Telescopic Rebar Splice Kit

A telescopic and kit technology, applied in the direction of building components, building reinforcements, structural elements, etc., can solve problems such as unusable connection structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

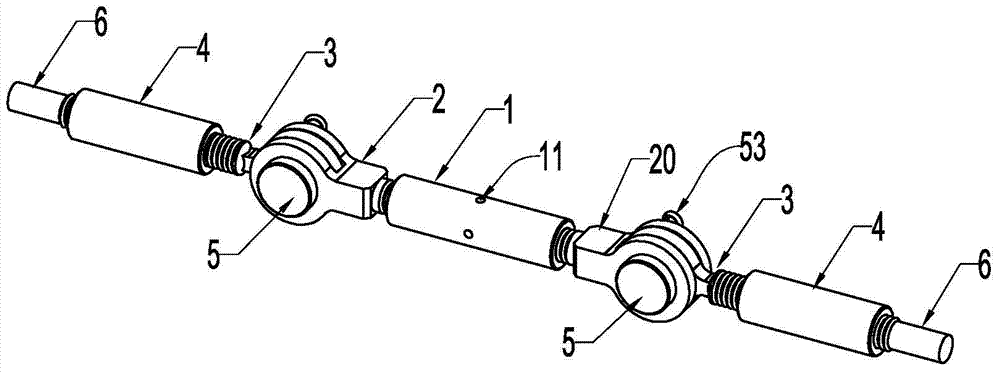

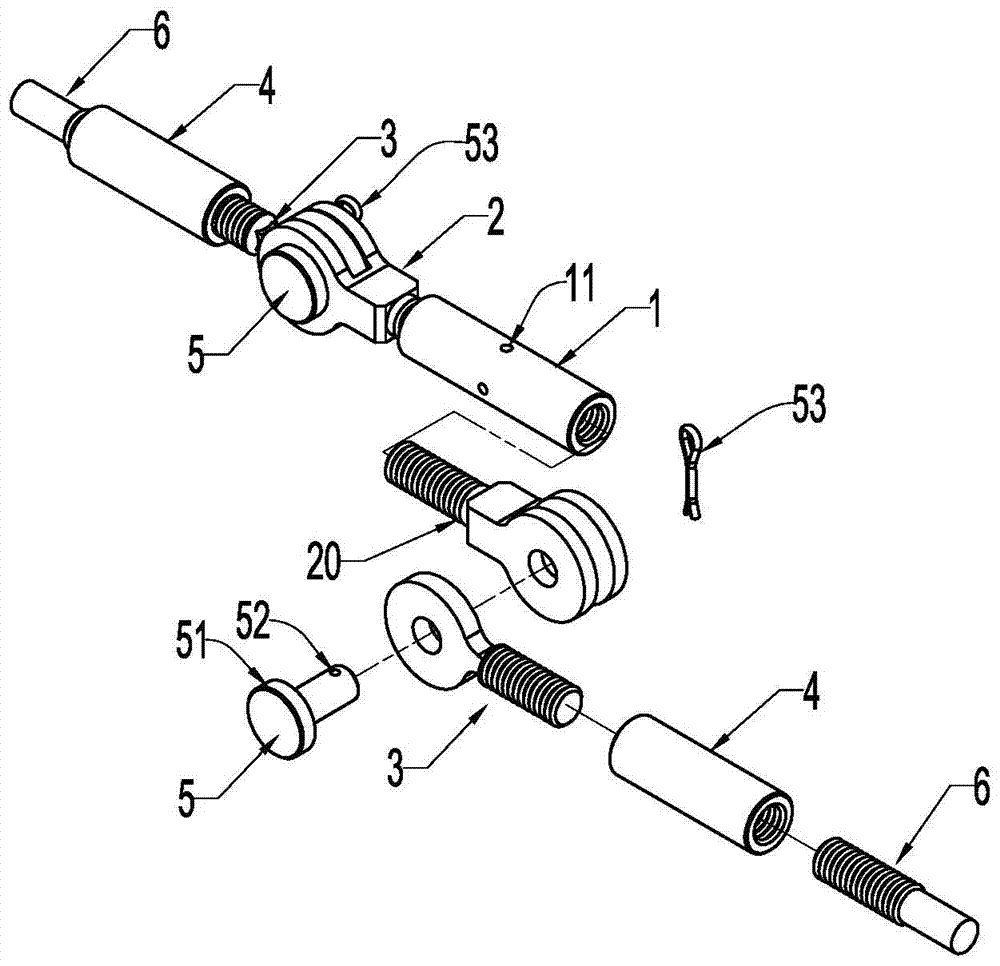

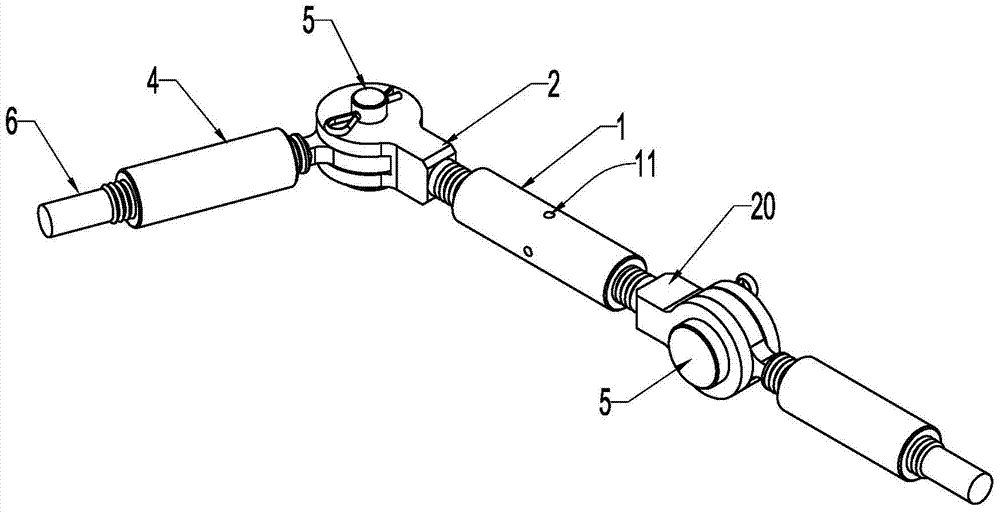

[0024] refer to figure 1 , figure 2 and image 3 , a telescopic steel bar connection kit, the main body of the kit includes a two-way screw sleeve 1, a forward screw seat 2, a reverse screw seat 20, a screw joint 3, a one-way screw sleeve 4 and a pin shaft 5; one end of the two-way screw sleeve 1 The inner thread of the thread is the same as the inner thread of the one-way thread sleeve 4, the thread of the forward screw seat 2, the screw joint 3 and the outer thread of the steel bar head 6 are the same, and the outer thread of the steel bar head 6 is rough-turned on-site All parts with the same thread teeth can be combined flexibly, and the ultimate goal is to use the main body of the kit to connect the two steel bar heads 6 to replace traditional welding and other processes. The combination of the main body of the kit has the following four typical connection structures:

[0025] One of the basic types:

[0026] The forward-rotating screw seat 2 and the reverse-rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com