Anchor device for changing direction of carbon fiber plate

A carbon fiber plate and anchorage technology, applied in the field of anchorage, can solve the problems of structural adhesive aging prestress, inability to adjust, large amount of carbon fiber adhesive, etc., to achieve low friction coefficient and protection from wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

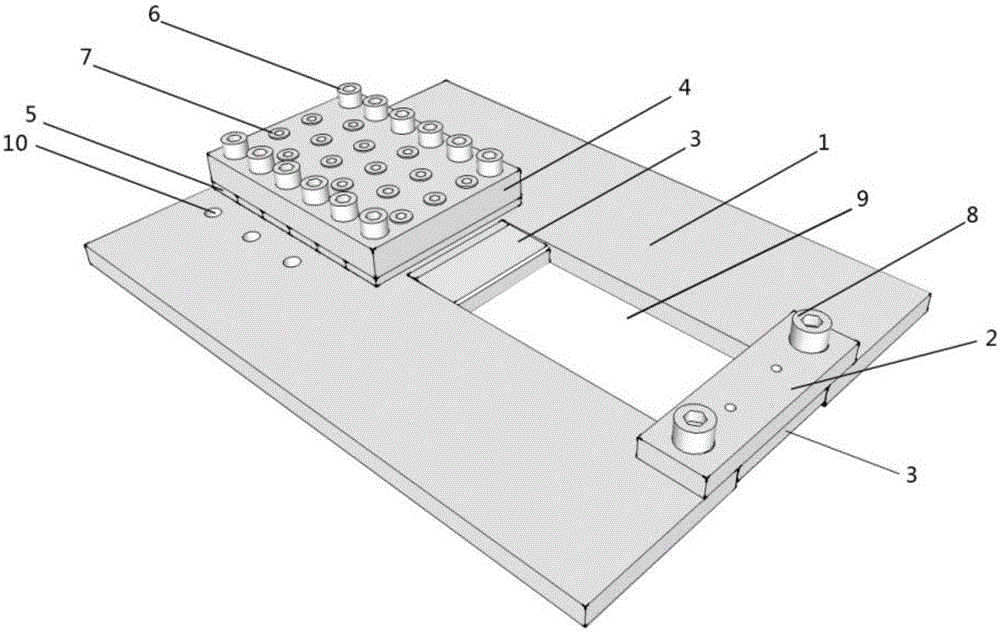

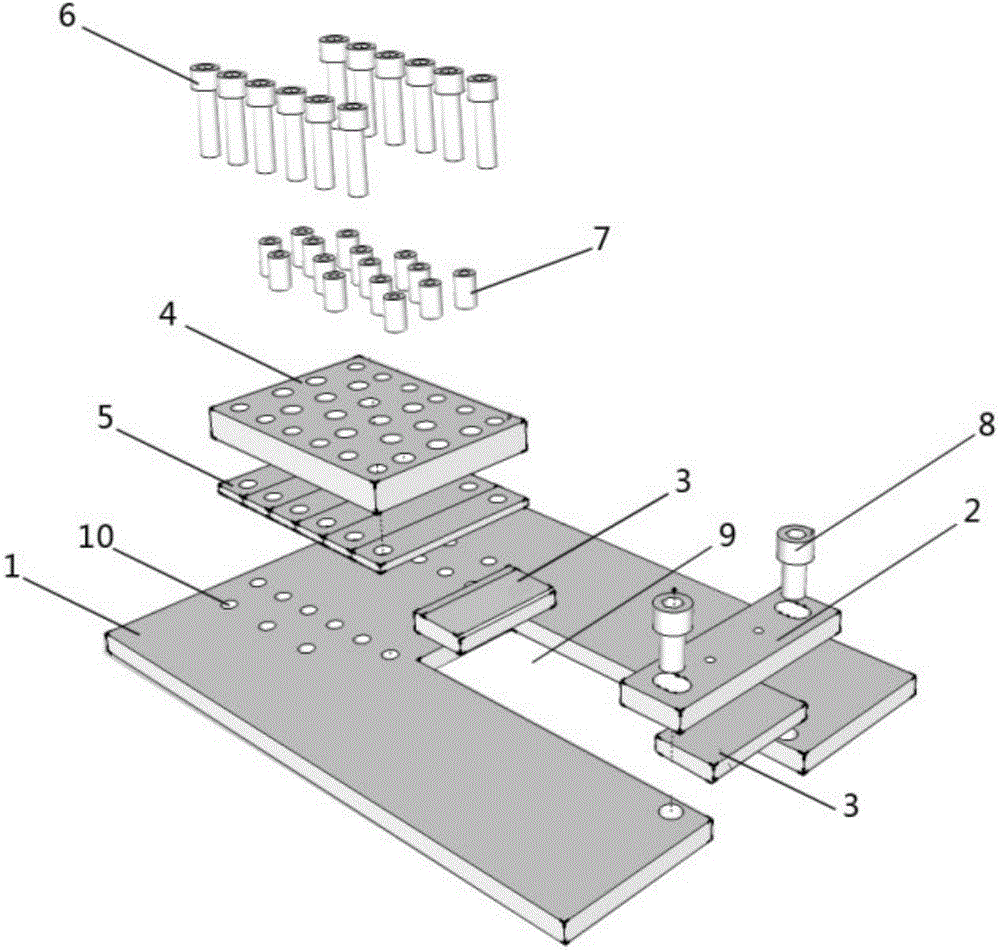

[0023] The present invention and its specific implementations will be described in further detail below in conjunction with the accompanying drawings.

[0024] see Figure 1-2 , the present invention includes a bottom plate, and it is characterized in that: one end of the bottom plate 1 is provided with an opening groove 9, and the two ends in the groove are respectively provided with steering pads 3, and above the pad at the opening end there is a screw 8 with a pressure block. Turning to the pressure block 2, the other end of the bottom plate is provided with a pressure plate 5, a cover plate 4 and a tensioning device installation hole 10, the pressure plate 5 is located between the bottom plate 1 and the cover plate 4, and the cover plate, the pressure plate and the bottom plate are connected into a whole by connecting screws 6 , The top pressure screw 7 is also provided on the cover plate 4, and the top pressure screw passes through the cover plate and is in movable crimpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com