A fuel oil denitrification agent utilizing supramolecular inclusion complexation and its application method

A denitrifying agent and fuel technology, applied in chemical instruments and methods, refined hydrocarbon oil, petroleum industry, etc., can solve the problems of high cost, high environmental protection pressure, large loss of octane number, etc., and achieve low cost, mild conditions, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

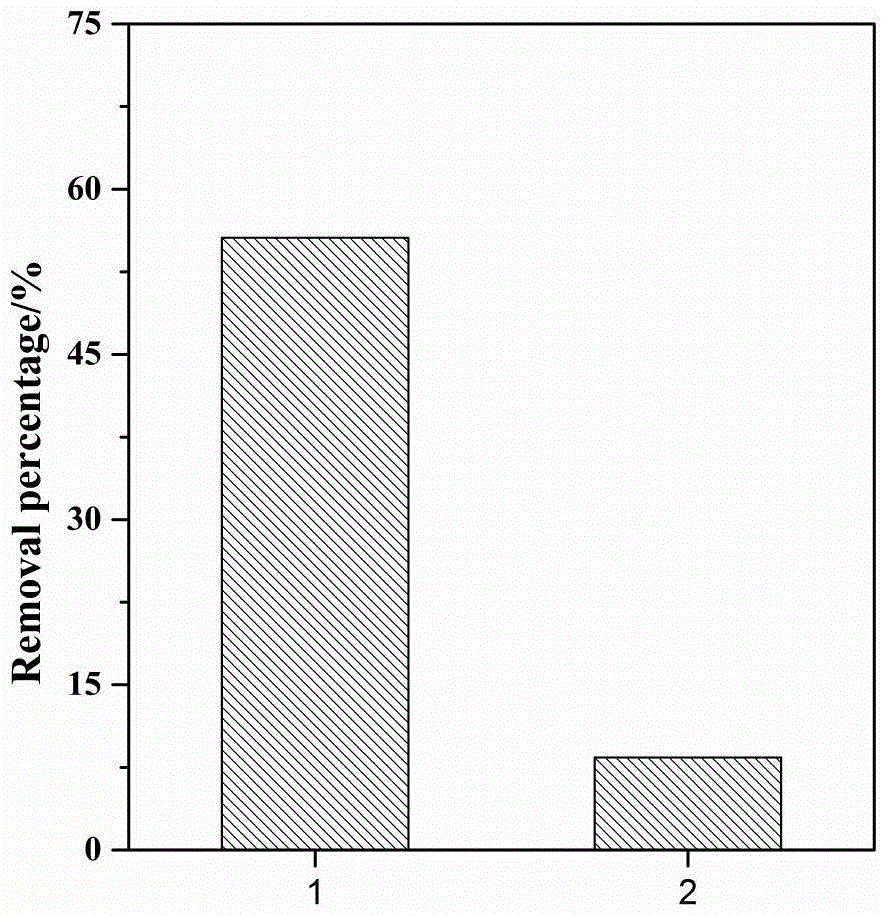

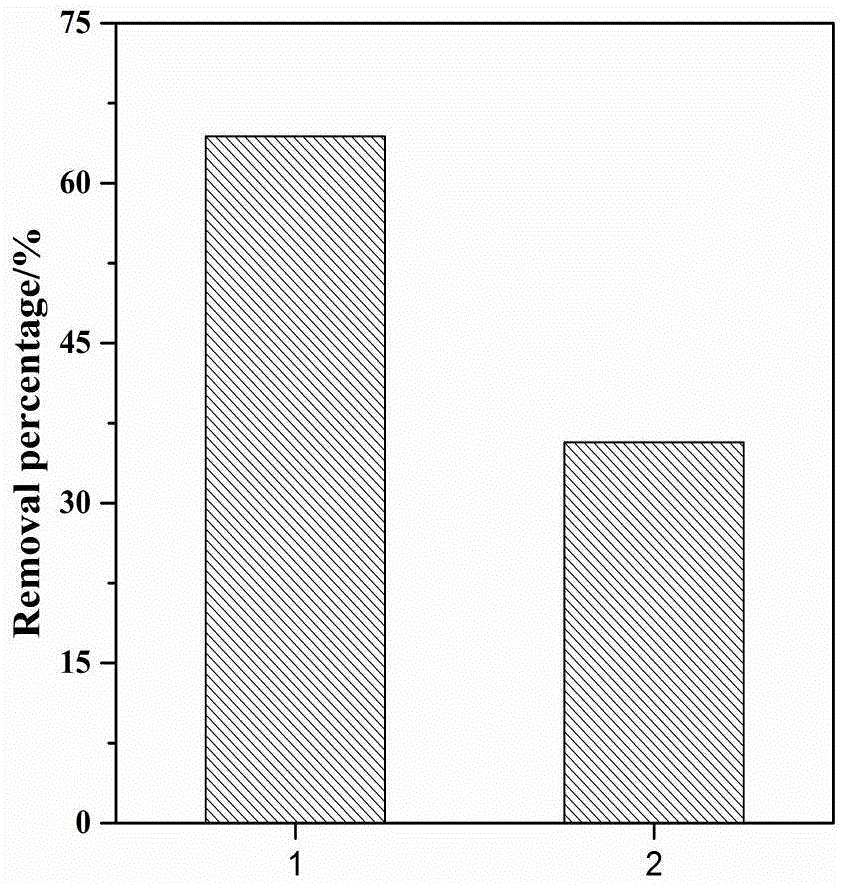

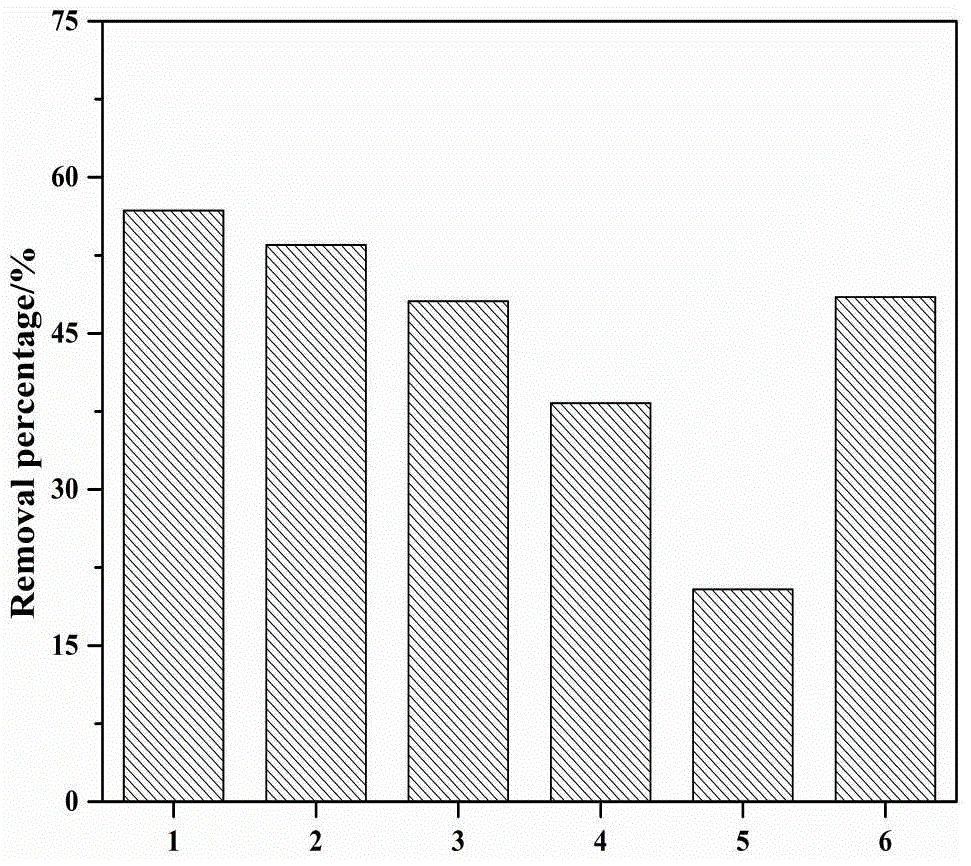

Embodiment 1

[0017] With 30ml of water as solvent, add 0.48g of β-cyclodextrin, stir at 40°C until completely dissolved, cool to room temperature, add 0.030g of stabilizer propylene glycol dimethyl ether, shake well, so that the content of β-cyclodextrin is 1.6%, and the stabilizer content is 0.1%. Take 30ml of this liquid denitrification agent and add it to 30ml of pyridine nitrogen content is 99.26μg·g -1 In the oil products, the volume ratio of the agent to oil was 1:1. After stirring at a constant temperature of 25°C for 20 minutes, the oil layer was separated, and the nitrogen removal rate of nitrogen-containing compounds was 74.8%.

Embodiment 2

