Ni base alloy flux cored wire

A technology of flux-cored welding wire and base alloy, applied in welding medium, welding equipment, metal processing equipment, etc., to achieve the effect of improved viscosity, excellent weld bead shape, and uniform slag coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

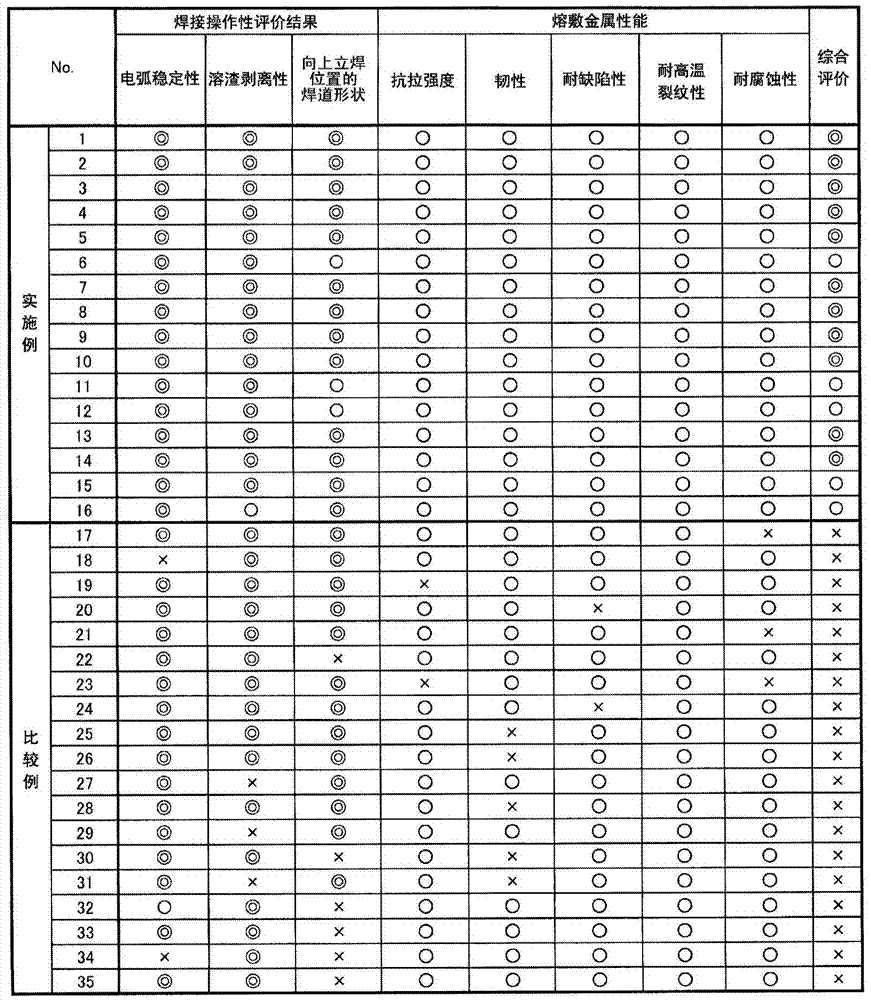

Examples

Embodiment Construction

[0036] Hereinafter, the embodiment of the present invention will be described in detail.

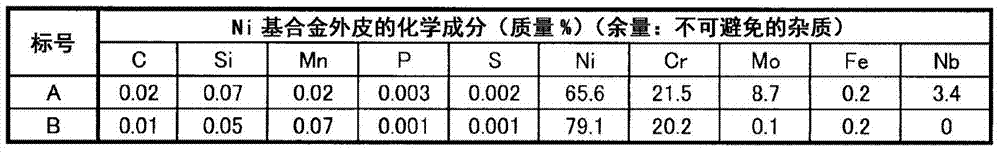

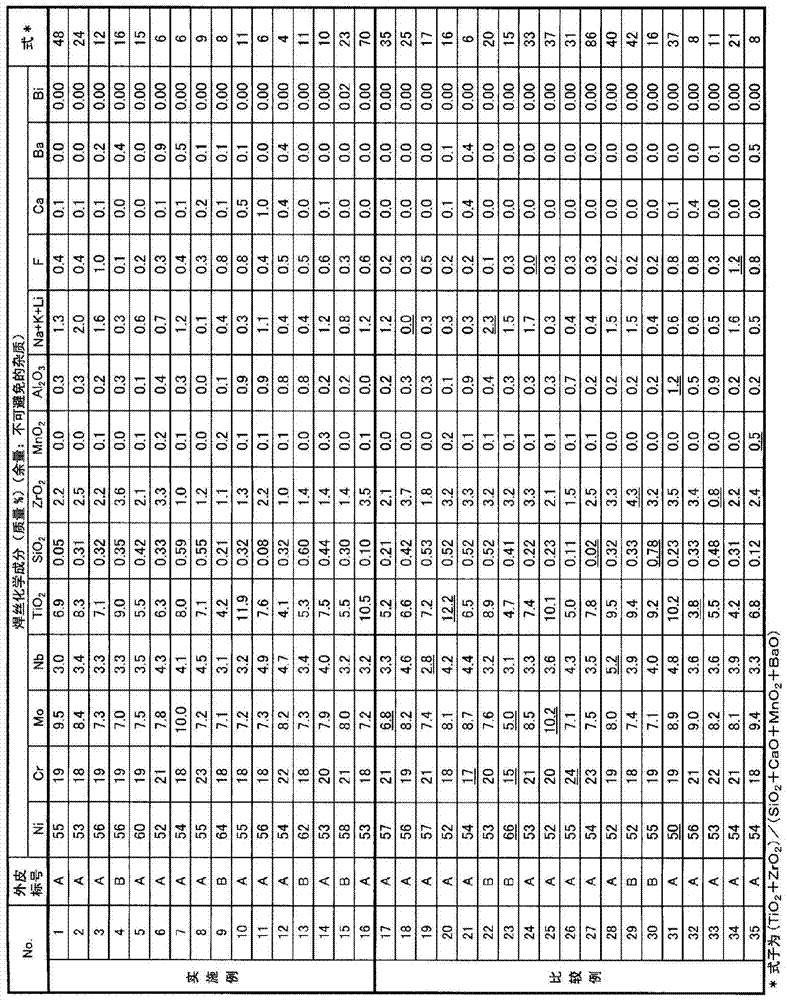

[0037] The flux-cored welding wire of the present invention is a Ni-based alloy flux-cored welding wire in which the sheath of the Ni-based alloy is filled with flux. Furthermore, the flux-cored wire contains Ni, Cr, Mo, and Nb in specified amounts in the total mass, and the flux contains TiO in specified amounts based on the total mass of the welding wire. 2 , SiO 2 , ZrO 2 , MnO 2 、Al 2 o 3 , and the flux contains alkali metal compounds of Na, K, and Li in predetermined amounts in terms of alkali metals based on the total mass of the welding wire, and fluorides in predetermined amounts in terms of fluorine.

[0038] Hereinafter, the reasons for limiting the components of the flux-cored wire will be described.

[0039]

[0040] Ni is added to stabilize the austenite structure. When the Ni content is less than 52% by mass, the content of other elements increases relatively, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com