Preparation method for nickel-based alloy ingot

A nickel-based alloy and nickel powder technology is applied in the field of preparation of nickel-based alloy ingots, which can solve the problems of difficulty in obtaining alloy ingots, unfavorable thermal-mechanical processing of alloy ingots, etc., and achieves the effects of ensuring composition uniformity and increasing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

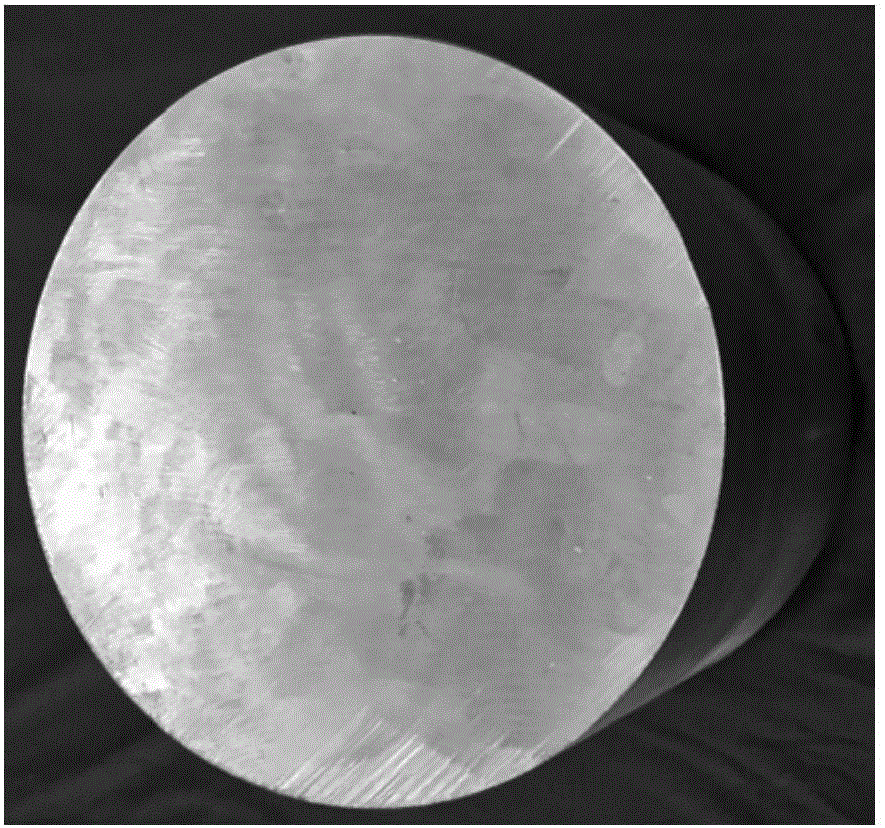

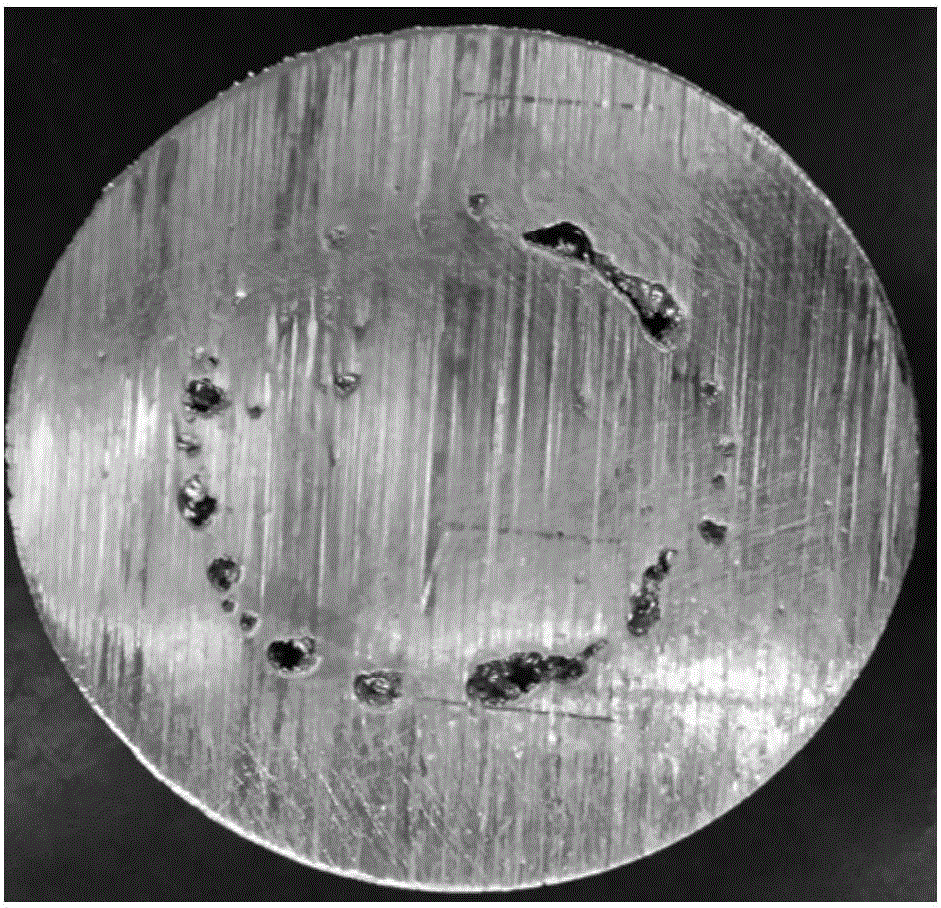

Image

Examples

Embodiment 1

[0021] This embodiment includes the following steps:

[0022] Step 1, uniformly mix nickel powder and metal element powder to obtain a mixed powder, then press the mixed powder to obtain a pre-sintered block; the metal element powder is tungsten powder, and the mass content of the tungsten powder in the mixed powder is 14 %, the balance is nickel powder;

[0023] Step 2: Sintering the pre-sintered block under the protection of hydrogen to obtain a pre-sintered block; the temperature of the sintering process is 1200° C., and the time is 2 hours;

[0024] Step 3. Place the pre-melted block described in step 2 in a medium-frequency induction melting furnace, and perform medium-frequency induction melting treatment under the condition that the pressure in the furnace is less than 10 Pa to obtain a nickel-based alloy melt with a temperature of 1800° C., and then melt the The nickel-based alloy melt is cast under the condition that the degree of vacuum is not greater than 100Pa to ...

Embodiment 2

[0044] This embodiment includes the following steps:

[0045] Step 1, uniformly mix nickel powder and metal element powder to obtain a mixed powder, then press the mixed powder to obtain a pre-sintered block; the metal element powder is tungsten powder, and the mass content of the tungsten powder in the mixed powder is 1 %, the balance is nickel powder;

