A methane sensor for high-pressure hydrothermal system and its preparation method

A technology of methane sensor and high pressure water, applied in the field of CH4 chemical sensor, can solve the problems of unstable performance and low precision, and achieve the effects of good corrosion resistance, high temperature mechanical strength, strong integrity, and good high temperature insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0024] 1. Composition and production of various parts of the methane sensor.

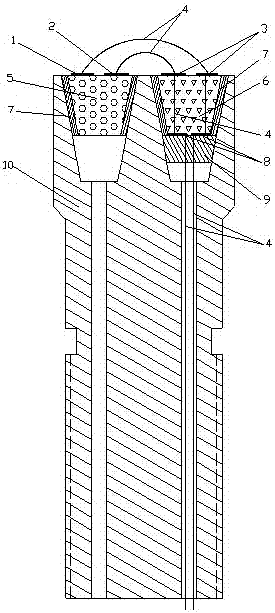

[0025] Such as figure 1As shown, the components of the device in this embodiment are mainly composed of a base 10, a truncated conical high temperature resistant insulating cone pad 9, a high temperature resistant insulating conical sleeve 7, a conical solid electrolyte ceramic 5, a conical truncated high temperature resistant insulating ceramic 6, a spongy It consists of an inert metal layer 3, a sponge-like active electrode 1, a sponge-like inert electrode 2, an inert metal sheet 8, and electrode leads 4. Among them, the base 9 is made of a high-temperature nickel-based alloy, and one end of the nickel-based alloy base 9 has two taper holes, and the other end has two through holes co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com