A multi-core cable automatic line management and branching device and its working method

A technology for multi-core cables and branching devices, which is used in cable installation devices, cable installation, equipment for dismantling/armored cables, etc. Effective control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Embodiments of the present invention will be described in detail below, and examples of the embodiments are illustrated in the drawings, in which the same or similar reference numerals represent the same or similar elements or elements having the same or similar functions. The following is exemplary, and is intended to be used to illustrate the invention without understanding the limitation of the invention.

[0036]In the description of the present invention, it is to be understood that the term "center", "longitudinal", "lateral", "length", "width", "thickness", "upper", "lower", "front", " orientation or positional relationship rear "," left "," right "," vertical "," horizontal "," top "," bottom "," inner "," clockwise "," counterclockwise "and the like based on the attachment indicated by FIG positional relationship or orientation, for convenience of description only and the present invention is to simplify the description, but does not indicate or imply that the devi...

Embodiment 2

[0048] The embodiment according to the present embodiment, a multi-core cable management working method of the automatic line of the divider means, the specific work methods are as follows: 1): the wire is placed on the first jaw 103 fixed position, and to ensure peeling of root red and yellow two lines immediately above the position, and then start the device;

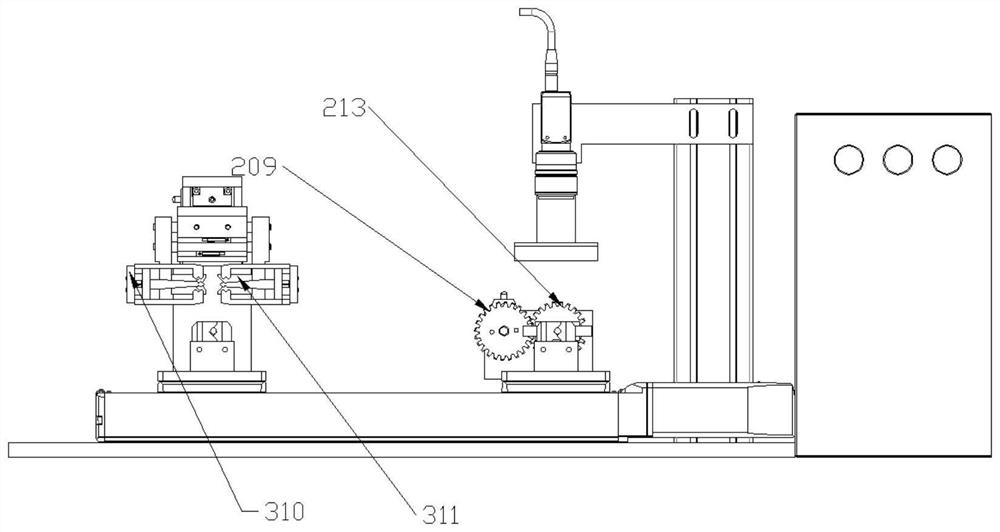

[0049] 2): slider cylinder 212 to drive the entire module is moved forward, the cylinder 207 drives the second jaw 208 are self-closing wire clamping head;

[0050] 3): The second jaw 208 to be sandwiched between the wire head, the first work servomotor 211, drives the second jaw 208 as anti-twist wire Figure 4 In b, the pre-stress the release wire; a first servomotor 211 and then reversed, the wire away, with the camera detection, until the wire is completed as far spread Figure 4 Shown in C;

[0051] 4): a second cylinder 207 to drive jaws 208 open, the slide cylinder 212 to drive the entire module is retracted to its o...

