Sealed incinerator

An incinerator, sealed technology, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as high temperature gold and toxic gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following, numerous specific details are set forth in order to provide a thorough understanding of the concepts underlying the described embodiments. It will be apparent, however, to one skilled in the art that the described embodiments may be practiced without some or all of these specific details. In other instances, well known processing steps have not been described in detail.

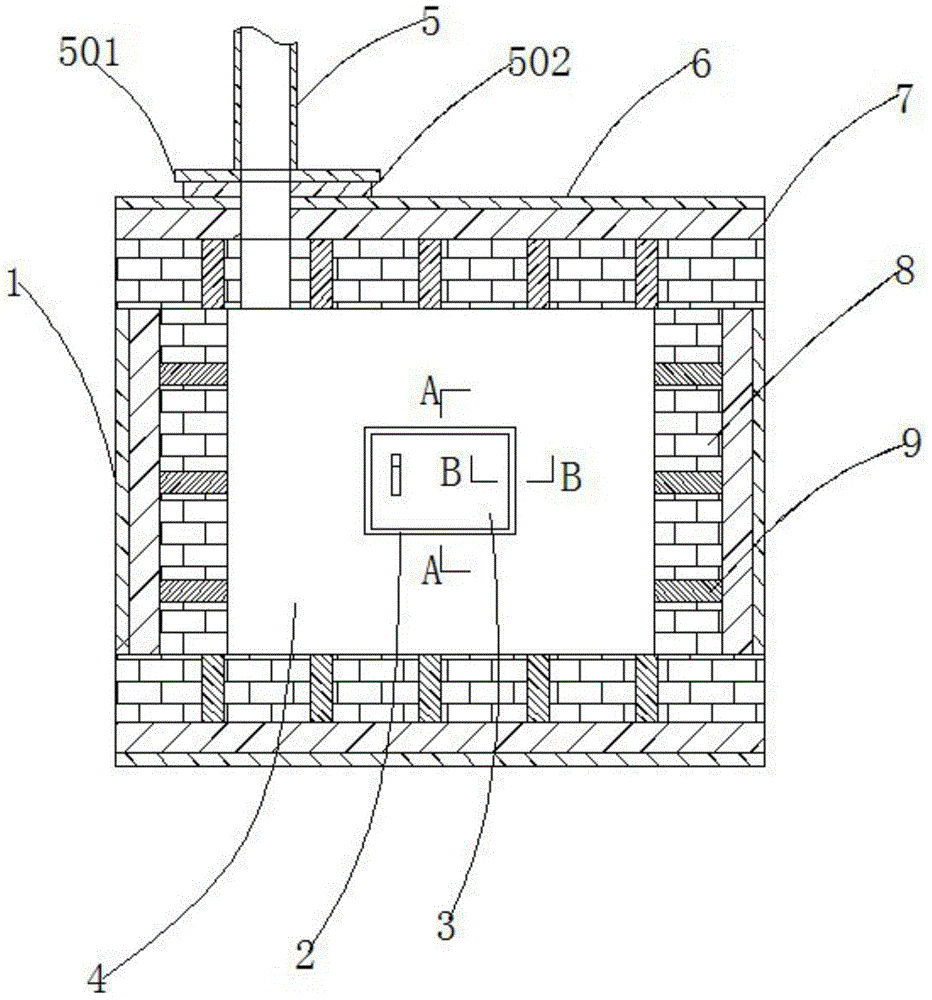

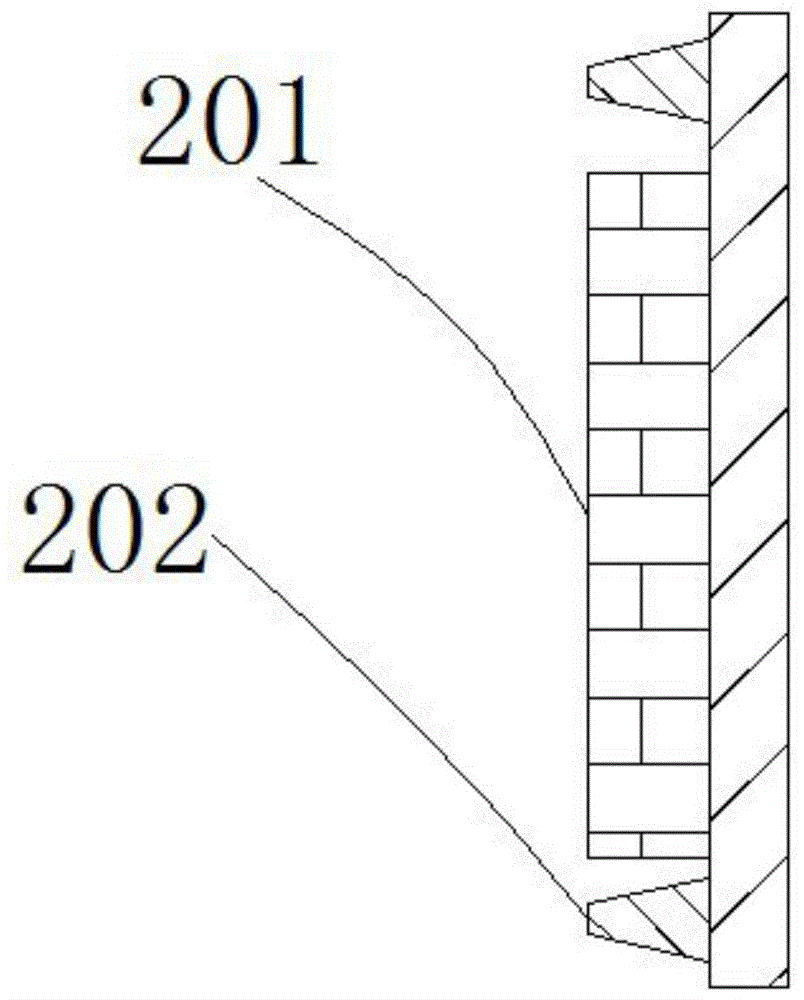

