Gas pouring apparatus based on container sealing test

A container sealing and gas device technology, which is applied to the device of gas mutual deflation in the pressure vessel. The field of gas deflation device based on the container sealing test can solve the problems of energy waste, achieve the effect of ensuring accuracy and reducing filling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

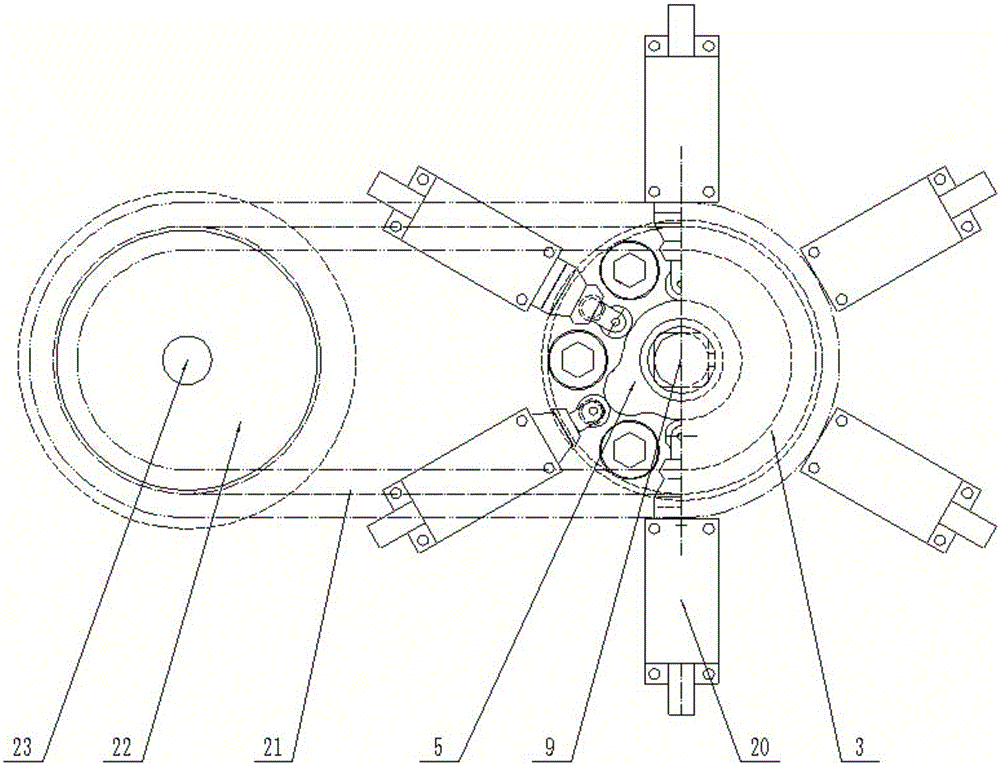

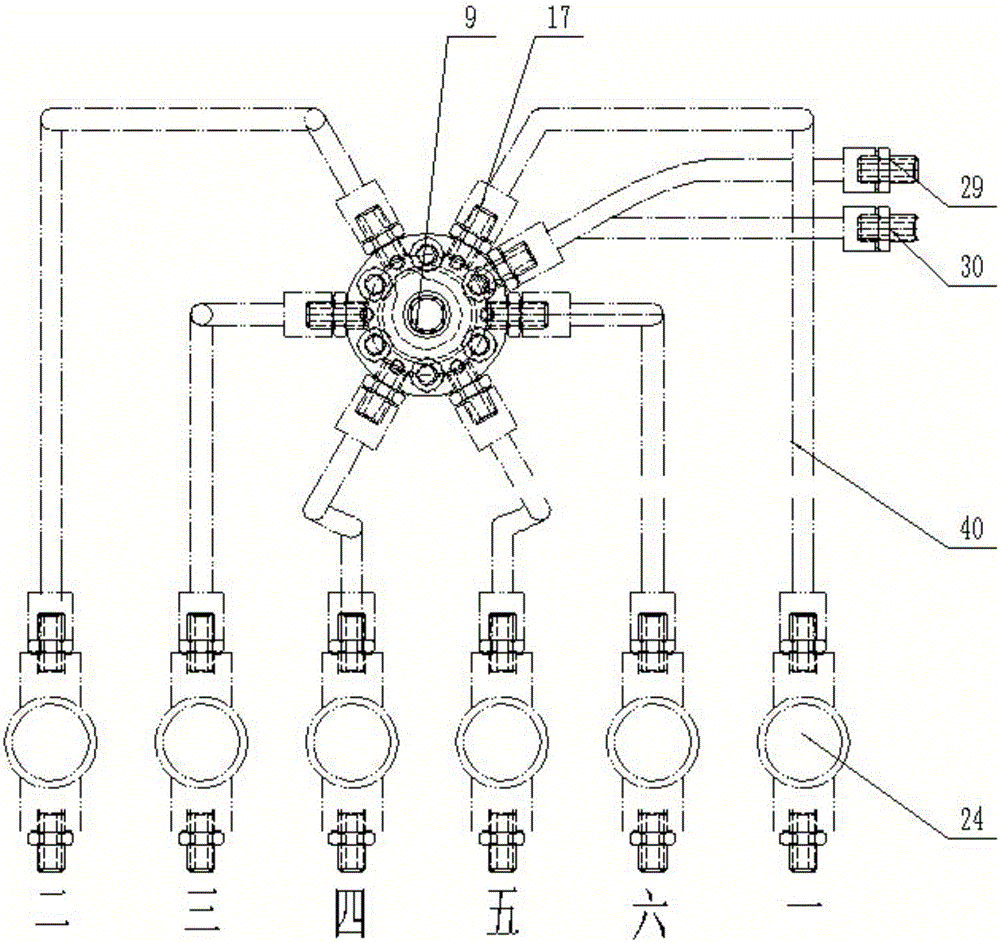

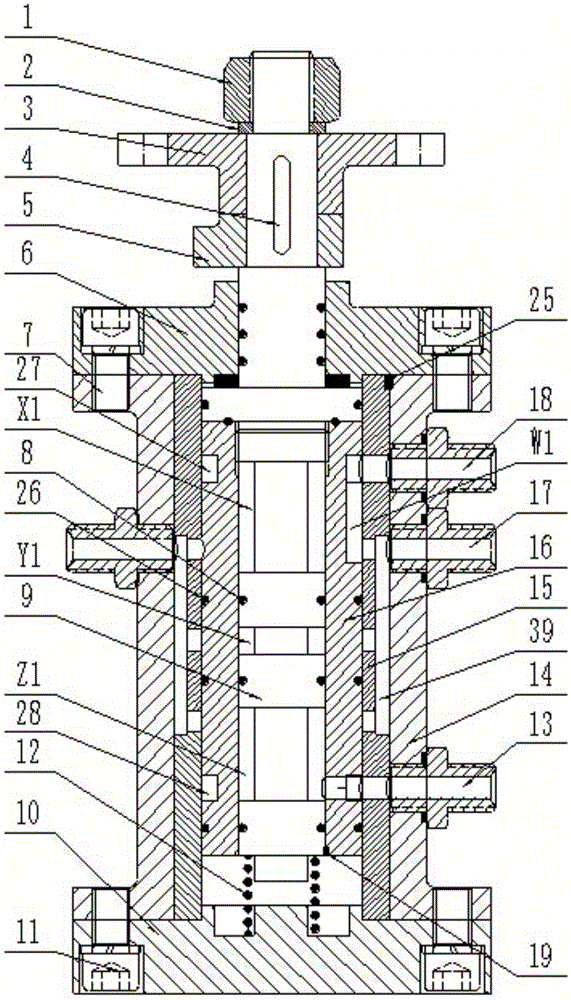

[0025] A deflation device based on a container sealing test, including a power assembly, a pipeline assembly, and a distributor assembly; the power assembly includes a stepper motor 23, a drive sprocket 22, and a transmission chain 21 installed in accordance with a working relationship And limit switch 20; Described pipeline assembly comprises intake pipe 29, exhaust pipe 30 and six air distribution pipes 40, is provided with the electromagnetic valve 24 controlled by limit switch 20 on air distribution pipe 40; The distributor The assembly includes a distributor shaft 9, a lower cover plate 10 is provided at the bottom of the distributor shaft 9 through a spring 12 and a bolt B 11, and an inner sleeve 16, a middle s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com