[0046] Step 2: Sintering the pre-sintered block under the protection of hydrogen to obtain a pre-sintered block; the temperature of the sintering process is 1000° C., and the time is 4 hours;

[0047]Step 3. Place the pre-melted block described in step 2 in an intermediate frequency induction melting furnace, and carry out intermediate frequency induction melting treatment under the condition that the pressure in the furnace is less than 10 Pa to obtain a nickel-based alloy melt with a temperature of 1600° C. The nickel-based alloy melt is cast under the condition that the degree of vacuum is not greater than 100Pa to obtain...

Embodiment 3

[0054] This embodiment includes the following steps:

[0055] Step 1, uniformly mix nickel powder and metal element powder to obtain a mixed powder, then press the mixed powder to obtain a pre-sintered block; the metal element powder is tungsten powder, and the mass content of the tungsten powder in the mixed powder is 24 %, the balance is nickel powder;

[0056] Step 2, sintering the pre-sintered block under the protection of hydrogen to obtain a pre-fritted block; the temperature of the sintering process is 1100° C., and the time is 3 hours;

[0057] Step 3. Place the pre-melted block described in step 2 in an intermediate frequency induction melting furnace, and perform intermediate frequency induction melting treatment under the condition that the pressure in the furnace is less than 10Pa to obtain a nickel-based alloy melt with a temperature of 1700°C, and then melt the The nickel-based alloy melt is cast under the condition that the degree of vacuum is not greater than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com