A kind of preparation method of three-(2-chloroisopropyl) phosphate

A chloroisopropyl, phosphoric acid ester technology, applied in the direction of phosphorus organic compounds, etc., can solve the problem of not mentioning the root cause

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] First pump 4600 kg of phosphorus oxychloride into the 5000L stirred phosphorus oxychloride measuring kettle equipped with a solid feeder, then add 15 kg of anhydrous aluminum trichloride catalyst through the solid feeder, stir and dissolve at room temperature To obtain phosphorus oxychloride solution, propylene oxide is continuously passed through a dehydration tower filled with dehydrating agent calcium oxide and collected into a total of 5300 kilograms in a 10000L metering tank. After testing, the water content of propylene oxide in the metering tank is 28PPM. Add the phosphorus oxychloride solution containing the catalyst and the dehydrated propylene oxide into the mixture at the same time, the reaction temperature is controlled at 65°C during the feeding process, and the feeding speed of the two is controlled during the feeding process so that the weight ratio is phosphorus oxychloride: propylene oxide =1:1.152, after adding the materials at the same time in proporti...

Embodiment 2-5

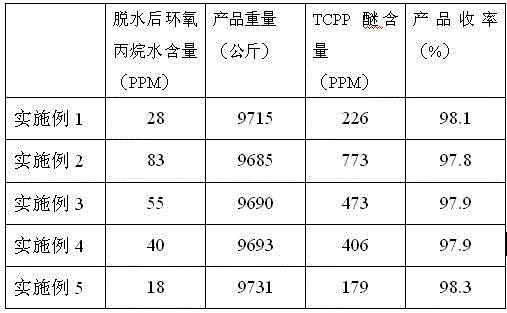

[0036] Except using propylene oxide with different water content after dehydration by different dehydrating agents, other operations repeat Example 1, and the final results are shown in the following table:

[0037] Table 1. Effect of propylene oxide water content on product yield and TCPP ether content

[0038]

[0039] As can be seen from the data of Examples 1-5 of the present invention and comparative examples, after adopting the method of the present invention, TCPP ether in the product obtained obviously reduces, and product yield also has certain improvement simultaneously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com