Method for preparing sodium carboxymethyl cellulose by utilizing degummed seaweed residues

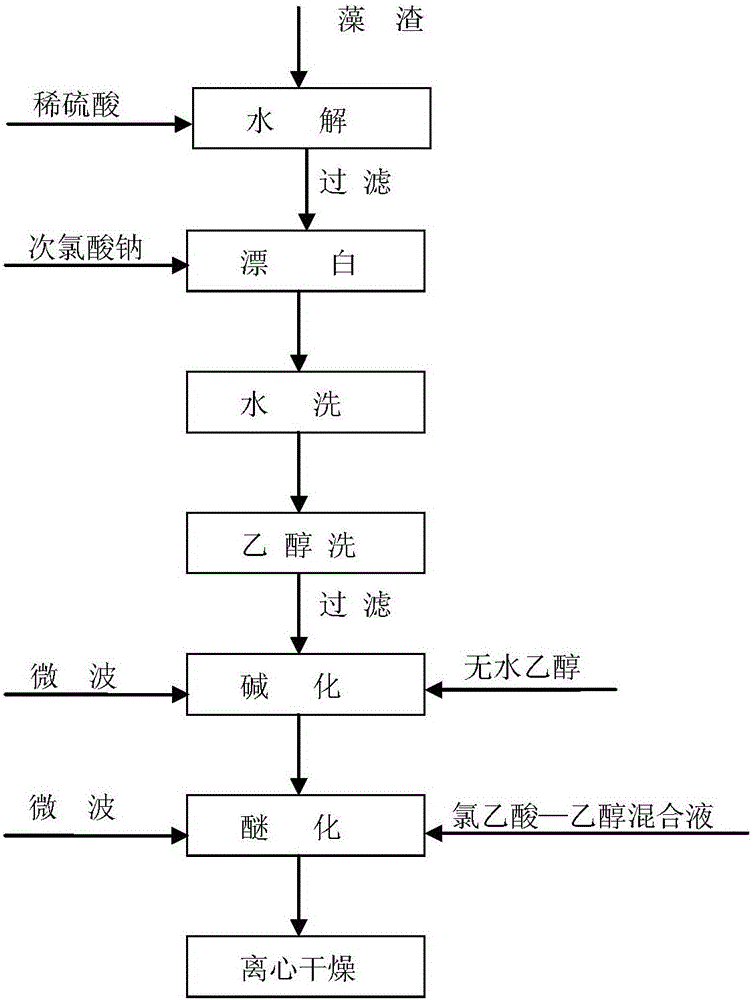

A technology for sodium carboxymethyl cellulose and seaweed residue is applied in the field of preparing sodium carboxymethyl cellulose and treating the waste residue of seaweed from which seaweed gum has been extracted by microwave technology, which can solve the problem that the product performance is difficult to control and the combination of difficult etherifying agents can be solved. , affecting the degree of substitution of the final product, to reduce the reaction time, increase the frequency of molecular collisions, and achieve the effect of sustainable development strategies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of present embodiment sodium carboxymethyl cellulose specifically comprises the following steps:

[0040] Step 1, hydrolysis, adding the degummed seaweed residue to dilute sulfuric acid solution, the quality of the dilute sulfuric acid is 20 times the mass of the degummed seaweed residue, the mass fraction of the dilute sulfuric acid solution is 1.5%, heating and hydrolyzing for 2 hours under boiling conditions, filtering, collect algae residue;

[0041] Step 2, bleaching, adding a sodium hypochlorite solution with an available chlorine content of 10% to the algal residue obtained in step 1 to bleach until the algal residue is white and loose, usually for 15-30 minutes;

[0042] Step 3, washing with water, washing the algae residue after bleaching in step 2, and filtering it with a 40-mesh filter, thereby removing the impurity part larger than 40 mesh in the degummed seaweed residue, and collecting the algae residue smaller than 40 mesh to enter t...

Embodiment 2

[0049] The difference from Example 1 is:

[0050] In step 1, the mass fraction of dilute sulfuric acid solution is 3.0%.

[0051] Performance testing: After the product is dried, the product performance testing is carried out, and the degree of substitution is 0.62.

Embodiment 3

[0053] The difference from Example 1 is:

[0054] In step 1, the mass fraction of dilute sulfuric acid solution is 5.0%.

[0055] Performance testing: After the product is dried, the product performance testing is carried out, and the degree of substitution is 0.15.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com