[0019] Take 10ml of water as solvent, add 0.05g of β-cyclodextrin, stir at 30°C until completely dissolved, cool to room temperature, add 0.010g of stabilizer propylene glycol dimethyl ether, shake well, so that the content of β-cyclodextrin 0.5%, the stabilizer content is 0.1%. Take 10ml of this liquid denitrification agent and add it to 30ml of pyridine nitrogen content is 99.26μg·g -1 In the oil product, the volume ratio of agent to oil was 1:3, and after stirring at a constant temperature of 30°C for 10 minutes, the oil layer was separated, and the nitrogen removal rate of nitrogen-containing compounds was 42.4%.

Embodiment 3

[0021] Using 15ml of water as a solvent, add 0.18g of methyl β-cyclodextrin, stir at 30°C until completely dissolved, cool to room temperature, add 0.010g of stabilizer propylene glycol monomethyl ether, so that methyl β-cyclodextrin The content of the stabilizer is 1.2%, and the content of the stabilizer is 0.1%. Take 15ml of this liquid denitrification agent and add it to 30ml of pyridine nitrogen content is 99.26μg·g -1 In the oil product, the volume ratio of agent to oil was 1:2. After stirring at a constant temperature of 30°C for 10 minutes, the oil layer was separated, and the nitrogen removal rate of nitrogen-containing compounds was 60.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com