Method for milk cold storage by milk storage quick-cooling machine

A quick cooling machine and milk technology, applied in the direction of milk preservation, dairy products, applications, etc., can solve the problems of internal milk refrigeration, inconvenient transfer, no cold storage structure and heat preservation structure, etc., achieve long-lasting storage and freshness, and prolong downtime , to avoid the effect of cooling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

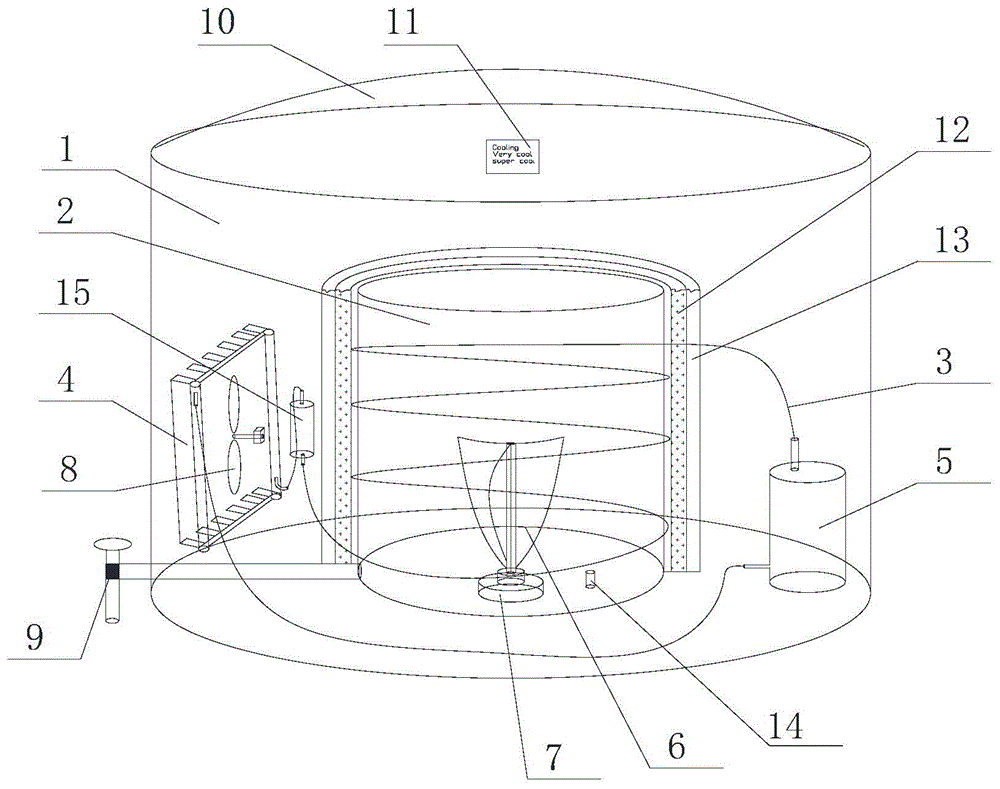

[0034] Such as figure 1 As shown, a method for cold storage of milk by a milk storage quick-cooler according to the present invention. After the milk is squeezed out, it is put into the cavity of the milk storage quick-cooler for holding milk, and the milk is first refrigerated to cool the milk until it is suitable for storage. The temperature is conducive to maintaining the quality of fresh milk, and then the milk storage quick cooler is transported to the milk processing site together with the milk. The transportation process is: the milk storage quick cooler is powered off, the cold storage structure of the milk storage quick cooler and The heat preservation structure keeps the milk warm, and the milk storage quick cooler is transported together with the milk to the milk processing site; after the milk is poured out, the milk storage quick cooler is brought back to the pasture for reuse, especially suitable for nomadic production. Moreover, the volume of the milk storage qu...

Embodiment 2

[0042] The above-mentioned refrigeration can also be rapid cooling, that is, to quickly cool the milk to a suitable storage temperature, which is conducive to maintaining the quality of fresh milk. The rapid cooling process is: power on and start the milk storage quick cooler, the refrigeration structure starts to refrigerate, and the stirring structure starts to cool the milk. Stir, the milk is in a flowing state in the milk storage quick cooler, and the temperature of the milk is quickly cooled to the suitable storage temperature of the milk; if the internal milk is in a static state, it will take 10 hours or longer to put the milk at 38°C Cooling to 6°C, and the temperature of the milk is very uneven. The closer to the cavity wall, the lower the temperature, and the farther away from the cavity wall, the higher the temperature. The cooling efficiency is obviously not enough, but if the milk is continuously cooled at a low speed Stirring, because the molecular flow of the liq...

Embodiment 3

[0045] like figure 2 As shown, the quick-cooler for milk storage in the present invention includes a shell 1, and an inner tank 2 is arranged in the outer shell 1, and the inner tank is the cavity for holding milk as mentioned above, and the outer wall of the inner tank 2 is provided with a cooling structure. A cold storage structure and a thermal insulation structure are also provided between the shell 1 and the inner tank 2, and a stirring structure capable of stirring the flow of milk inside is also provided inside or outside the inner tank. The liner 1 is made of aluminum alloy material, which can achieve ideal heat transfer efficiency, relatively low cost, easy to shape and process, and has a low density, which can reduce the weight of the milk storage quick-cooler and is easy to move.

[0046] The upper part of the milk storage quick cooler is provided with an integral upper cover structure, the size of the upper cover 10 corresponds to the cross-sectional size of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com