Embodiment 3

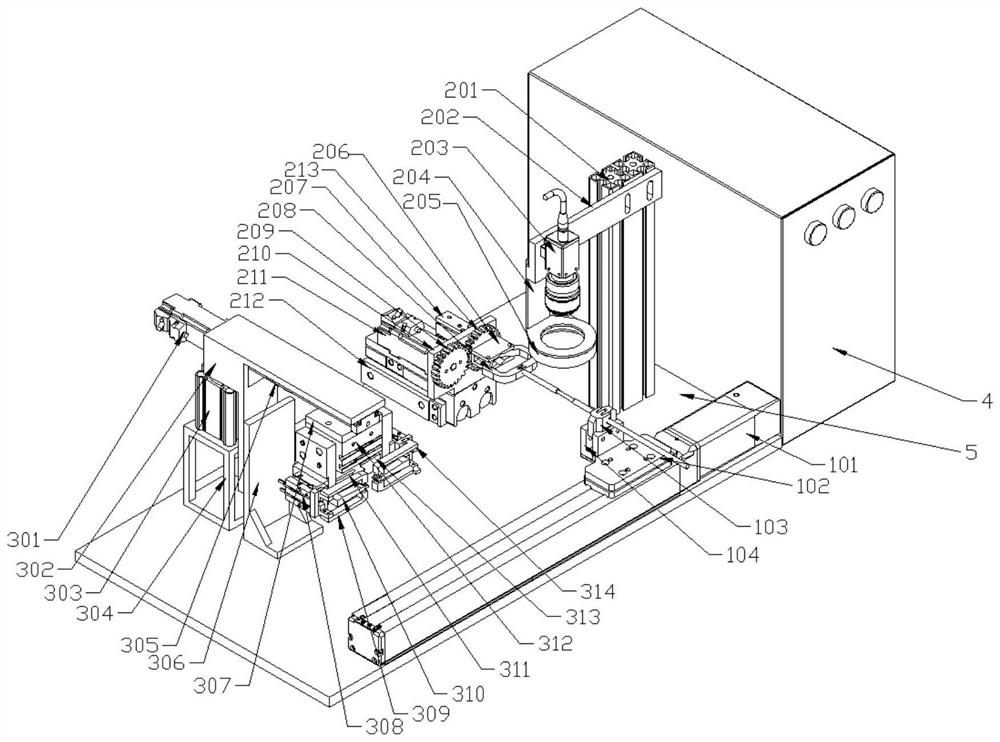

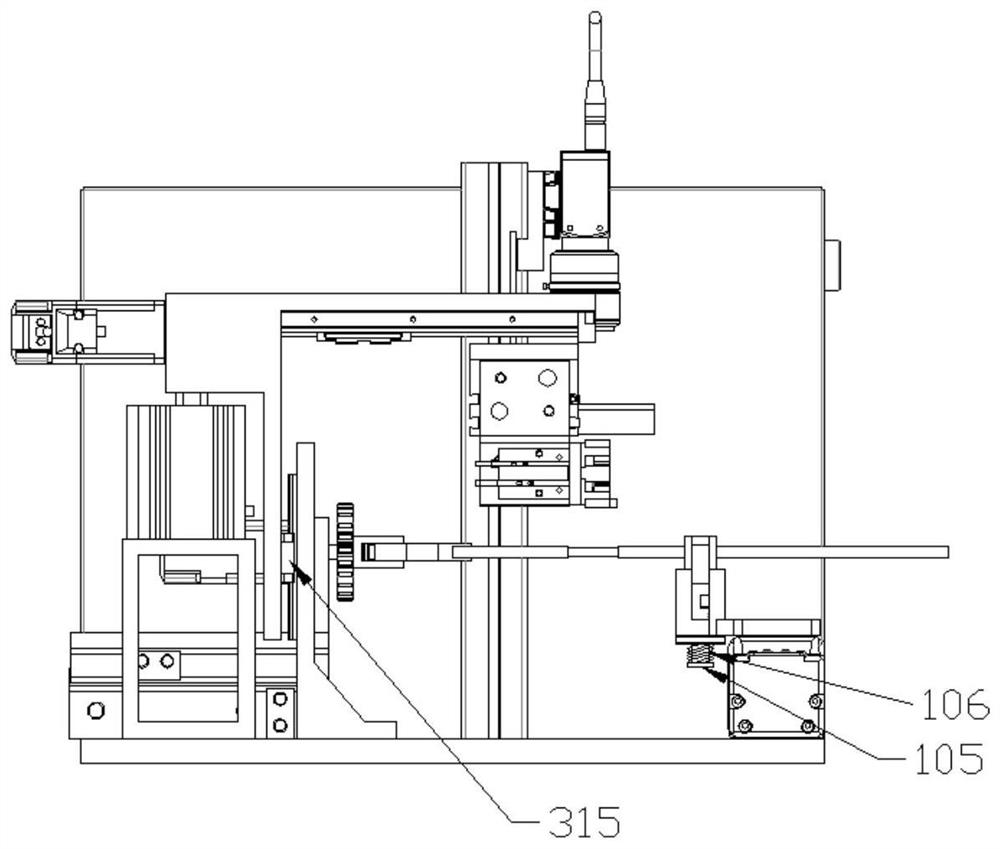

[0062] A multi-core cable shown in FIG automatic splice cable management apparatus comprising: a conveyance mechanism 1, the color detecting means 2, 3 sub-line mechanism, electronic control part 4 and the fixing plate 5, the conveying means 1, a color detection means 2, the sub-line mechanism 3 are provided on the fixing plate 5, the electrically controlled section 4 is provided on one side of the fixed plate 5, and the conveyance means 1, detection means 2 and the color sub-line and electronic control means 3 are part 4 is connected.

[0063]In the present embodiment, the conveyance mechanism 1 provided with an electric cylinder 101, the mount 102, first jaw 103, the support base 104, spring 106 and pin 105, the electric cylinder 101 is provided on the fixing plate 5, and an output terminal is provided with the slide table, the mount stage 102 provided in the slide, the first jaw 103 and the support 102 provided in the intermediate base mount 104, and rotates about the axis, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com