Method for operating an ironing appliance comprising a vessel for generating pressurised steam

A technology of ironing equipment and working method, applied in the field of ironing equipment and work that implements the method, can solve problems such as appearance that does not attract users, the equipment becomes heavier and bulkier, and achieves simple and economical implementation and reduces equipment costs. The effect of water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Only elements necessary for an understanding of the invention are shown. In order to facilitate the reading of the drawings, the same elements in different drawings use the same symbols.

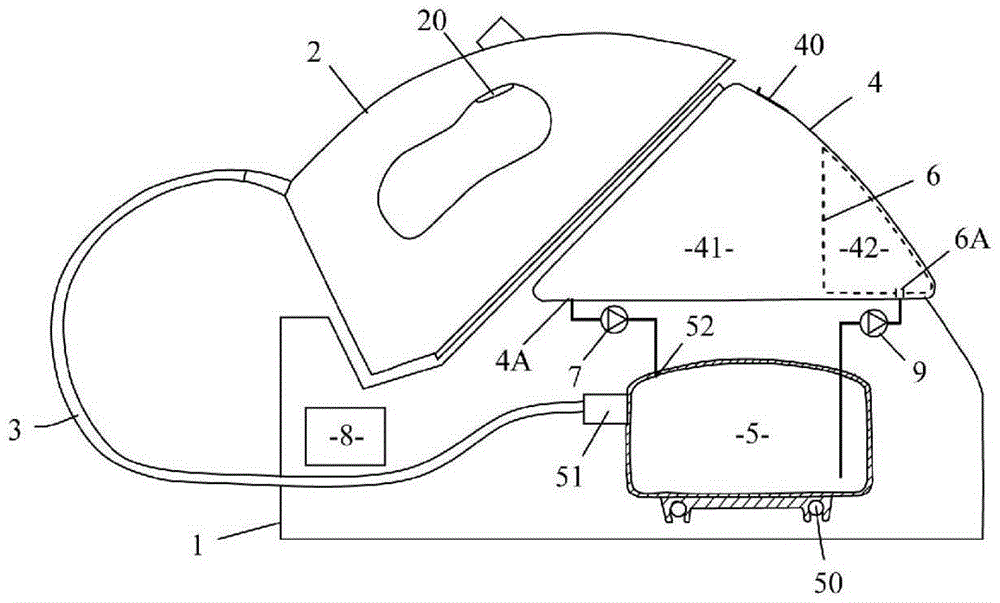

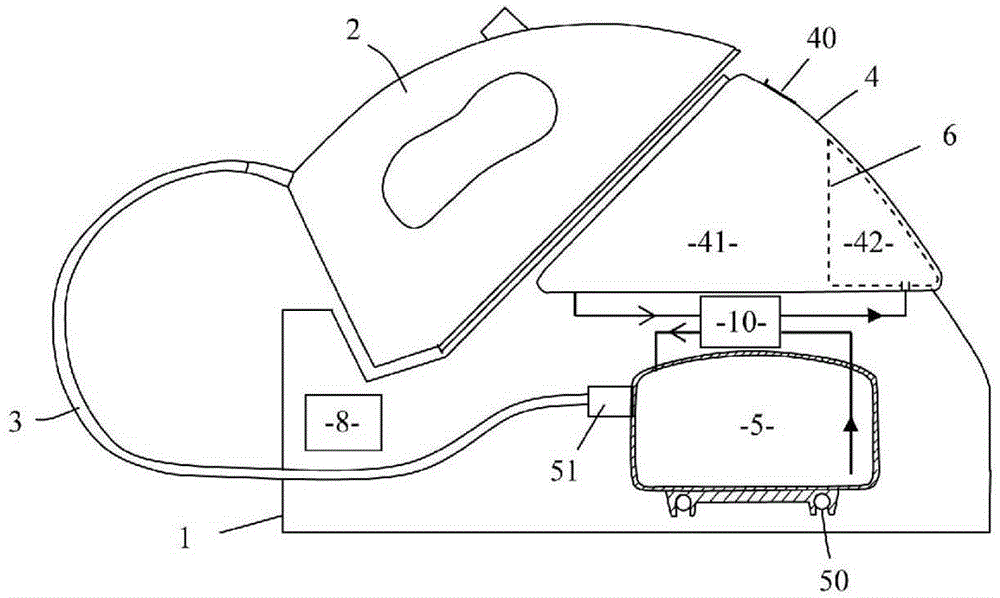

[0058] figure 1 An ironing device is schematically shown comprising a base 1 for generating steam and an iron 2 comprising a soleplate equipped with steam outlet holes, the iron 2 being connected to the base 1 by a cable 3 .

