Centralized dust removal device for cyclone dust removers and waste heat boilers

A technology of cyclone dust collector and waste heat boiler, which is applied in gas dedusting, chemical instruments and methods, liquid scrubbing gas purification, etc., can solve the problems of excessive dust in cyclone dust collector and waste heat boiler, meet environmental protection and safety requirements, reduce Pollution, the effect of solving large dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

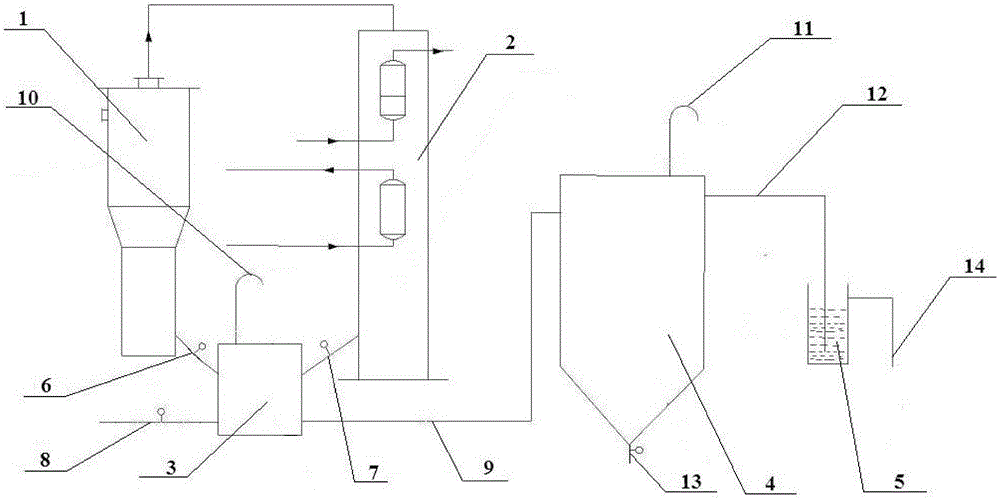

[0010] Specific Embodiment 1: In this embodiment, a device for centralized dust removal of cyclone dust collectors and waste heat boilers includes a dust collector 3, a dust collection tank 4 and a circulating water tank 5; the dust collector 3 communicates with the first discharge pipe 6 The cyclone dust collector 1 is connected, and the dust collector 3 is connected to the waste heat boiler 2 through the second discharge pipe 7. The bottom of the dust collector 3 is provided with a nitrogen pipe 8, and the dust collector 3 is connected to the waste heat boiler 2 through the delivery pipe 9. The dust collection tank 4 is connected, and the top of the dust collector 3 is provided with a first vent pipe 10; the top of the dust collection tank 4 is provided with a second vent pipe 11, and the bottom of the dust collection tank 4 is provided with The third discharge pipe 13 , the dust collecting tank 4 is connected to the circulating water tank 5 through the first overflow pipe 12...

specific Embodiment approach 2

[0013] Embodiment 2: This embodiment differs from Embodiment 1 in that: the first overflow pipe 12 is arranged on the upper part of the dust collecting tank 4 . Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com