Edible condiment packing bag as well as preparation method and application thereof

A technology for packaging bags and seasonings, which is applied to edible seasoning packaging bags and the fields of preparation and application thereof, can solve the problems of high raw material price, restricted gelatin acceptability, etc., and achieves simple preparation method, wide application range, and no pollution. The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

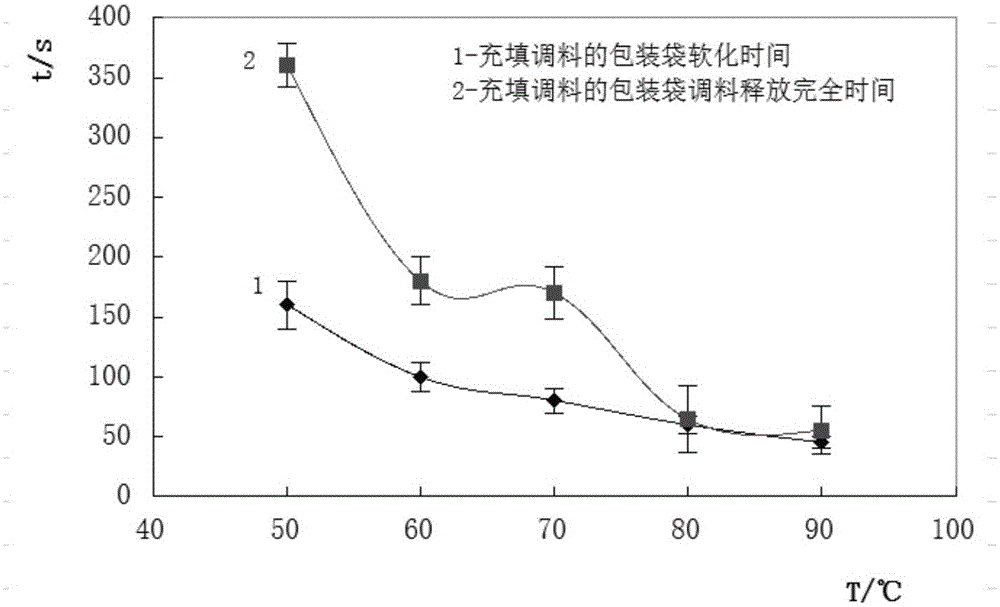

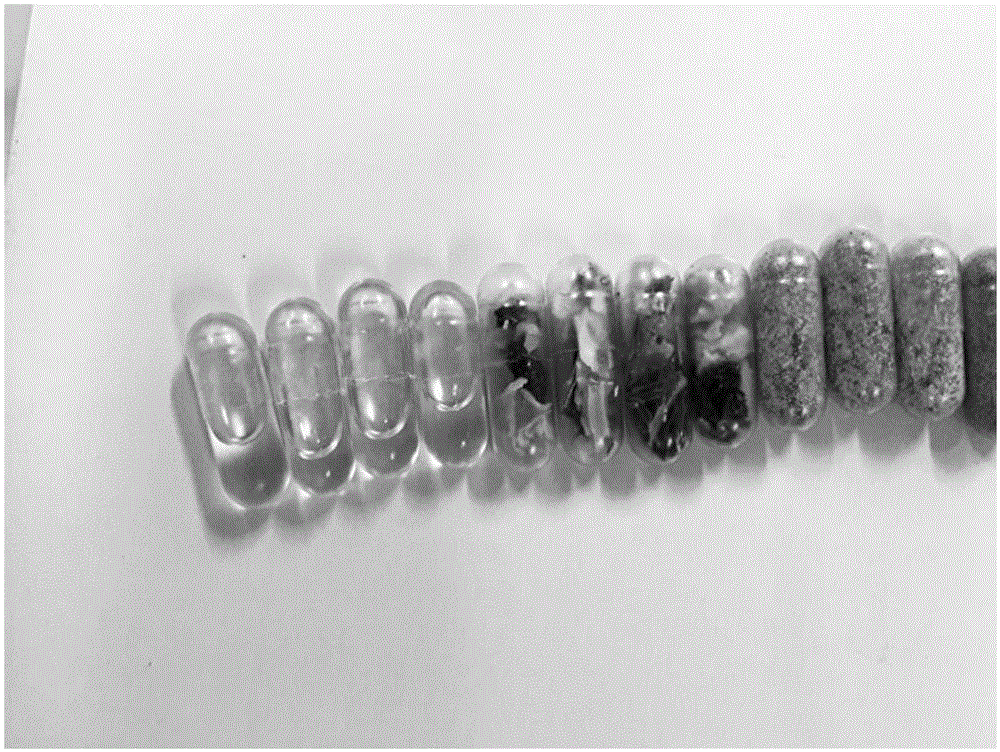

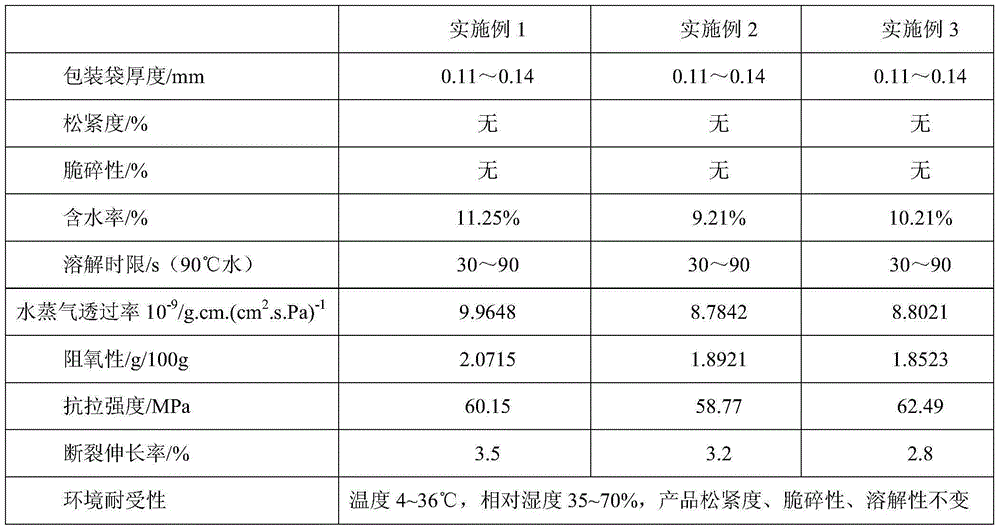

[0026] The preparation method of the edible packaging bag of embodiment 1 comprises the following steps:

[0027]1) Ingredients: weigh the solid components except dietary fiber pulp and deionized water according to the weight ratio of 17.34:100. Among them, weigh 6.5 kg of acetate starch, 4.55 kg of hydroxypropyl distarch phosphate, oxidized 0.025 kg of hydroxypropyl starch, 0.024 kg of hydroxypropyl starch, 0.21 kg of sodium alginate, 1.1 kg of carrageenan, 0.01 kg of agar, 3.5 kg of hydroxypropyl methylcellulose, 0.01 kg of potassium chloride, 0.29 kg of isomalt, 0.50 kg of glycerin, 0.12 kg of sodium polyacrylate, for subsequent use; another 0.5 kg of corn was weighed, added 6.5 liters of hot water and refined with a refiner, filtered with a 150-mesh sieve to obtain corn fiber pulp, for subsequent use;

[0028] 2) Glue making solution: After mixing the solid components except corn fiber slurry, disperse with 30% deionized water, and grind with colloid until there are no par...

Embodiment 2

[0032] The preparation method of the edible packaging bag of embodiment 2 comprises the following steps:

[0033] 1) Ingredients: weigh the solid components except dietary fiber pulp and deionized water according to the weight ratio of 20:120, wherein, weigh 7.95 kg of acetate starch, 5 kg of hydroxypropyl distarch phosphate, oxidized Hydroxypropyl starch 0.34 kg, sodium alginate 0.318 kg, carrageenan 1.204 kg, hydroxypropyl methylcellulose 3.3 kg, carboxymethyl cellulose 0.063 kg, potassium chloride 0.005 kg, isomalt 0.92 kg, sodium polyacrylate 0.10 kg, for subsequent use; Another 0.8 kg of konjaku is taken by weighing, after adding 15 liters of hot water and defibrating with a refiner, filter with a 150 mesh screen to obtain konjac fiber pulp, for subsequent use;

[0034] 2) Glue making solution: After mixing the solid components except konjac fiber pulp, disperse with 30% deionized water, and grind with colloid until there are no particles, then add konjac fiber pulp and m...

Embodiment 3

[0038] The preparation method of the edible packaging bag of embodiment 3 comprises the following steps:

[0039] 1) Ingredients: weigh the solid components other than dietary fiber pulp and deionized water according to the weight ratio of 14.5:80. Among them, weigh 5.7 kg of acetate starch, 3.2 kg of oxidized hydroxypropyl starch, hydroxypropyl starch Distarch phosphate 0.25 kg, sodium alginate 0.4 kg, carrageenan 1 kg, hydroxypropyl methylcellulose 2.4 kg, potassium chloride 0.01 kg, isomalt 0.2 kg, glycerin 0.24 kg, chitosan 0.55 kg, spare In addition, take 0.35 kilograms of oats, add 5 liters of hot water and use a refiner to refine, filter with a 180-mesh sieve to obtain oat fiber pulp, and set aside;

[0040] 2) Glue making solution: After mixing the solid components except oat fiber pulp, disperse with 30% deionized water, and grind with colloid until there are no particles, then add oat fiber pulp and mix evenly to obtain plant Slurry, then heat the remaining deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com