N-(2)-L-alanyl-L-glutamine compound prepared by adopting particle crystal form optimization technique and preparation thereof

A glutamine and compound technology, applied in the field of N--L-alanyl-L-glutamine compounds and their preparations, can solve the problems of lack of crystal morphology optimization process, many steps, and low overall yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

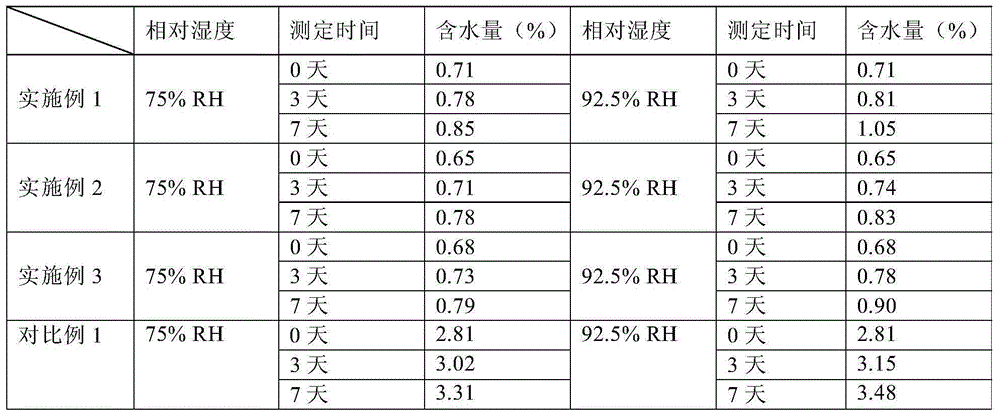

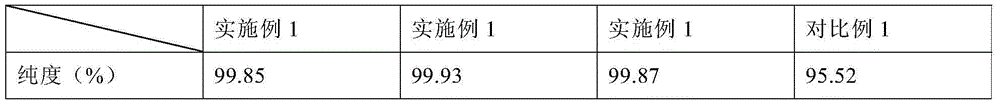

Embodiment 1

[0040] Example 1 Preparation of N-(2)-L-alanyl-L-glutamine compound

[0041] 1. Synthesis of Boc-L-Alanine

[0042] Add 500.15g of water, 50.03g of 2-methyltetrahydrofuran, 5.01g of L-alanine to the reactor, add 1.21g of sodium hydroxide and 6.03g of di-tert-butyl dicarbonate at 0°C, and react at 18°C for 10 hours. Adjust the pH to 2.1 with dilute hydrochloric acid, extract 3 times with ethyl acetate, wash 3 times with saturated brine, add anhydrous Na to the organic phase 2 SO 4 Drying for 5 hours, filtering, and rotary evaporation at a temperature of 30° C. and a pressure of -0.5 MPa to obtain 4.75 g of Boc-L-alanine with a yield of 94.81%.

[0043] 2. Synthesis of N-carboxyl anhydride

[0044] Mix 4.50g of Boc-L-alanine, 18.02g of bis(trichloromethyl)carbonate, and 36.53g of 2-methyltetrahydrofuran, react at 0°C for 2 hours, and spin down at a temperature of 30°C and a pressure of -0.5MPa. Evaporate and concentrate to about 30ml, add 80ml of n-hexane, let stand for 20min, filter...

Embodiment 2

[0048] Example 2 Preparation of N-(2)-L-alanyl-L-glutamine compound

[0049] 1. Synthesis of Boc-L-Alanine

[0050] Add 500.05g of water, 50.12g of 2-methyltetrahydrofuran, 5.00g of L-alanine to the reactor, add 1.50g of sodium hydroxide and 6.13g of di-tert-butyl dicarbonate at 0℃, and react at 17℃ for 10 hours , Adjust the pH to 1.8 with dilute hydrochloric acid, extract 3 times with ethyl acetate, wash 3 times with saturated brine, add anhydrous Na to the organic phase 2 SO 4 After drying for 5 hours, filtering, and rotary evaporation at a temperature of 30° C. and a pressure of -0.5 MPa to obtain 4.83 g of Boc-L-alanine with a yield of 96.60%.

[0051] 2. Synthesis of N-carboxyl anhydride

[0052] Mix Boc-L-alanine 4.50g, bis(trichloromethyl)carbonate 18.13g, 2-methyltetrahydrofuran 35.08g, and react at 0°C for 1.5 hours. At a temperature of 30°C and a pressure of -0.5MPa, Concentrate by rotary evaporation to about 30ml, add 80ml of n-hexane, let stand for 20min, filter with suc...

Embodiment 3

[0056] Example 3: Preparation of N-(2)-L-alanyl-L-glutamine compound

[0057] 1. Synthesis of Boc-L-Alanine

[0058] Add 500.51g of water, 50.35g of 2-methyltetrahydrofuran, 5.00g of L-alanine to the reactor, add 2.03g of sodium hydroxide and 6.02g of di-tert-butyl dicarbonate at 2°C, and react at 16°C for 12 hours , Adjust the pH to 2.5 with dilute hydrochloric acid, extract 3 times with ethyl acetate, wash 3 times with saturated brine, add anhydrous Na to the organic phase 2 SO 4 After drying for 5 hours, filtering, and rotary evaporation at a temperature of 30° C. and a pressure of -0.5 MPa to obtain 4.77 g of Boc-L-alanine with a yield of 95.40%.

[0059] 2. Synthesis of N-carboxyl anhydride

[0060] Mix 4.53g of Boc-L-alanine, 18.04g of bis(trichloromethyl)carbonate, and 36.15g of 2-methyltetrahydrofuran, and react at 1°C for 2 hours. At a temperature of 30°C and a pressure of -0.5MPa, Concentrate by rotary evaporation to about 30ml, add 80ml of n-hexane, let stand for 20min, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com