A phase shifter with a built-in transmission rod

A transmission rod and phase shifter technology, which is applied to waveguide-type devices, electrical components, circuits, etc., can solve the problems of increasing assembly difficulty, increasing the difference in the displayed value of the down-tilt angle scale, and increasing the cost, so as to optimize the down-tilt angle. Accuracy, the effect of reducing potential intermodulation points, and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0058] A specific implementation of a phase shifter with a built-in transmission rod according to an embodiment is as follows:

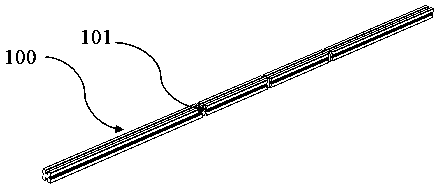

[0059] Such as Picture 9 As shown, the phase shifter includes four dielectric sheets 300, two PCBs 400, and a built-in transmission rod 100;

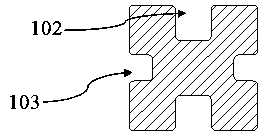

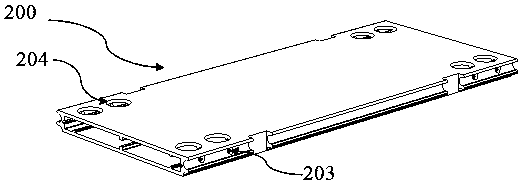

[0060] The built-in transmission rod 100 is located in the middle of the cavity 201 of the phase shifter, the four dielectric sheets 300 and the two PCBs 400 are respectively located on both sides of the built-in transmission rod 100, and each PCB 400 is sandwiched between two Between a piece of media 300. Specifically, two PCBs 400, four dielectric sheets 300, and a built-in transmission rod 100 are pushed in along the first limiting protrusion structure 205 in the phase shifter cavity 200 and the rectangular groove 207, and the PCB 400 is welded The disk 403 is directly aligned with the welding process hole 204 on the wall of the phase shifter cavity 200.

[0061] Three buckle structures 302 are provided on one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com