Network filter

A network filter and housing technology, applied in the field of electrical signal transmission, can solve the problems of PIN pin and coil lead wire disconnection, high-voltage processing cost, continuous welding, etc., to save solder, labor and processing costs, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

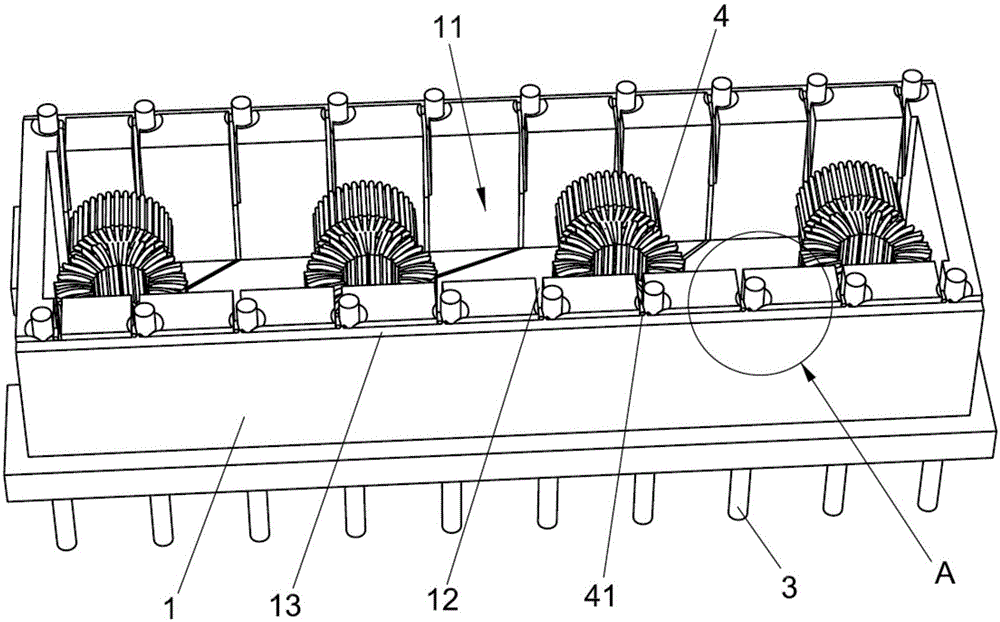

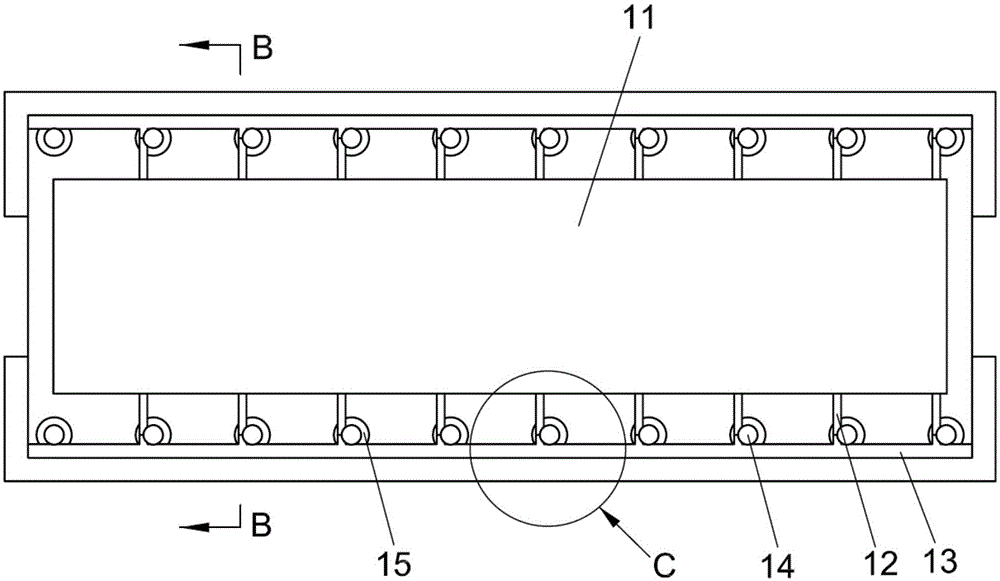

[0022] The present invention provides a network filter, as attached figure 1 As shown, it includes a housing 1 , a PIN needle 3 and an inductance coil 4 . The housing 1 is provided with a groove 11, and the inductance coil 4 is arranged in the groove 11. The housing 1 on