Water stop screw rod

A water-stop screw and screw technology, which is applied in the connection of formwork/formwork/work frame, the preparation of building components on site, construction, etc., can solve the problems of increased cost, material waste, and inability to reuse, and achieve saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

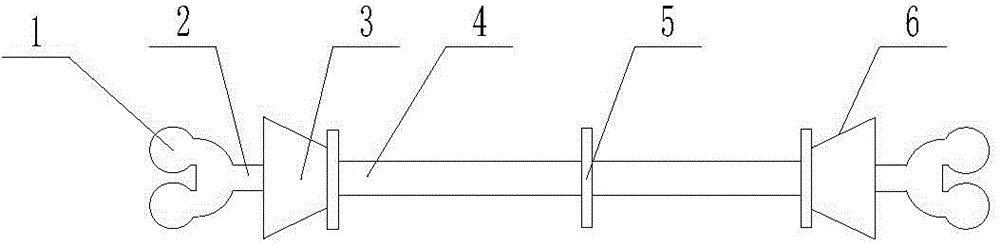

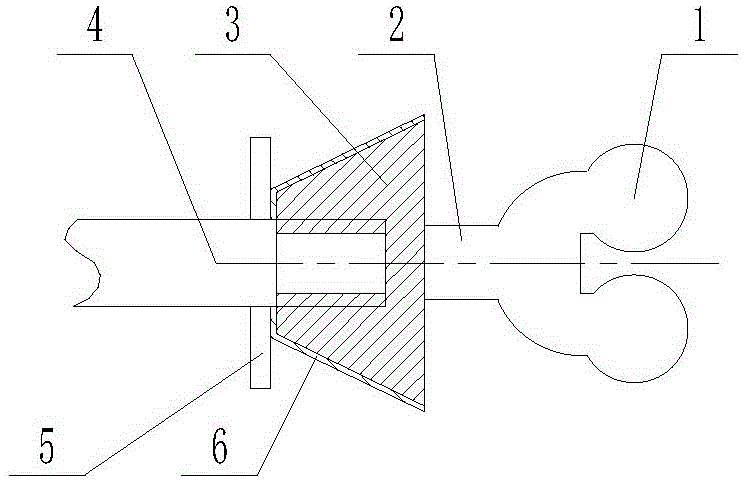

[0013] Such as figure 1 The water-stop screw shown in this embodiment includes a handle 1 , a connecting rod 2 , a pulley 3 , a screw 4 , a water-stop sheet 5 , and a foam layer 6 .

[0014] Such as figure 1 , figure 2 As shown, three water-stop sheets 5 with holes are respectively set on the two ends and the center of the screw 4, and then the water-stop sheets 5 are welded on the screw 4, so that there is no gap between the water-stop sheets 5 and the screw 4, To ensure a better water-stop effect, the two ends of the screw 4 are respectively provided with a sleeve 3 that is threadedly connected with the screw 4. When the sleeve 3 and the thread of the screw 4 are in a connected state, the water-stop sheet 4 fits with one end surface of the sleeve 3, and the connection Rod 2 and pulley 3 are integrally designed, which is convenient t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com