Method for preparing benzfluorenone compound by palladium as catalyst

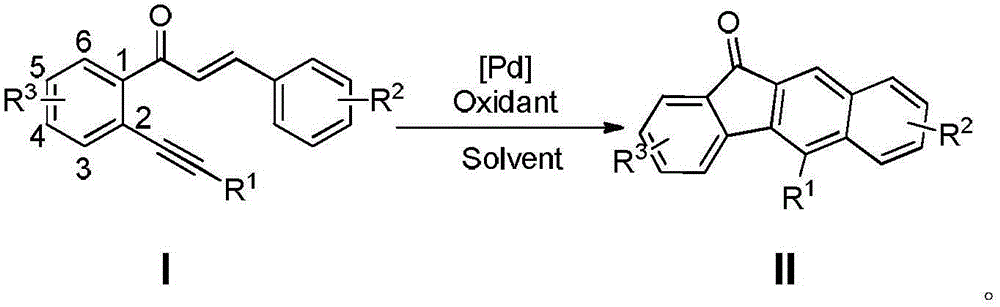

The technology of benzofluorenone and palladium catalyst is applied in the synthesis field of organic compounds, can solve the problems of difficult preparation of reaction raw materials, numerous reaction steps, long reaction time and the like, and achieves high substrate universality, easy preparation and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

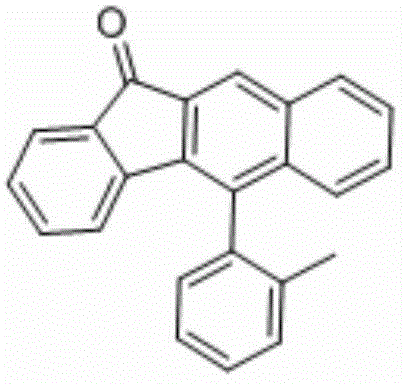

[0026] Example 1: Synthesis of 5-phenylbenzofluorenone using 3-phenyl-1-(2'-o-methylphenylethynyl)phenyl-2-allyl ketone as raw material

[0027]

[0028] Add 0.2mmol of 3-phenyl-1-(2'-o-methylphenylethynyl)phenyl-2-allyl ketone, 0.01mmol of Pd / C and 0.4mmol of Selectfluor into a 10mL pressure-resistant sealed container in sequence, and then add 2.0 mL of acetonitrile. Stir the reaction at room temperature, TLC follow-up detection, after 3 hours of reaction, the reaction solution is diluted with 10mL of dichloromethane, filtered to obtain the clear liquid, and the solvent is removed by column chromatography (eluent ratio: sherwood oil to acetic acid Ethyl ester (volume ratio 15:1) was separated, the eluate was collected, and the solvent was distilled off to obtain 5-o-methylphenylbenzofluorenone as an orange solid with a yield of 75%.

[0029] Orange solid; mp213-215℃; 1 HNMR (500MHz, CDCl 3 ): δ=8.26(s, 1H), 8.00-7.96(m, 1H), 7.76(dd, J 1 =6.0Hz,J 2 =1.0Hz, 1H), 7.52-7...

Embodiment 2

[0030] Example 2: Synthesis of 5-phenylbenzofluorenone using 3-phenyl-1-(2'-o-methylphenylethynyl)phenyl-2-allyl ketone as raw material

[0031]

[0032] 0.2mmol of 3-phenyl-1-(2'-o-methylphenylethynyl)phenyl-2-allyl ketone, 0.02mmol of Pd / C and 1-chloromethyl-4-fluoro-1,4-di Add 0.6mmol of azabicyclo[2.2.2]octane di(hexafluorophosphate) salt into a 10mL pressure-resistant sealed container in turn, and then add 2.0mL of chloroform. Stir the reaction at room temperature, TLC follow-up detection, after 3 hours of reaction, the reaction solution is diluted with 10mL of dichloromethane, filtered to obtain the clear liquid, and the solvent is removed by column chromatography (eluent ratio: sherwood oil to acetic acid Ethyl ester (volume ratio 15:1) was separated, the eluate was collected, and the solvent was distilled off to obtain 5-o-methylphenylbenzofluorenone as an orange solid with a yield of 70%.

[0033] Orange solid; mp213-215℃; 1 HNMR (500MHz, CDCl 3 ): δ=8.26(s, 1H)...

Embodiment 3

[0034] Example 3: Synthesis of 5-phenylbenzofluorenone using 3-phenyl-1-(2'-o-methylphenylethynyl)phenyl-2-allyl ketone as raw material

[0035]

[0036] Add 0.2mmol of 3-phenyl-1-(2'-o-methylphenylethynyl)phenyl-2-allyl ketone, 0.016mmol of Pd / C and 0.4mmol of N-fluoropyridine trifluoromethanesulfonate to 10mL in sequence In a pressure-proof airtight container, add 2.0 mL of dichloromethane. Stir the reaction at room temperature, TLC follow-up detection, after 3 hours of reaction, the reaction solution is diluted with 10mL of dichloromethane, filtered to obtain the clear liquid, and the solvent is removed by column chromatography (eluent ratio: sherwood oil to acetic acid Ethyl ester (volume ratio 15:1) was separated, the eluate was collected, and the solvent was distilled off to obtain 5-o-methylphenylbenzofluorenone as an orange solid with a yield of 70%.

[0037] Orange solid; mp213-215℃; 1 HNMR (500MHz, CDCl 3 ): δ=8.26(s, 1H), 8.00-7.96(m, 1H), 7.76(dd, J 1 =6.0Hz,J...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com