Paper feeding device capable of conducting two-way paper flattening

A technology of paper and driving device, which is applied in the directions of transportation and packaging, winding strips, and thin material handling, etc., can solve the problems of non-compliant paper, paper feeding obstacles, and central protrusions, and achieve the effect of improving printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

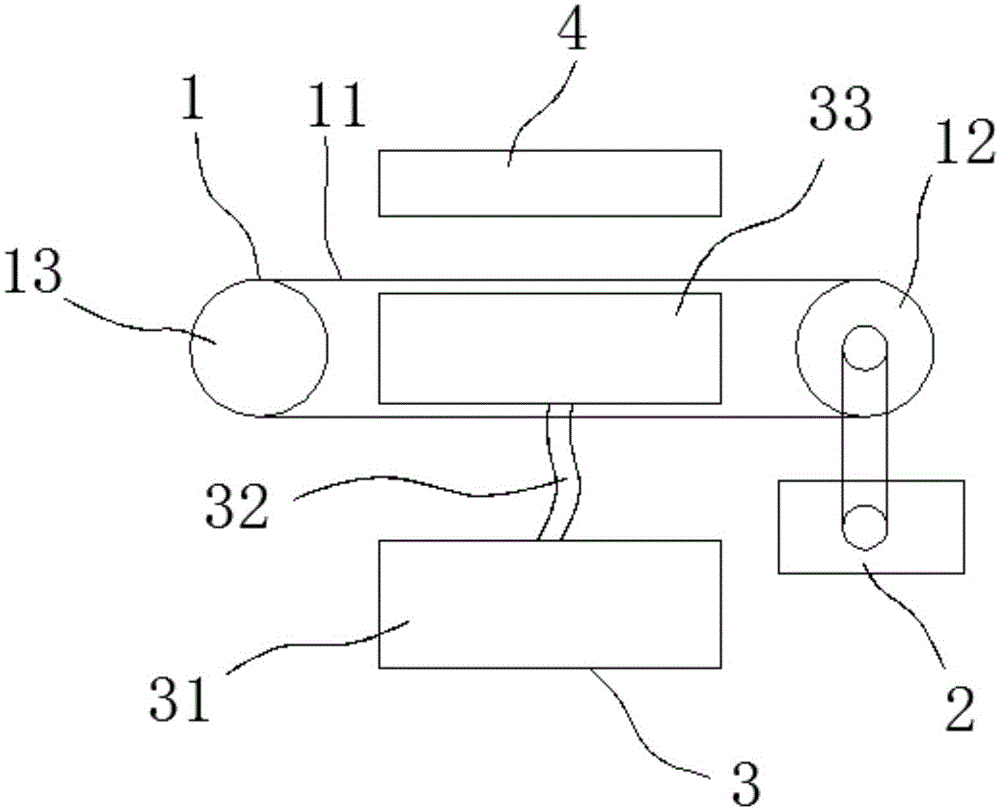

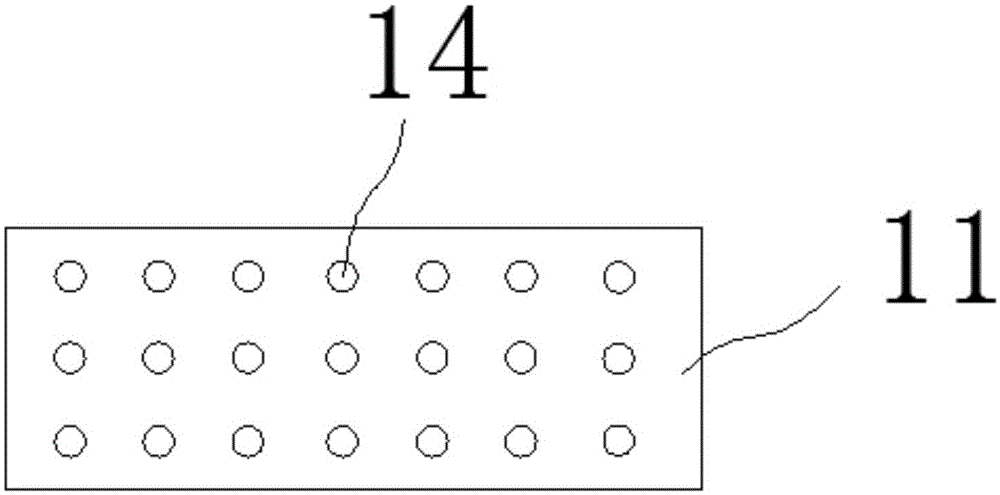

[0019] like Figure 1 to Figure 2 As shown, a paper feeding device for two-way leveling paper includes a paper transmission device 1, a driving device 2, a negative pressure device 3 and a blowing device 4, and the paper transmission device 1 includes a conveyor belt 11, a first driving wheel 12 and a second driving wheel Two drive wheels 13, the conveyor belt 11 surrounds the first drive wheel 12 and the second drive wheel 13, the first drive wheel 12 and the second drive wheel 13 drive the conveyor belt 11 to rotate, and the drive device 2 is placed On one side of the first driving wheel 12, the output shaft of the driving device 2 is linked with the first driving wheel 12; the negative pressure device 3 includes a negative pressure f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com