A steel-concrete beam rigid-frame arch bridge

An arch bridge and steel-concrete technology, applied in the field of steel-concrete girder rigid-frame arch bridges, can solve problems such as unfavorable bridges, and achieve the effects of improving spanning capacity, increasing spanning capacity, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

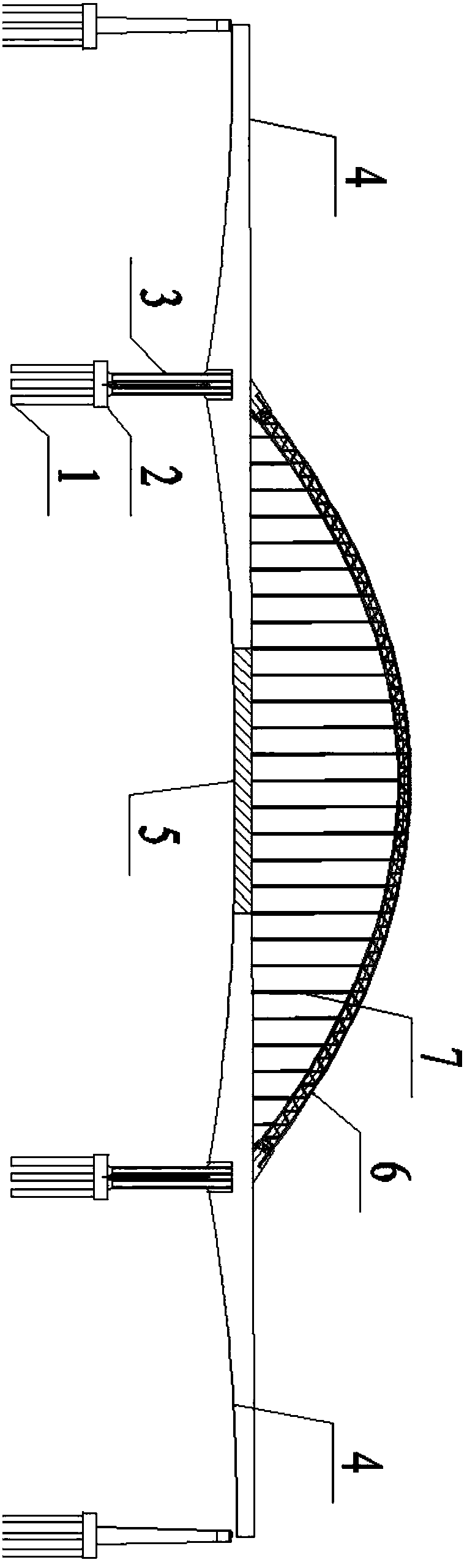

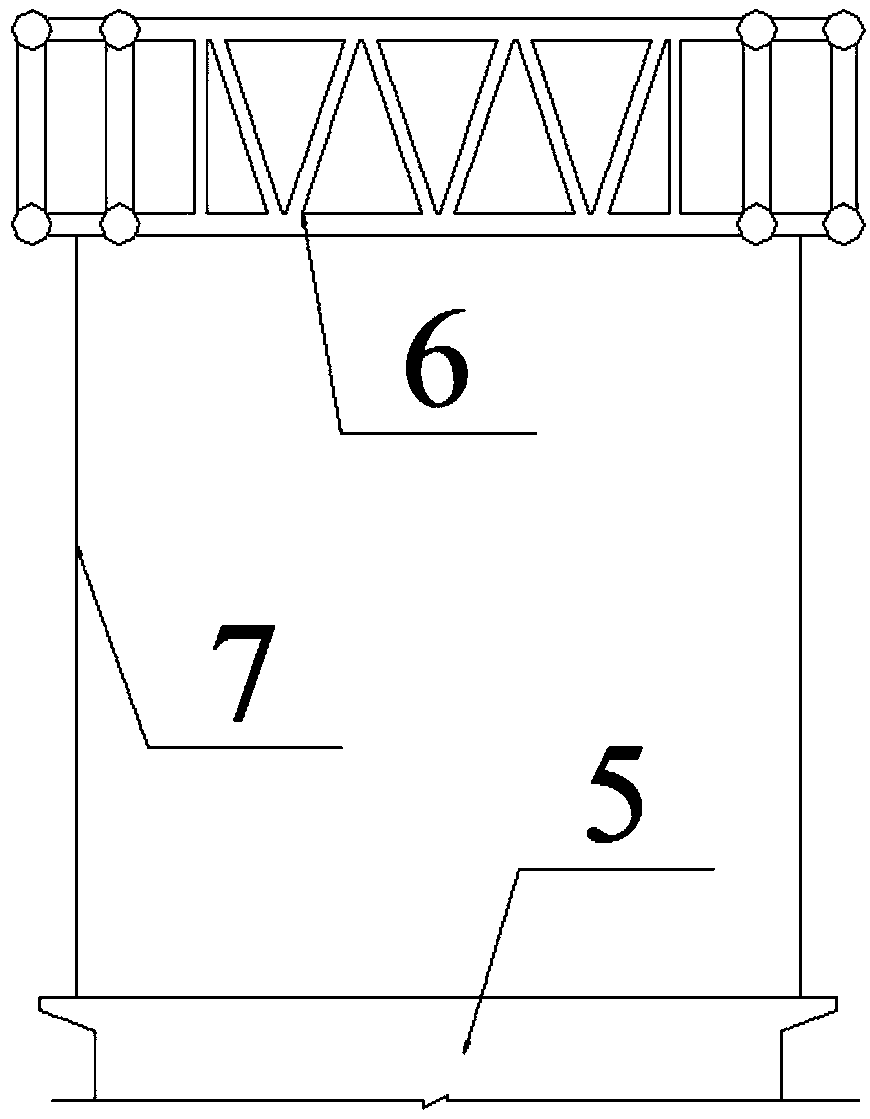

[0029] Such as Figure 1~2 , a steel-concrete beam rigid frame arch bridge, including a pile foundation 1, a cap 2 poured on the foundation 1, and a bridge pier 3 supported on the cap 2. In this embodiment, a plurality of piers 3 are provided, and the