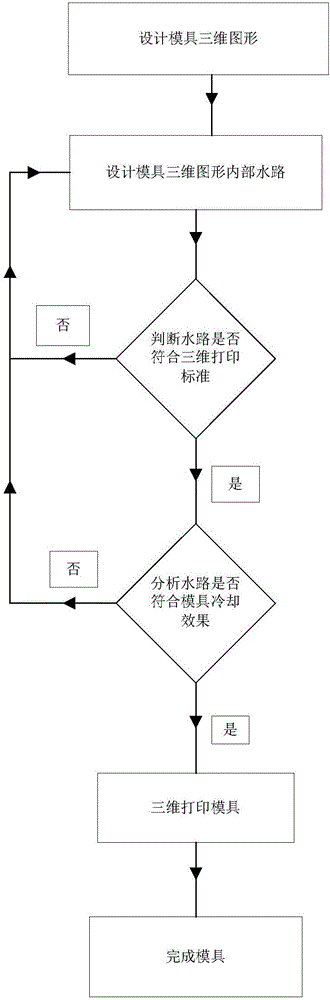

Mold manufacturing method based on three-dimensional printing

A technology of three-dimensional printing and mold manufacturing, which is applied in the field of mold manufacturing, can solve the problems of long processing cycle, complicated process, poor cooling effect of mold waterway, etc., and achieve the effect of reducing processing risk and shortening processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. According to the overall shape of the mold, select the number, shape and size of the mold waterways.

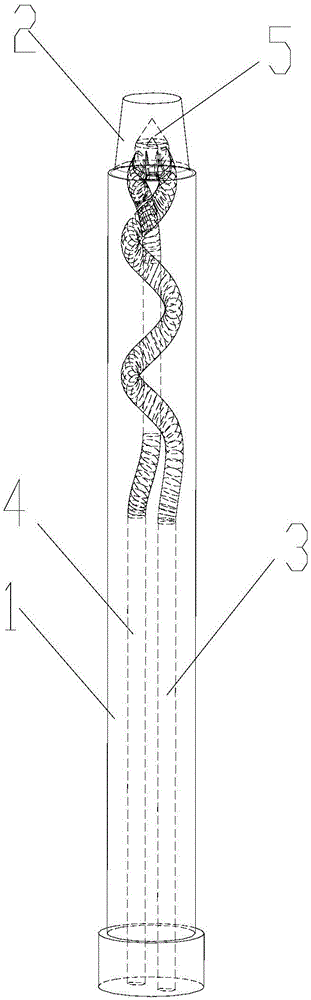

[0034] Such as figure 2 As shown, the shape of the mold is basically a cylinder, the lower end is a uniform cylinder 1 with a middle diameter of 20 mm; the upper end is a circular frustum 2 with a diameter of the upper end circle of 13 mm.

[0035] The mold has only one water inlet and one water outlet, and one waterway fully meets the cooling requirements and flow rate, so the number of waterways is selected as one.

[0036] According to the shape of the mould, the cross-sectional shape of the lower water inlet channel 3 and the outlet water channel 4 is selected as a circle with a diameter of 4 mm. Wherein the water inlet waterway 3 is a spiral rising type, and its purpose is to play cooling effect to the greatest extent, and the water outlet waterway 4 descends along the center, avoids the water inlet waterway 3, and leads to the water outlet waterway 4 through...

Embodiment 2

[0049] 1. According to the overall shape of the mold, select the number, shape and size of the mold waterways.

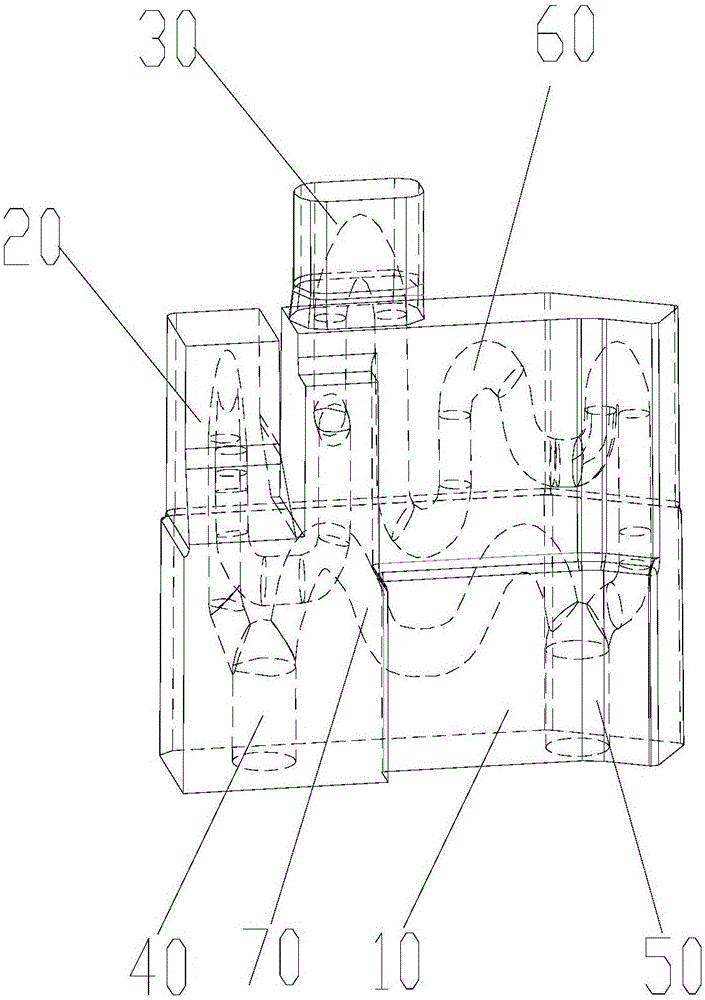

[0050] Such as image 3 As shown, the mold body 10 is a special-shaped structure, and the whole is a deformed cuboid with a length of about 50 mm and a width of about 14 mm; one side has an independent special-shaped boss 20 with a length of about 11 mm and a width of about 9 mm; the top has a waist Shaped boss 30, its length is about 12mm, and width is about 6.5mm; Water inlet 40 and water outlet 50 diameters are 6mm.

[0051] The mold has only one water inlet and one water outlet, and the number of waterways is temporarily selected as one.

[0052] According to the shape of the mould, due to the small size of the special-shaped boss 20 and the waist-shaped boss 30, the cross-sectional shape of the first waterway 60 is conventionally selected as a circle with a diameter of 3mm; since the flow rate of the first waterway 60 is obviously smaller than that of the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com