Preparation method of konjac particles and application thereof to meal replacement powder

A technology of granulated konjac and konjac flour, applied in the directions of food preparation, application, food science, etc., can solve the problems of excessive swelling, unevenness, easy agglomeration and subsistence, etc. effect of taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

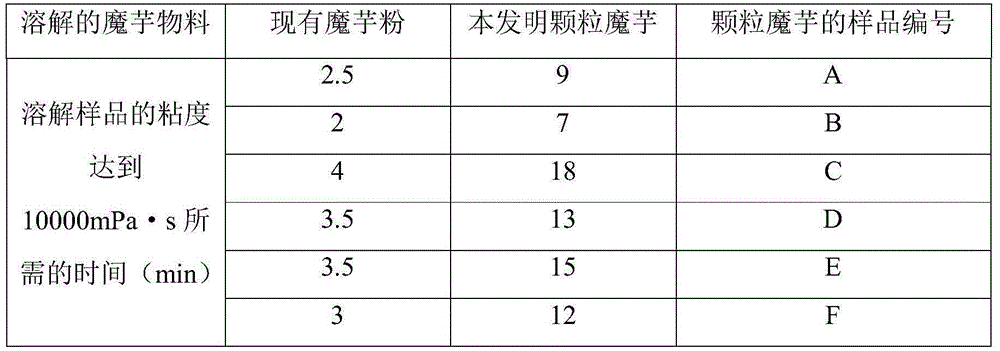

Examples

Embodiment 1

[0024] Add 20Kg of konjac powder into the cyclone mixer, stir the raw material of konjac powder, and stir in a high-speed cyclone until the konjac powder in the hopper of the mixer is emptied, that is, the konjac powder is fully crushed and mixed evenly; keep the konjac powder in the state of continuous stirring, press 0.1L / Add water in the proportion of Kg, that is, add 2L of water, and continue to stir until the mixture is uniform, and the material continues to expand during the stirring and mixing process; stop stirring, and let it stand for 2 minutes to make the mixed material moderately swell into a fluffy body; the volume of the fluffy body is not large. After shrinking again, take out the fluffy body quickly and spread it evenly; dry at 40°C for 1 hour to achieve the purpose of removing moisture, and dry until the moisture content in the fluffy body is lower than 7wt%; the fluffy body becomes a block after drying shape, a slight touch will make it broken into particles;...

Embodiment 2

[0027] Add 25Kg of konjac powder into the cyclone mixer, stir and crush the konjac powder raw material, high-speed cyclone stirring until the konjac powder in the hopper of the mixer is emptied, that is, the konjac powder is fully crushed and mixed evenly; keep the konjac powder in the state of continuous stirring, press 1L / Kg Add water in the ratio of 25L, that is, add 25L of water, and continue to stir until the mixture is uniform, and the material continues to expand during the stirring and mixing process; stop stirring, and let it stand for 14 minutes, so that the mixed material moderately swells into a fluffy body; the volume of the fluffy body no longer After shrinking, take out the fluffy body quickly and spread it evenly; dry it at 65°C for 3 hours to achieve the purpose of removing moisture, and dry until the moisture content in the fluffy body is lower than 7wt%; the fluffy body becomes a block after drying , a slight touch will make it broken into particles; take out...

Embodiment 3

[0030] Add 30Kg of konjac powder into the cyclone mixer, stir and crush the konjac powder raw material, high-speed cyclone stirring until the konjac powder in the hopper of the mixer is empty, that is, the konjac powder is fully crushed and mixed evenly; keep the konjac powder in the state of continuous stirring, press 2L / Kg Add water in the ratio of 60L water, and continue to stir until the mixture is uniform, and the material continues to expand during the stirring and mixing process; stop stirring, and let it stand for 30 minutes, so that the mixed material moderately swells into a fluffy body; the volume of the fluffy body no longer After shrinking, take out the fluffy body quickly and spread it evenly; dry at 90°C for 5 hours to achieve the purpose of removing moisture, and dry until the moisture content in the fluffy body is lower than 7wt%; the fluffy body becomes a block after drying , a slight touch will make it broken into particles; take out the block material, put i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com