Assembly type long-span building with combined frame structure

A frame structure, large-span technology, used in buildings, building components, building structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention will be further described below in conjunction with the accompanying drawings.

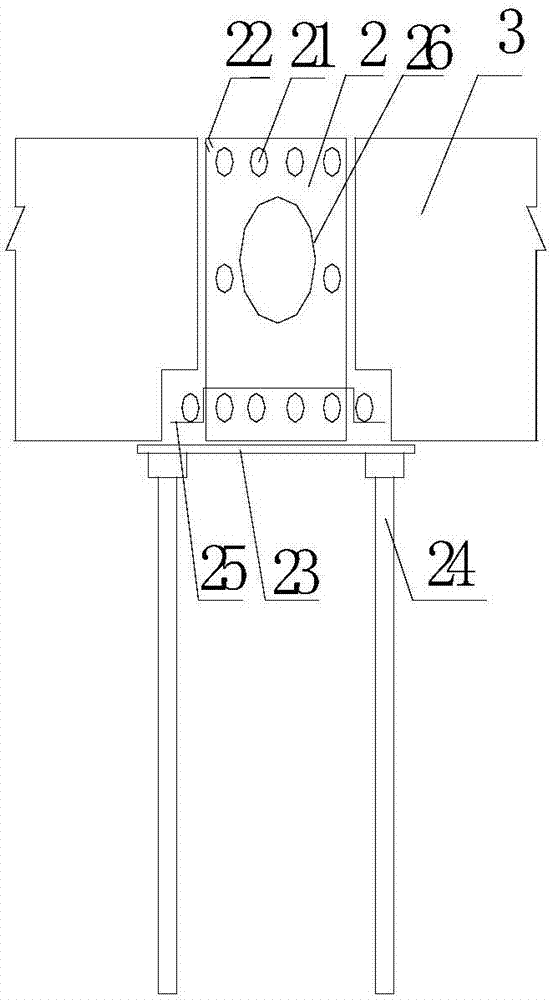

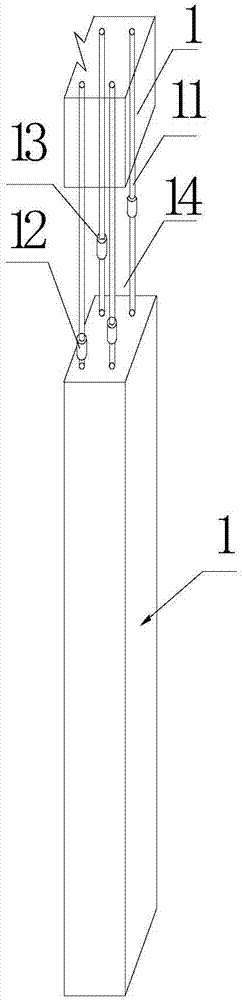

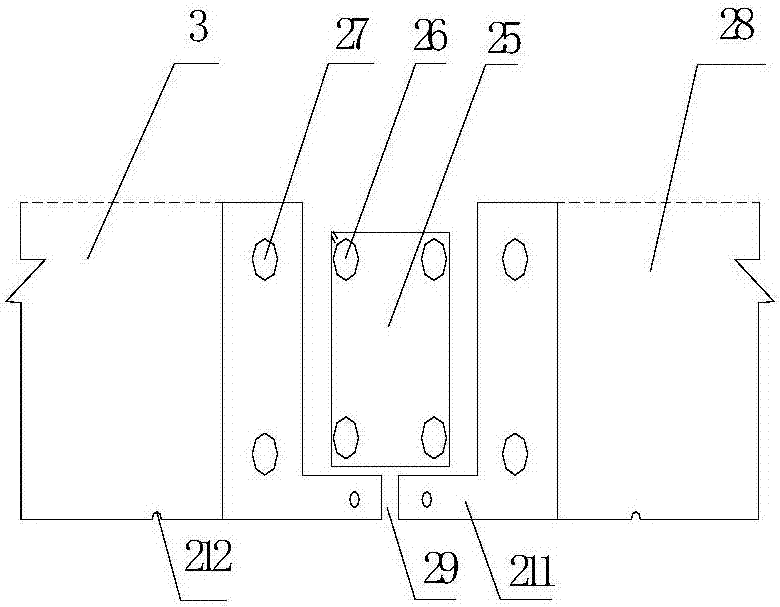

[0026] figure 1 It is an embodiment of the cross-section of the unobstructed beam floor of the prefabricated convex beam of the present invention. When the present invention is implemented, the prefabricated convex beam 2 and the bottom width of the prefabricated convex beam 2 made in the factory shall be within 600 mm, and the prefabricated convex beam 2 shall be within 600 mm. The height of 2 is within 600mm; in order to reduce the weight, a hollow beam 26 can be formed; when forming a prefabricated convex beam for a floor slab without exposed beams, the lower end of the cavity plate member is concave, and the bottom of the prefabricated convex beam 2 protrudes to a normal height It is within 100mm. At this time, ensure that the direction of the longitudinal rib beam is stressed, and the end of the steel bar at the bottom of the longitudinal rib beam is upturned by 100mm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com