Cage terminal wire remover

A terminal and cage-type technology, which is applied in the field of cage-type terminal wire withdrawal, can solve problems such as low efficiency and troublesome cage-type terminal wire removal, so as to improve wire removal efficiency, reduce disassembly and wire removal time, and avoid secondary wire removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

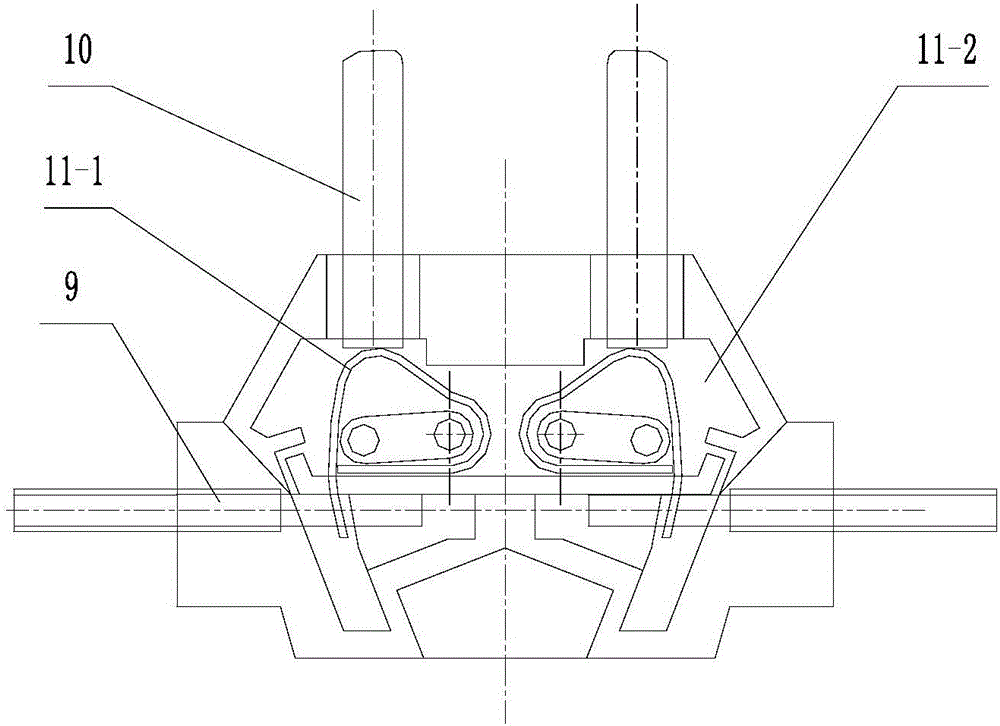

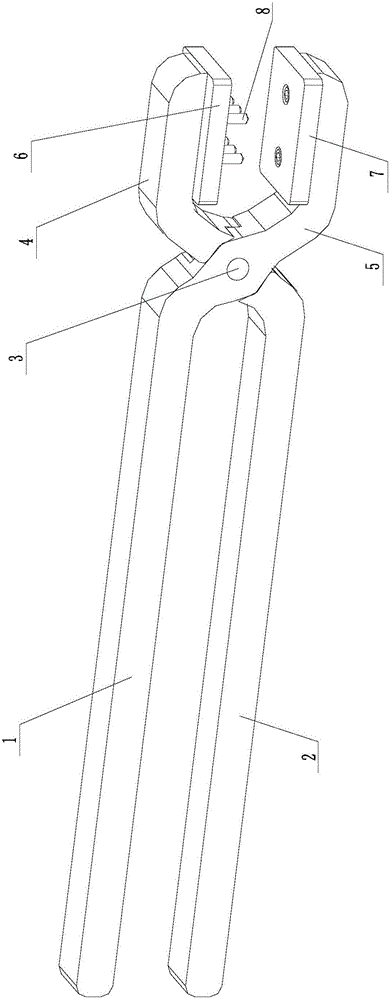

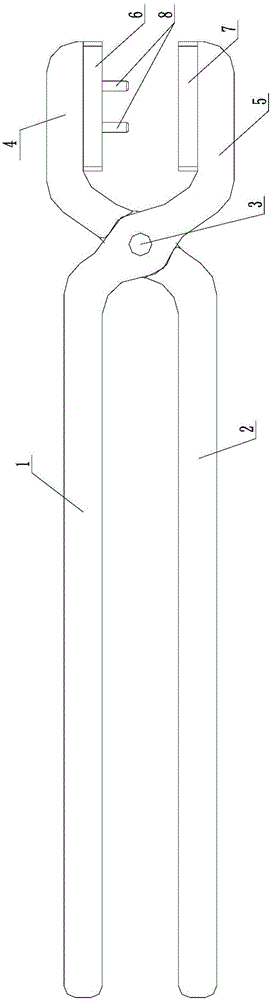

[0014] Such as Figure 2 to Figure 5 As shown, the cage terminal wire remover of the present invention includes a fixed handle 1, a movable handle 2, a rotating shaft 3, a movable jaw 4, a fixed jaw 5, an upper pad 6, a lower pad 7 and eight needle points that are conical The thimble 8; the movable handle 2 is rotationally connected with the fixed handle 1 through the rotating shaft 3, the movable jaw 4 is fixed on the front end of the movable handle 2, the fixed jaw 5 is fixed on the front end of the fixed handle 1, and the upper block 6 is fixed on the movable handle by screws. On the inner side of the jaw 4, the lower block 7 is fixed on the inner side of the fixed jaw 5 by screws; eight thimbles 8 are divided into two rows along the longitudinal direction of the rotating shaft 3 and fixed on the upper block 6, and the two rows of thimbles 8 are fixed alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com