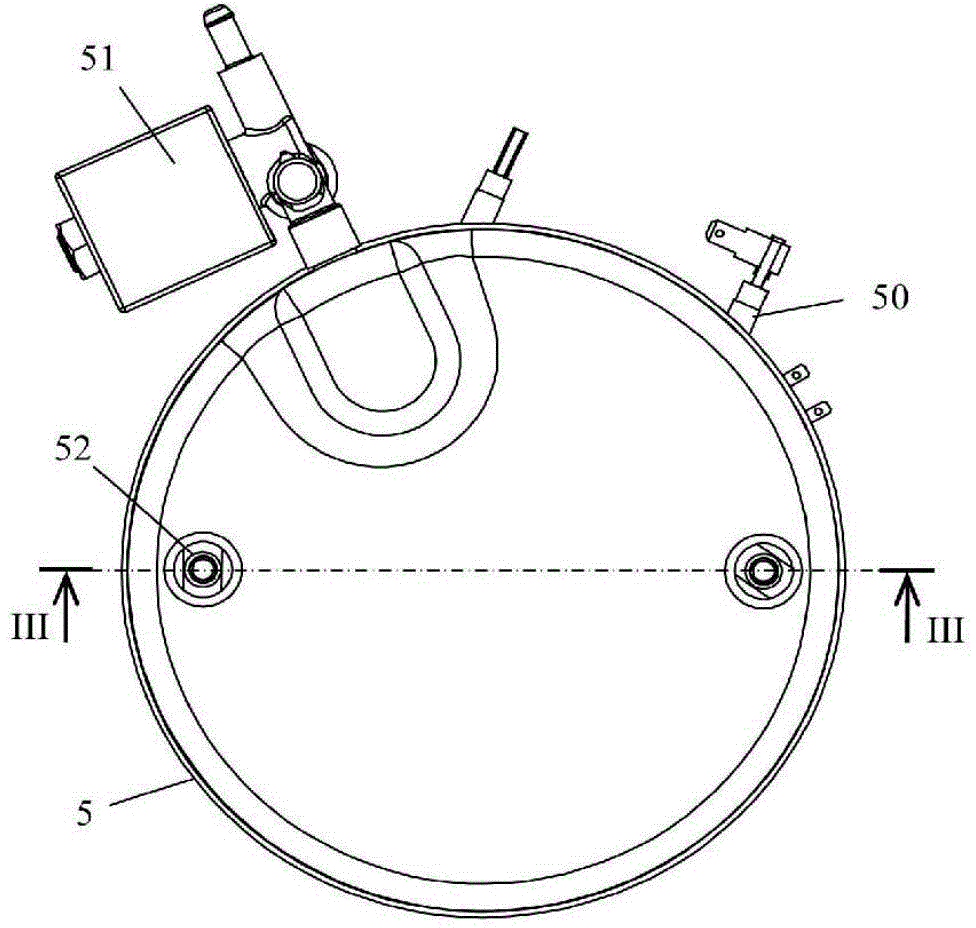

[0059] according to Figures 1 to 3 , the base 1 comprises a detachable container 4 with a capacity of about 2 liters, advantageously made of transparent plastic material, and a steam generator consisting of a cartridge 5 made of stainless steel having With a capacity of about 0.5 liters, the cartridge includes a heating resistor 50 with a power of about 1400 W, which allows steam to be generated at a pressure of about 4 to 6 bar. The cartridge 5 is connected to the iron by means of a steam conduit integrated in the cable 3 and comprises an electric valve 51 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com