Hydrogen sensor for high-pressure hydrothermal system and making method thereof

A technology of hydrogen sensor and high-pressure water, applied in the direction of material electrochemical variables, etc., can solve the problems of complex analysis methods, difficult hydrogen in-situ measurement, low working pressure, etc., and achieve improved response rate, increased effective length, and strong sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

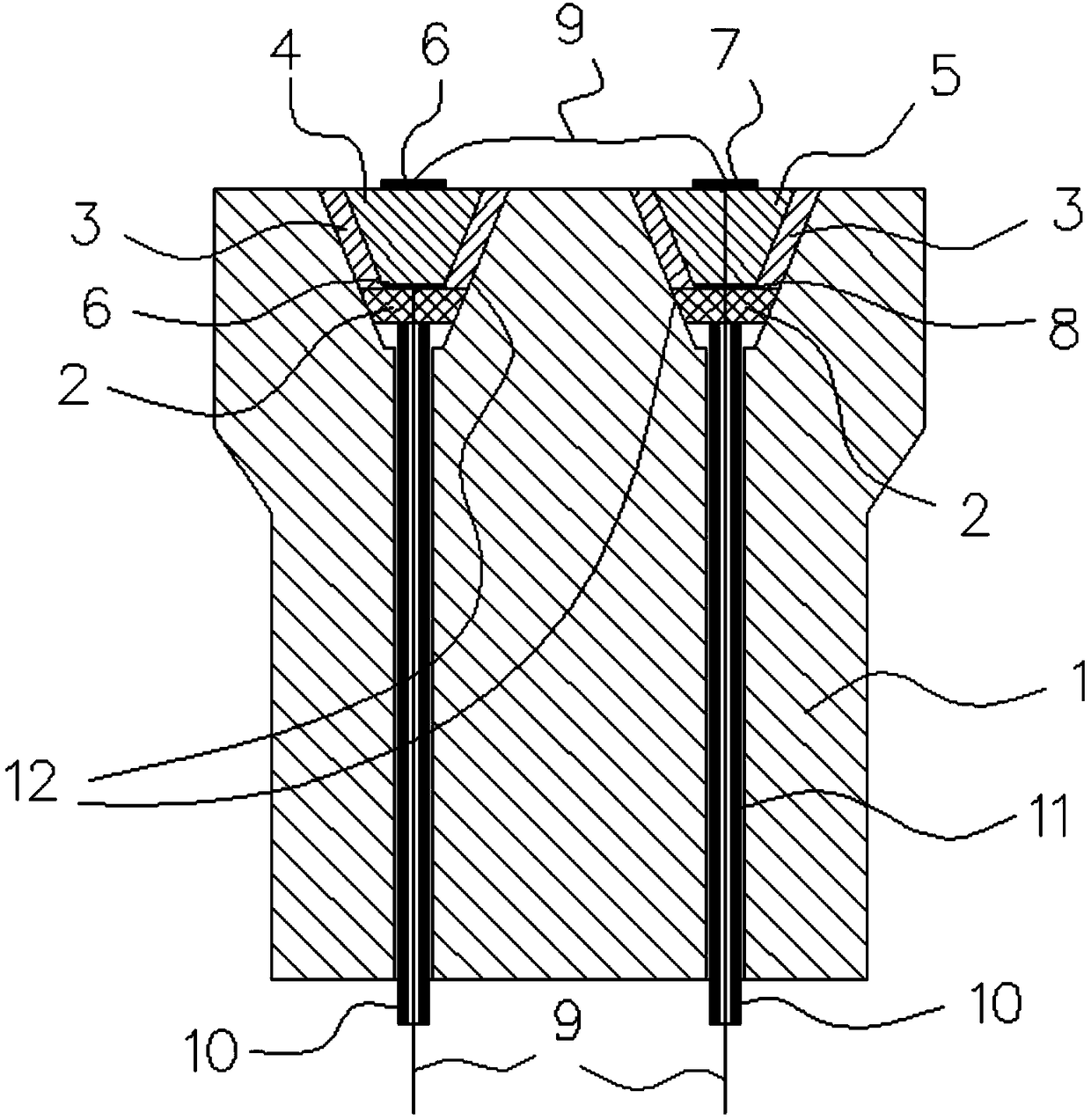

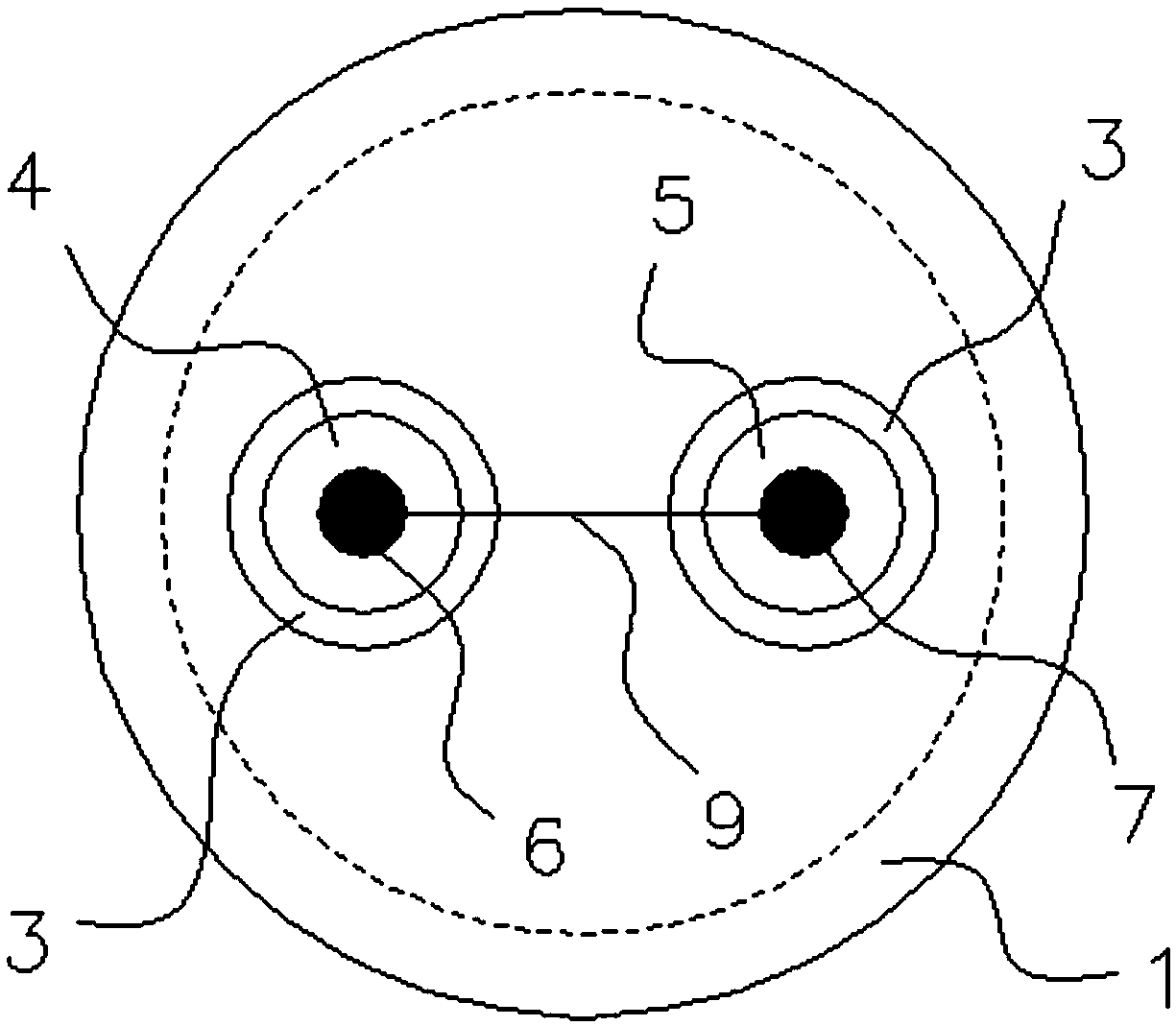

[0049] Embodiment 1: as attached Figure 1~2 As shown, a hydrogen sensor for a high-pressure hydrothermal system, it includes a base 1, a cone pad 2, a cone sleeve 3, an electrolyte ceramic 4 and an insulating ceramic 5, the base 1 is a cylindrical structure, and the base 1 is provided with a parallel symmetrical cylindrical hole 11 and a conical hole 12, the upper, lower, and small bottom ends of the conical hole 12 are connected to the cylindrical hole 11, and a cone pad 2 is provided at the bottom of the conical hole 12, and the conical hole 12 The upper part is provided with a taper sleeve 3, and the taper sleeve 3 is respectively provided with an electrolytic ceramic component and an insulating ceramic component. An insulating tube 10 is provided in the cylindrical hole 11. The insulating tube 10 is in close contact with the cone pad 2. Between the electrolytic ceramic component and the Electrode lead wires 9 are connected between the top surfaces of the insulating cerami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com