LNG (Liquefied Natural Gas) cold energy efficient mixed refrigerant power generation method

A technology of mixing refrigerants and refrigerants, which is applied in ocean energy power generation, machines/engines, steam engine installations, etc., and can solve problems such as complex systems and poor adjustment performance under variable working conditions of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

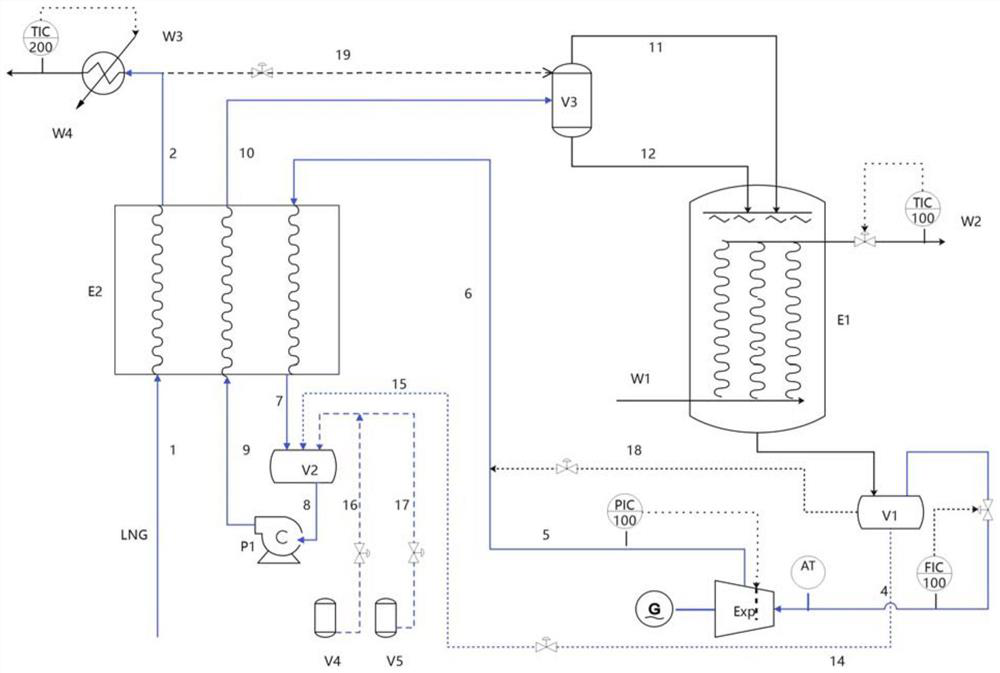

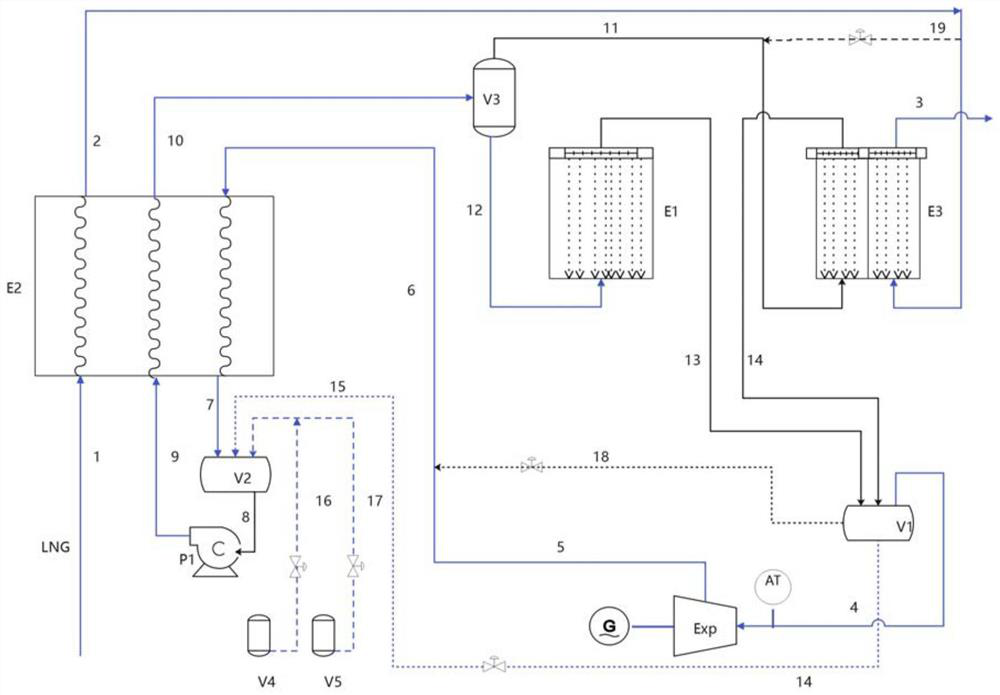

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and this embodiment. The described specific embodiments are only used to explain the present invention, and are not intended to limit the present invention.

[0017] The LNG cold energy power generation device has the advantages of small number of equipment, large capacity, high integration, high utilization rate of LNG cold energy, high power generation efficiency, reliable equipment, convenient adjustment and strong adaptability. The device includes: Method 1, high-pressure plate fin replacement Heater + coiled tube heat exchanger mode: (1) mixed refrigerant condensing heat exchanger E2, using a high-pressure plate-fin heat exchanger with small heat transfer temperature difference and high efficiency; (2) refrigerant evaporator E1, using a coiled tube heat exchanger Heater with high reliability; low-temperature natural gas reheater E3 adopts coiled tube heat exchanger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com