Ammonia full recovery type copper ore high-efficiency chemical leaching device

A full recovery and leaching technology, applied in the improvement of process efficiency, chemical instruments and methods, steam condensation, etc., can solve problems such as explosion, easy leakage of ammonia, increase equipment investment, etc., to prevent leakage of ammonia, prevent deposition and blockage, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now in conjunction with accompanying drawing, the present invention is described in further detail.

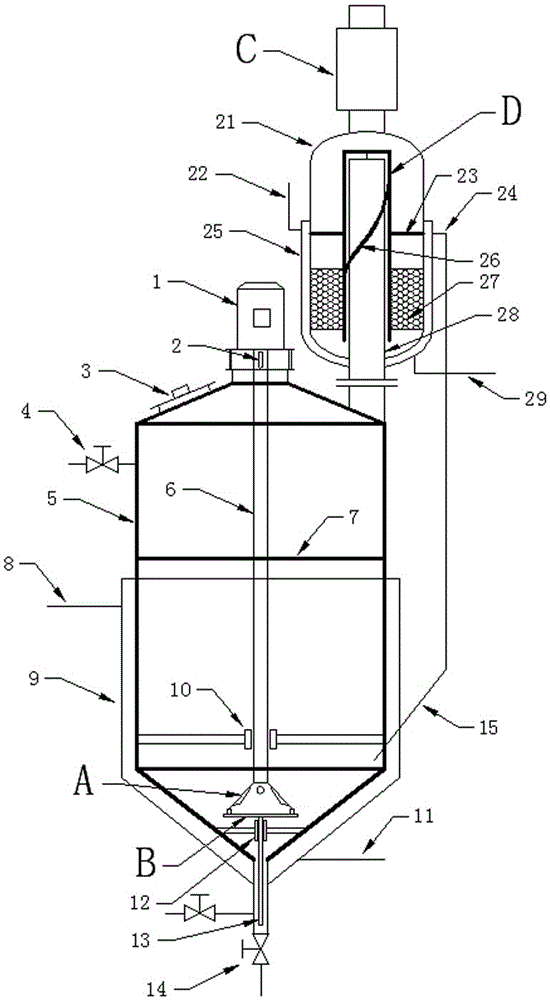

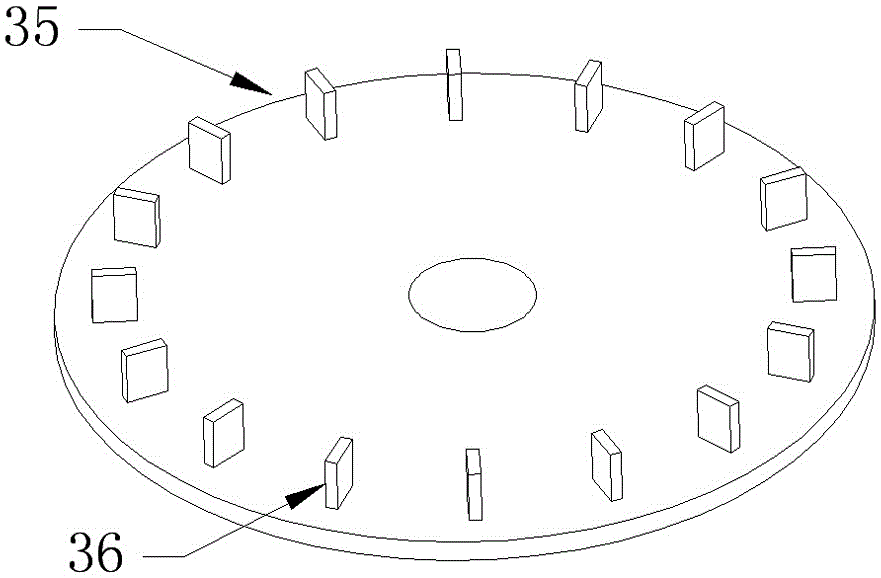

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 The shown ammonia full recovery type copper ore high-efficiency compound leaching device includes a compound leaching barrel 5 and a tail gas purifier 21, the intermediate pipe 28 of the compound leaching barrel 5 and the tail gas purifier 21 is detachably connected by a flange, and the tail gas purifier 21 is connected through an overflow The flow pipe 24 and the liquid return inclined pipe 15 are connected back to the compound leaching barrel 5; the compound leaching barrel 5 is provided with a manhole 3, a liquid inlet valve 4 and a heating jacket 9, and the stirring motor 1 is connected to the cone cover 31 through the hollow shaft 6 and then inserted into the compound leaching Inside the barrel 5, the cone cover 31 is provided with vanes 33 and liquid inlet holes 32, the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com