60 minutes, filtered and dried to obtain ultra-fine glass fibers with a polyethylene wax coating thickness of 2 μm;

[0038] 2) Add water and water-soluble sodium carboxymethylcellulose into the stirring grinder at a mass ratio of 98.5:1.5 to completely dissolve the sodium carboxymethylcellulose to obtain an aqueous solution of sodium carboxymethylcellulose;

[0039] 3) Add the ultra-fine glass fiber coated with polyethylene wax into the sodium carboxymethyl cellulose aqueous solution in proportion, and obtain the primary slurry after stirring;

[0040] 4) Add styrene-acrylic latex t...

Embodiment 2

[0044] The preparation steps of the diaphragm of this embodiment are:

[0045] 1) Add ultra-fine glass fibers with an average diameter of 500nm to polyethylene wax emulsion with a solid content of 30% in a mass ratio of 1:20 (the average particle size of polyethylene wax is 0.5μm, the melting point is 110°C, and the molecular weight 8000, the solvent is deionized water), stirred and soaked for 60 minutes, filtered and dried to obtain ultrafine glass fibers with a polyethylene wax coating thickness of 1 μm;

[0046] 2) Add water and water-soluble carboxyethyl cellulose to the stirring grinder at a mass ratio of 98.5:1.5 to completely dissolve the sodium carboxymethyl cellulose to obtain an aqueous solution of sodium carboxymethyl cellulose;

[0047] 3) Add the ultra-fine glass fiber coated with polyethylene wax into the sodium carboxymethyl cellulose aqueous solution in proportion, and obtain the primary slurry after stirring;

[0048] 4) Add styrene-acrylic latex to the prima...

Embodiment 3

[0052] The preparation steps of the diaphragm of this embodiment are:

[0053] 1) Add ultra-fine glass fibers with an average diameter of 500nm to a polypropylene wax emulsion with a solid content of 25% in a mass ratio of 1:20 (the average particle size of polypropylene wax is 1 μm, the melting point is 120°C, and the molecular weight is 8000, the solvent is deionized water), stirred and soaked for 60 minutes, filtered and dried to obtain ultra-fine glass fibers with a polypropylene wax coating thickness of 1 μm;

[0054] 2) Add water and water-soluble sodium carboxymethylcellulose into the stirring grinder at a mass ratio of 98.5:1.5 to completely dissolve the sodium carboxymethylcellulose to obtain an aqueous solution of sodium carboxymethylcellulose;

[0055] 3) Add the ultra-fine glass fiber coated with polypropylene wax into the sodium carboxymethyl cellulose aqueous solution in proportion, and obtain the primary slurry after stirring;

[0056] 4) Add styrene-acrylic la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com