Quick adjustment technology for gaps between grinding rollers of coal mill and liner plate of grinding bowl

A rapid adjustment, coal mill technology, applied in the direction of grain processing, etc., can solve the problems of the continuous work of the milling system, the adverse effects of economic benefits, and the decline of coal powder grinding efficiency, so as to improve the continuous workability and shorten the maintenance time , the effect of high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

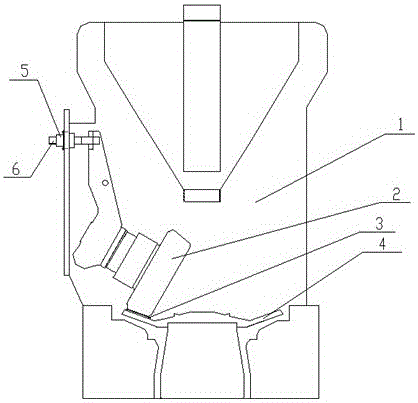

[0021] The present invention uses a plate to limit the gap between the grinding roller 2 and the bowl liner 4 of the HP bowl coal mill. When the grinding roller 2 falls, it only needs to rub against the plate and have a slight twitching resistance, so as to realize the rapid adjustment of the grinding roller 2 and the purpose of grinding bowl liner 4 clearance. Because the grinding bowl has a conical surface, when the plate is twitched to be pressed by the grinding roller, the hand-held part must have a certain deformation. Therefore, the plate used must have certain physical deformation characteristics, such as: asbestos plate, plastic plate, nylon plate, etc. The asbestos board 3 has the advantages of convenient material acquisition, low price, and certain physical deformation characteristics.

[0022] Concrete steps of the present invention are as follows:

[0023] a. Coal mill 1 stops coal supply, closes the hot air shut-off valve, passes cold air into coal mill 1, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com