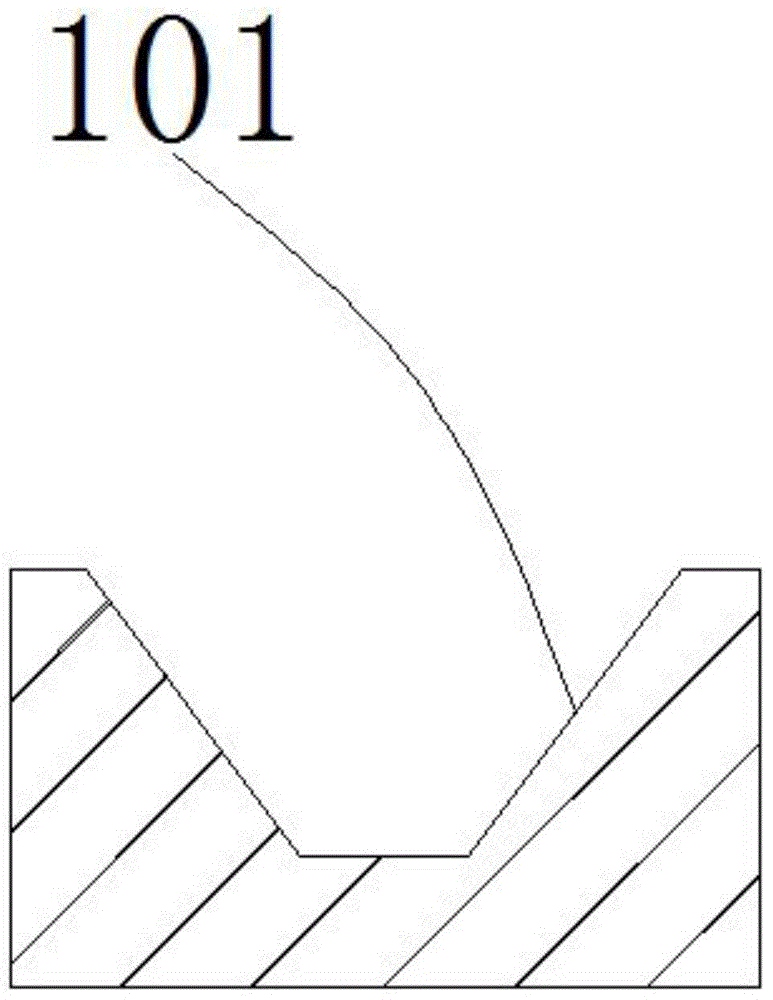

[0024] Such as figure 1 , figure 2 , image 3 As shown, including furnace body 1, furnace door 2, throwing port 3, combustion chamber 4, smoke exhaust pipe 5, sealing steel plate 6, heat insulation board 7, refractory wall 8, refractory cement 9, groove 101, sealing flange 501 , asbestos board 502, refractory brick 201, heat insulation strip 202, the sealing steel plate 6 is located outside the furnace body 1, the heat insulation plate 7 is located inside the sealing steel plate 6, and the refractory wall 8 is located inside the heat insulation plate 7, which is composed of severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com