Internal-pressure-cylinder pressure testing method and system

A pressure test, cylinder technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of high liquid temperature requirements, high vaporization pressure, low viscosity, etc., to simplify the test. System, fast pressure relief, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

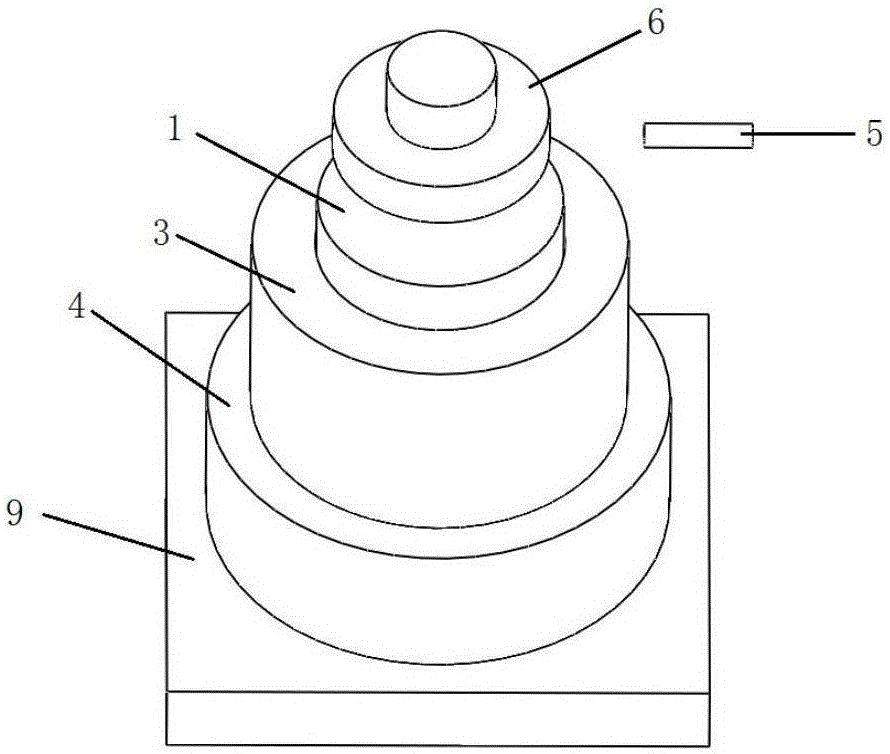

[0018] as attached figure 1 and 2 As shown, the present invention provides an internal pressure cylinder pressure test system, comprising a press 6, an upper pressure plate 1, a compression body 2, a lower pressure plate 7, a test cylinder 3, a base 4, a pressure sensor 8, a deformation measurement Component 5 and Workbench 9;

[0019] The compression body 2 is made of solid elastic material and has a cylindrical shape;

[0020] The upper surface of the base 4 is processed with two-stage stepped holes, the lower surface is processed with a cylindrical boss, and the stepped hole is coaxial with the central axis of the cylindrical boss;

[0021] A central positioning groove is processed on the upper surface of the workbench 9;

[0022] The cylindrical boss of the base 4 is fixedly connected with the central positioning groove of the workbench 9, the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com