Vertical centrifugal mill

A vertical centrifuge and mill technology, applied in grain processing, etc., to achieve the effects of stable operation, uniform feeding, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

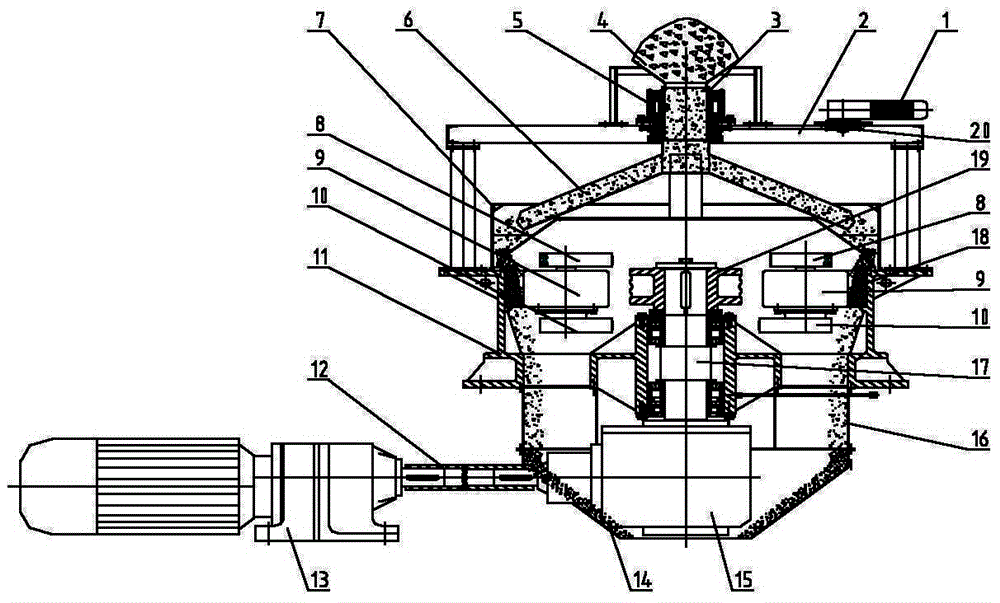

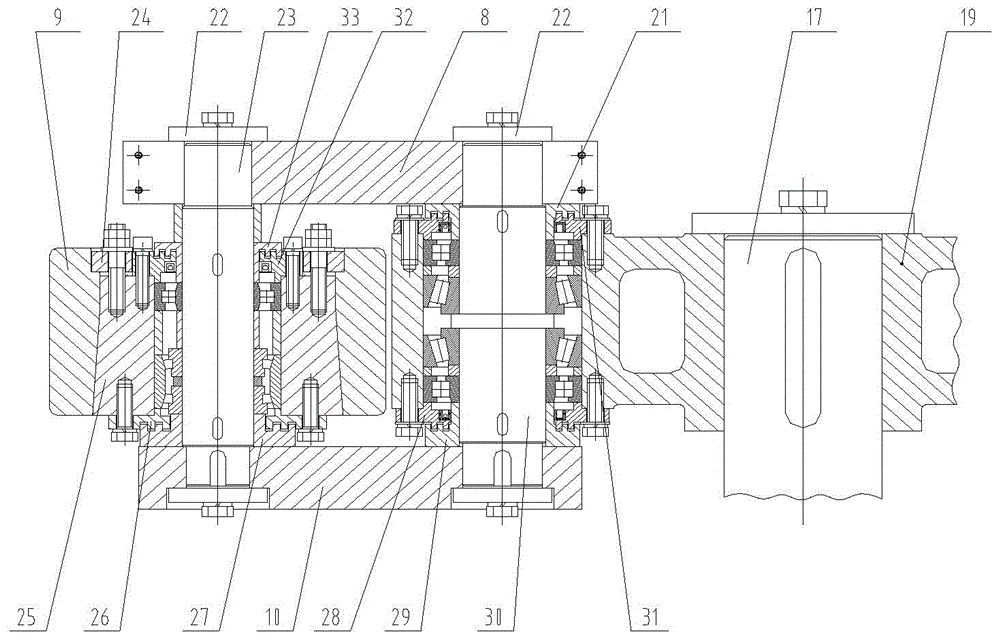

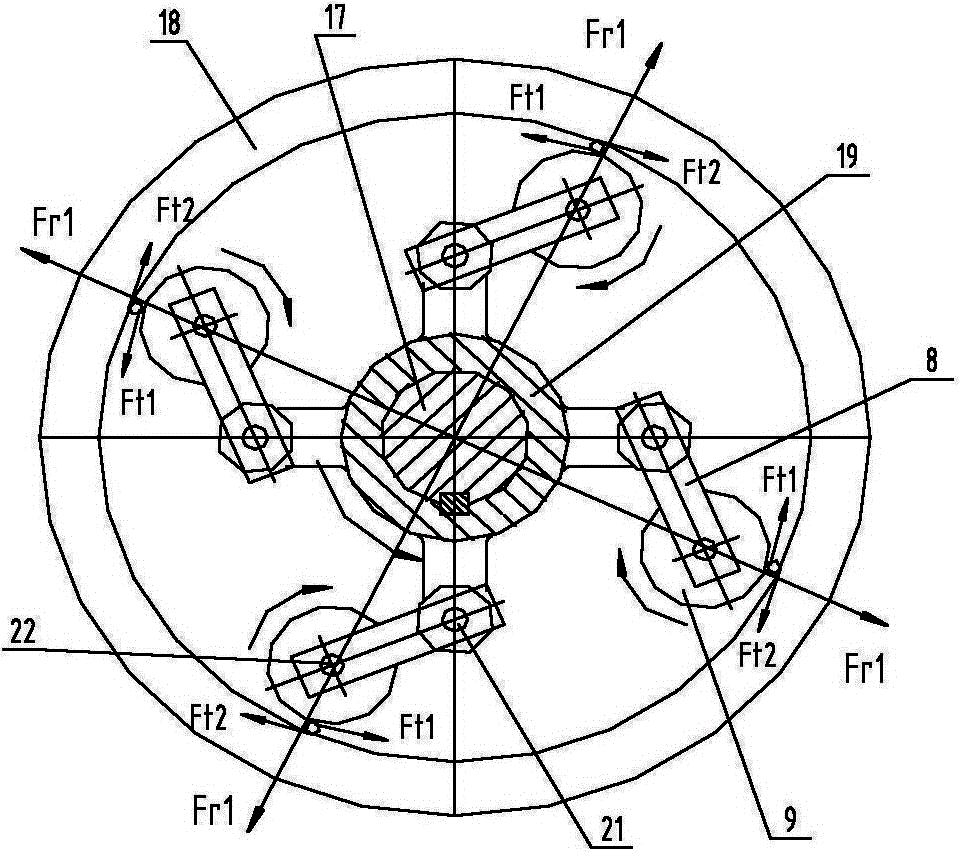

[0035] Such as figure 1 As shown, the central hole of the cylinder body 11 is equipped with a main shaft 17, and the lower part of the main shaft 17 is equipped with a commutator 15, and the commutator 15 is connected with the reduction motor 13 through a universal coupling 12. The geared motor 13 can be adjusted by frequency conversion to drive the main shaft 17, the star bracket 19 and the roller 9 to rotate at high speed. The star bracket 19 is coupled with the main shaft 17 through a key. The conical lower hopper 14 is connected with the cylinder body 11 through the lower material cylinder 16 . The grinding ring 18 is installed in the stepped hole of the cylinder body 11 , its outer circle is in clearance fit with the cylinder body 11 , and a positioning block is installed on its circumference to prevent the grinding ring 18 from rotating in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com