piers 3 are spaced apart along the bridge direction. Arrangement, the beam body is supported on the pier 3.

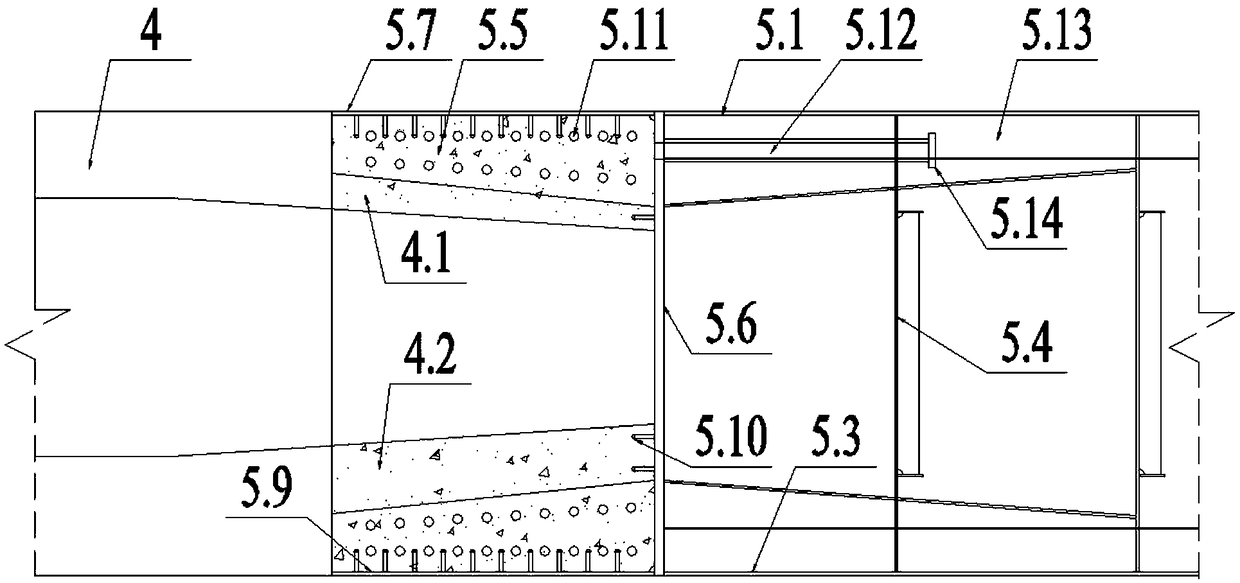

[0030] The beam body of this embodiment includes two sections of concrete beams 4 and a steel box girder 5 between the two sections of concrete beams 4, the two sections of concrete beams 4 are fixed on the upper end of the pier 3, and erected on the side span section of the bridge along the direction of the bridge And on a part of the mid-span section, a concrete beam 4 is supported by at least two bridge piers 3 , and one end of the concrete beam 4 is cantilevered and extended...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com