Powder phase change energy storage material and preparation method thereof

A phase change energy storage material and energy storage material technology, applied in the field of powder phase change energy storage material and its preparation, can solve the problems of small application range, corrosion, etc., achieve excellent adsorption performance, high mechanical strength, and solve packaging problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

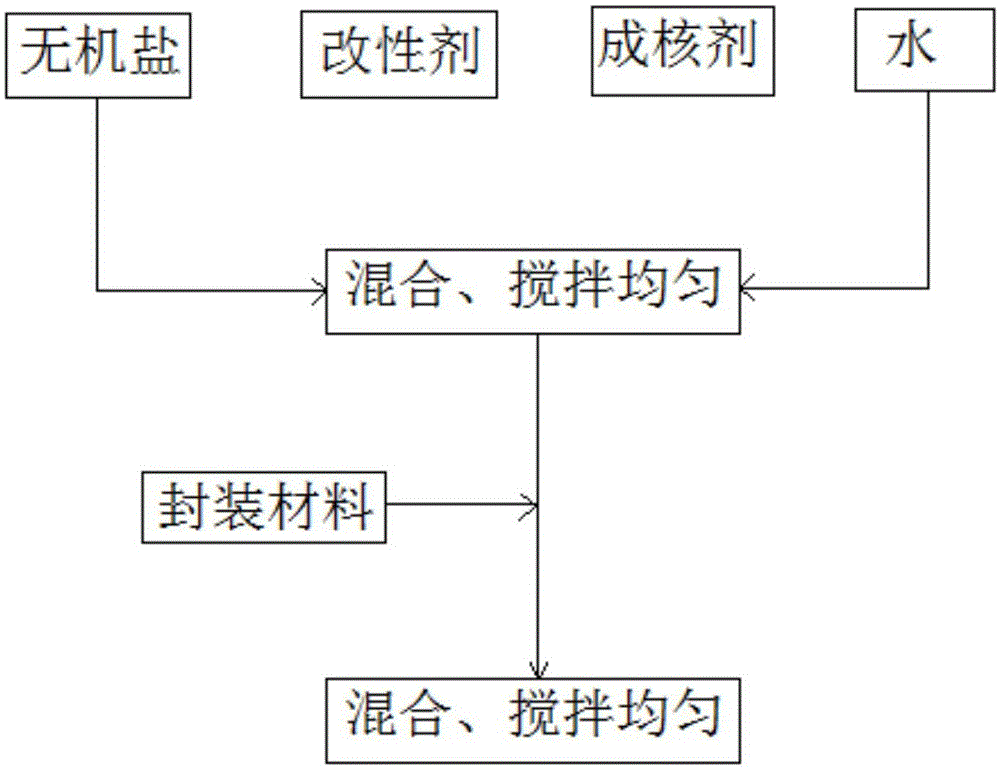

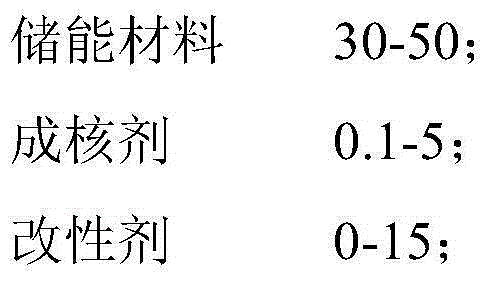

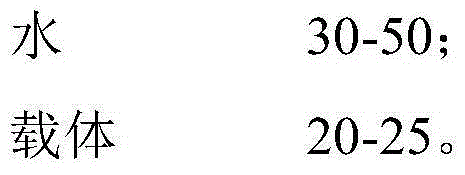

Method used

Image

Examples

Embodiment 1

[0021] Weigh 4.8kg of anhydrous calcium chloride, 0.1kg of strontium chloride, and 4.73kg of deionized water, stir evenly, add 2kg of white carbon black and stir again, put it into a ziplock bag, and bake it in an oven at 50°C for 1-2h. The powder phase change energy storage material F1 was prepared.

Embodiment 2

[0023] Weigh 4.8kg of anhydrous calcium chloride, 0.1kg of strontium chloride, and 4.73kg of deionized water, stir evenly, add 2kg of silica gel powder and stir again, put it into a ziplock bag, and bake it in an oven at 50°C for 1-2 hours to prepare The powder phase change energy storage material F2 is produced.

Embodiment 3

[0025] Weigh 4.8kg of anhydrous calcium chloride, 0.1kg of strontium chloride, 0.2kg of ammonium chloride, 4.73kg of deionized water, stir evenly, add 2kg of silica gel powder and stir again, put it into a ziplock bag, and dry it in an oven at 50°C After baking for 1-2 hours, the powder phase change energy storage material F3 is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com