Valve control device and valve control method

A valve control and control deviation technology, applied in the direction of flow control, electrical control, computer control, etc., can solve the problems of the deterioration of the valve opening to the target, the controllability of the cooling water flow adjustment, etc., to improve the settability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

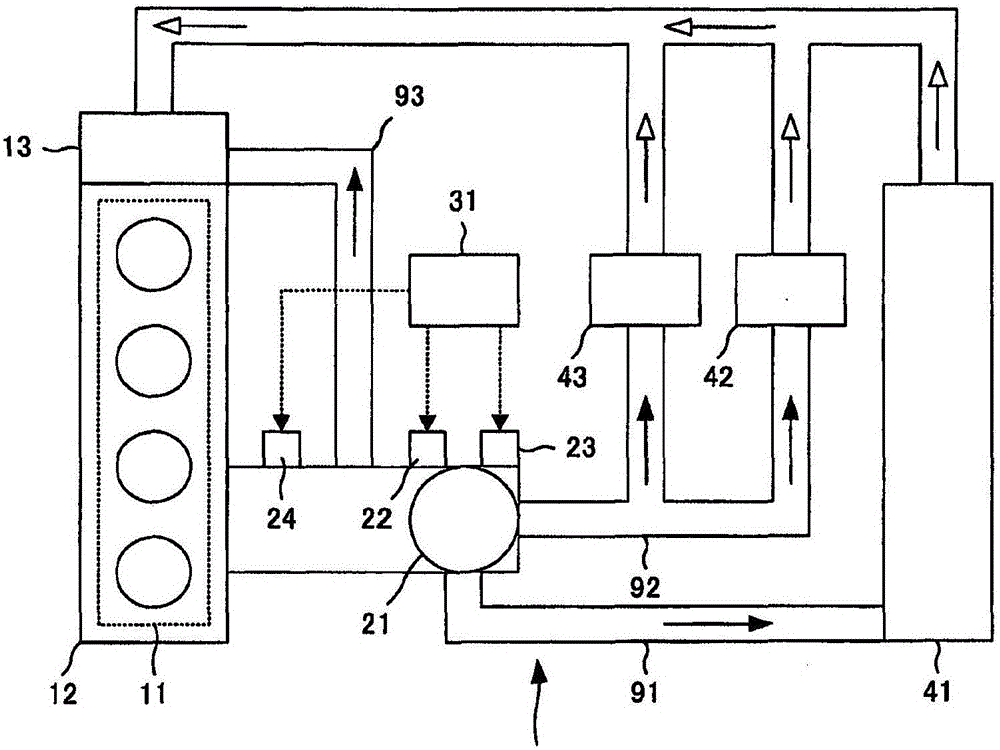

[0021] First, the engine cooling system of this embodiment will be described. figure 1 It is a schematic diagram showing the engine cooling system of this embodiment.

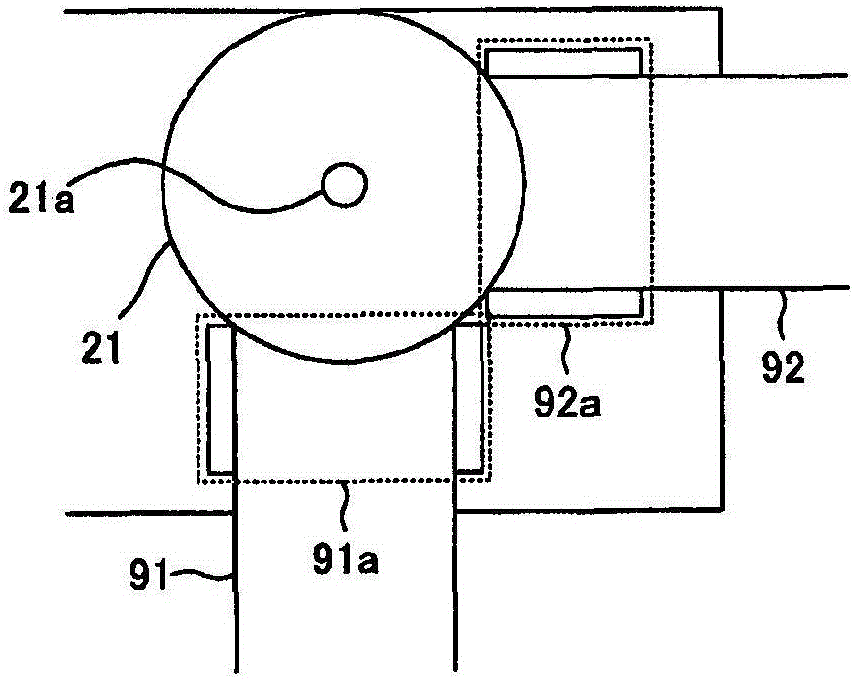

[0022] Such as figure 1 As shown, the engine cooling system 1 of this embodiment includes an engine 11, a water cooling jacket 12, a water pump 13, a cooling water valve 21, a motor 22, a position sensor 23, a water temperature sensor 24, an ECU (Engine Control Unit) 31, a radiator 41, a heater 42. Restrictor 43, main flow conduit 91, sub flow conduit 92, bypass flow conduit 93.

[0023] The engine cooling system 1 circulates cooling water through the main flow conduit 91 , the sub-flow conduit 92 , or the bypass flow conduit 93 , and controls the temperature of the engine 11 through the water cooling jacket 12 .

[0024] The engine 11 is an internal combustion engine of a vehicle such as an automobil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com