3D printing material based on fused deposition manufacturing process, printing method and printing device

A fused deposition manufacturing and 3D printing technology, applied in the field of 3D printing, can solve the problems of expensive printing materials, gas pollution to the environment, and human body harm, and achieve the effects of simple manufacturing process, low price, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

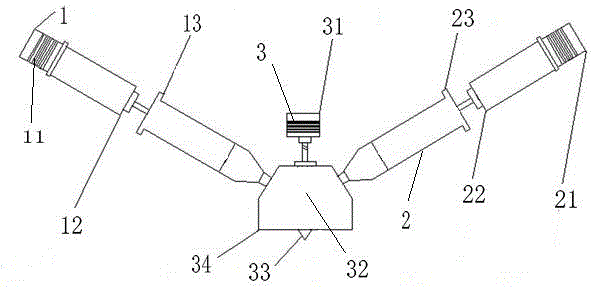

Image

Examples

specific example 1

[0045] The 3D material of this embodiment is made up of base material and curing agent;

[0046] The composition and mass percentage of the basic materials are as follows:

[0047] Resole phenolic resin 70%, toughening agent 16%, organic ester 10%, silane coupling agent 2%, lubricant 2%;

[0048] The composition and mass percentage of curing agent are as follows:

[0049] 65% phenolsulfonic acid, 25% phosphoric acid, 10% p-toluenesulfonic acid.

[0050] The 3D printing method using 3D printing materials in this embodiment, the steps of the method are as follows:

[0051] (1) Put the material of the basic material into the JB-200 electric mixer, the stirring time is 20min, and the stirring speed is 140r / min. An appropriate amount of ethanol solution with a concentration of 98% can be added to control the viscosity of the basic material at about 1400cp.

[0052] (2) Put the curing agent into the FRP mixing tank, the stirring time is 15min, the stirring speed is 35r / min, and i...

specific example 2

[0055] The 3D material of this embodiment is made up of base material and curing agent;

[0056] The composition and mass percentage of the basic materials are as follows:

[0057] Resole phenolic resin 72%, toughening agent 15%, organic ester 10%, silane coupling agent 2%, lubricant 1%;

[0058] The composition and mass percentage of curing agent are as follows:

[0059] 70% phenolsulfonic acid, 20% phosphoric acid, 10% p-toluenesulfonic acid.

[0060] The 3D printing method using 3D printing materials in this embodiment, the steps of the method are as follows:

[0061] (1) Put the material of the basic material into the JB-200 electric mixer, the stirring time is 25min, and the stirring speed is 130r / min. An appropriate amount of ethanol solution with a concentration of 98% can be added to control the viscosity of the basic material at about 1400cp.

[0062] (2) Put the curing agent material into the FRP mixing tank, the stirring time is 20min, the stirring speed is 30r / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com