Manufacturing process of convenient vermicelli

A production process and a technology for vermicelli, applied in the field of production technology of instant vermicelli, can solve the problems of inability to satisfy the instant potato flour, long rehydration time of the instant vermicelli, and inability to satisfy consumers, etc., and achieves shortened rehydration time, good fresh-keeping effect, vermicelli translucent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

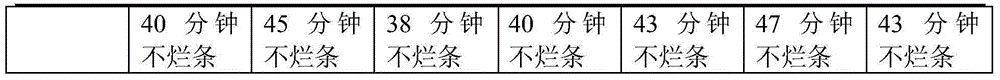

Examples

Embodiment 1

[0025] A. Raw material preparation: Prepare sweet potato starch, salt, emulsified oil, konjac flour, glycerin, citric acid with a mass ratio of 20:0.1:0.04:0.04:0.4:0.01, divide the prepared sweet potato starch in a ratio of 1:25 It is sweet potato starch a and sweet potato starch b, for later use;

[0026] B. Thickening: mix the sweet potato starch a in step A with water in a ratio of 4:3 by weight to obtain a mixture, then mix the mixture with water in a ratio of 7:15 to obtain a mixed slurry for subsequent use;

[0027] C, pulping: put the mixed slurry obtained in step B in a pulping machine, stir for 2 minutes, then add sweet potato starch b prepared in step A, salt, emulsified oil, konjac powder, glycerin, lemon to the mixed slurry after stirring acid, stirred for 5min to obtain a mixed slurry, then the mixed slurry was mixed with water in a ratio of 40:1 by weight, stirred for 10min, and then the pH value of the mixed slurry was adjusted to 3.7-3.8 with citric acid to ob...

Embodiment 2

[0034] A. Raw material preparation: Prepare sweet potato starch, salt, emulsified oil, konjac powder, glycerin, citric acid with a mass ratio of 19:0.08:0.03:0.05:0.5:0.009, and prepare sweet potato starch according to 1:23 sweet potato starch a , sweet potato starch b, set aside;

[0035] B. Thickening: mix the sweet potato starch a in step A with water at a ratio of 1.1:1 by weight to obtain a mixture, then mix the mixture with water at a ratio of 6:16 to obtain a mixed slurry for subsequent use;

[0036] C, pulping: put the mixed slurry obtained in step B in a pulping machine, stir for 3 minutes, then add sweet potato starch b prepared in step A, salt, emulsified oil, konjac powder, glycerin, lemon to the mixed slurry after stirring acid, stirred for 4min to obtain a mixed slurry, then the mixed slurry was mixed with water in a ratio of 41:1 by weight, stirred for 11min, then the pH value of the mixed slurry was adjusted to 3.7 with citric acid, and a good pH value was obta...

Embodiment 3

[0043] A. Raw material preparation: Prepare sweet potato starch, salt, emulsified oil, konjac powder, glycerin, citric acid with a mass ratio of 21:0.09:0.05:0.02:0.6:0.011, and prepare sweet potato starch according to 1:27 sweet potato starch a , sweet potato starch b, set aside;

[0044] B. Thickening: mix the sweet potato starch a in step A with water at a weight ratio of 1.4:1 to obtain a mixture, then mix the mixture with water at a ratio of 7.2:14 to obtain a mixed slurry for subsequent use;

[0045] C, pulping: put the mixed slurry obtained in step B in a pulping machine, stir for 1min, then add sweet potato starch b prepared in step A, salt, emulsified oil, konjac powder, glycerin, lemon to the mixed slurry after stirring acid, stirred for 6min to obtain a mixed slurry, then the mixed slurry was mixed with water in a ratio of 42:1 by weight, stirred for 12min, then the pH value of the mixed slurry was adjusted to 3.8 with citric acid, and a good pH value was obtained. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com