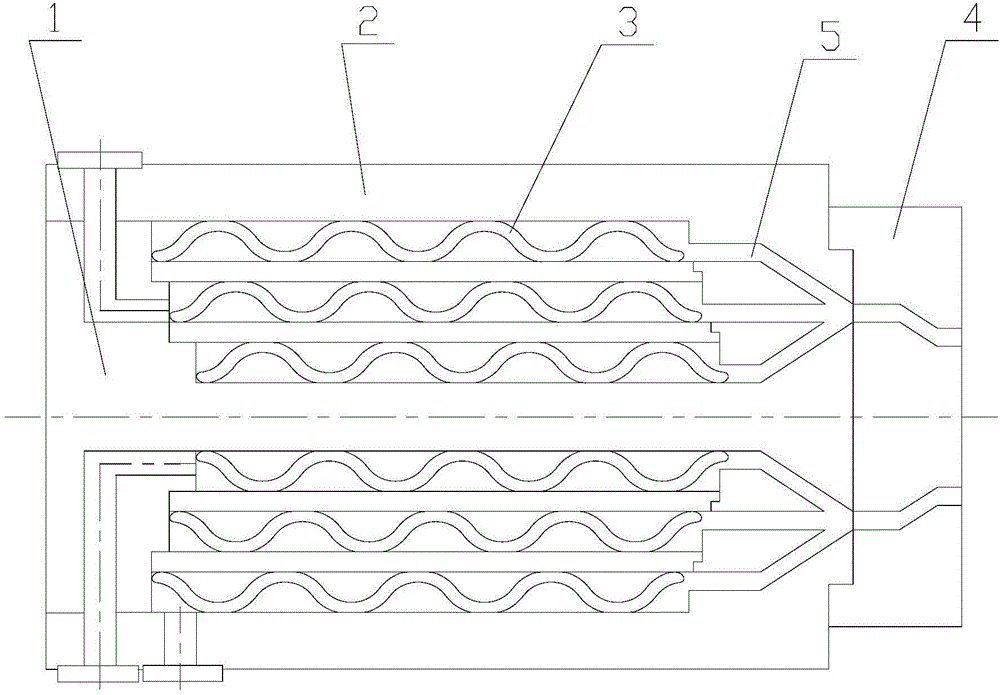

Flow equalizing method and device for rotor driven by melt extrusion pressure and provided with internal and external screw flights

A technology of melt extrusion and helicoidal rotors, which is applied in household appliances, other household appliances, applications, etc., can solve the problems of uneven flow and distribution of polymer melts, achieve wide application range, reduce energy consumption, and be easy to manufacture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

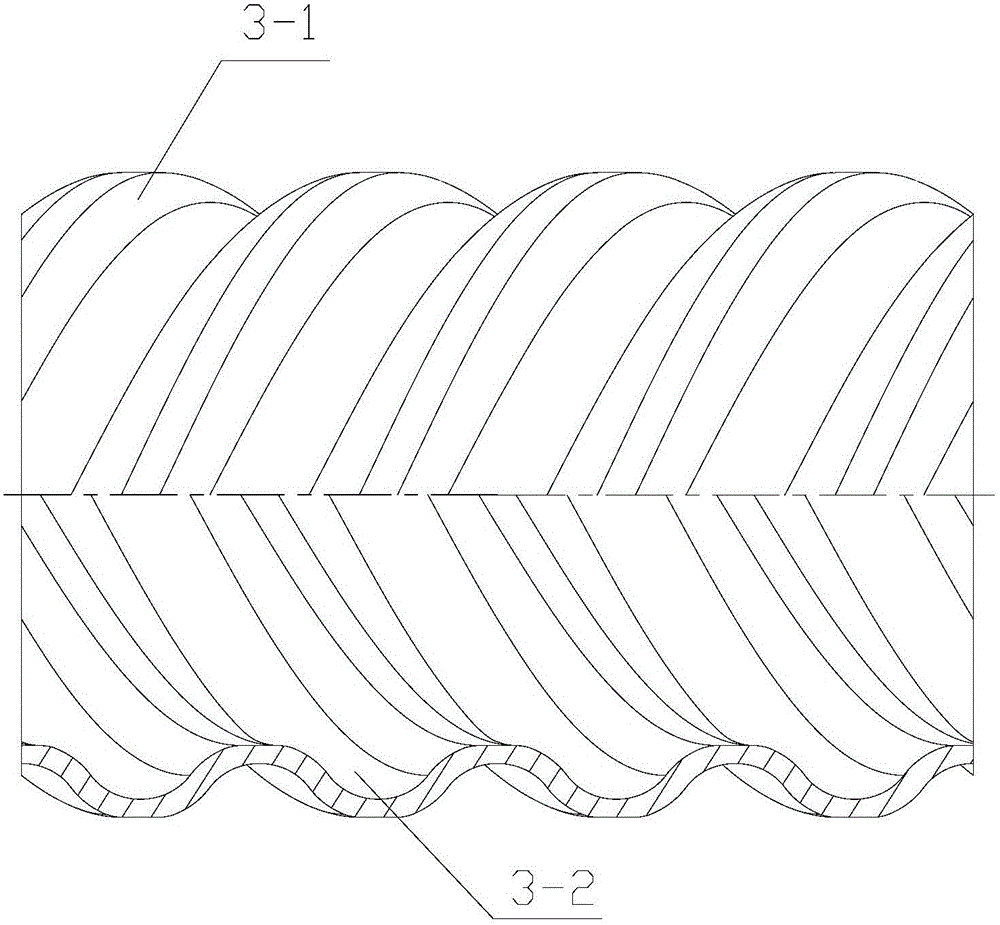

[0023] This embodiment is a melt extrusion pressure-driven flow sharing method with inner and outer helicoidal rotors. After the polymer melt from the extruder is shielded in the input area of the rotor, it is circularly flowed along the inner and outer helical ribs of the rotor. (i.e. circumferential) shunt flow, force the rotor to rotate after being filled with internal and external screw ribs, forming a multi-head spiral, and transport it to the output area of the rotor with the rotation of the rotor, so that the extrusion speed is uniform along the circumferential direction of the rotor (i.e. circumferential direction) distributed. Among them, when the polymer melt flows through the rotor, the original beam-shaped melt is divided into several strands by the rotor, and eddy currents are generated when entering or flowing out of the grooves on the rotor, resulting in a change in the flow direction, thereby promoting polymerization Melting of the unmelted solid phase in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com