both sides of the groove 11 is provided with a clamping groove 12 communicating with the groove 11, and the coil lead wire 41 of the inductance coil 4 is arranged In the wire holding slot 12 , the width of the wire holding slot 12 is larger than the diameter of the coil lead wire 41 . An installation through hole 14 is provided on the edge of the wire clamping slot 12 , the PIN pin 3 is fixedly connected in the installation through hole 14 , and the PIN pin 3 penetrates the housing 1 . The number of PIN needles 3 is the same as the number of coil lead wires 41 .

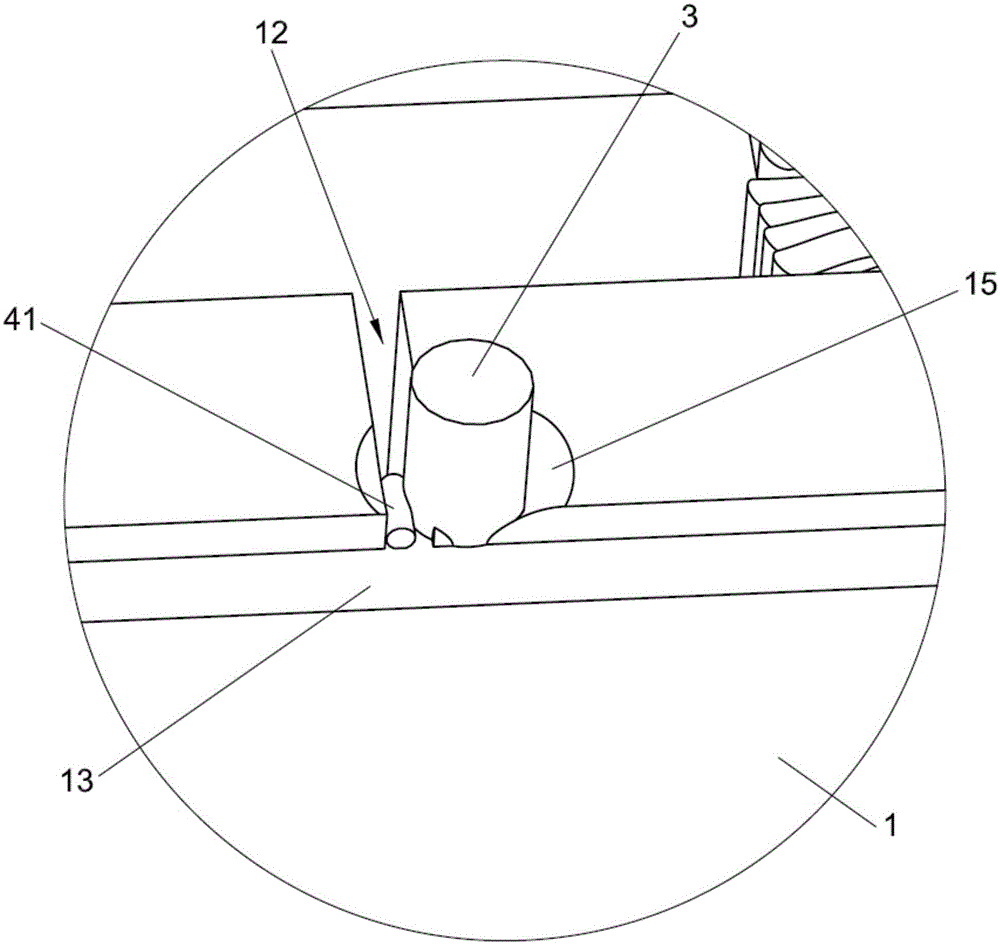

[0023] as attached figure 2 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com