Orbit transferring switching mechanism

A switching mechanism and track technology, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of cumbersome maintenance and replacement, cumbersome switching mechanisms, slow movements, etc., and achieve the optimization of the layout of the welding workshop and the simple and convenient logistics , The effect of reducing the working height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

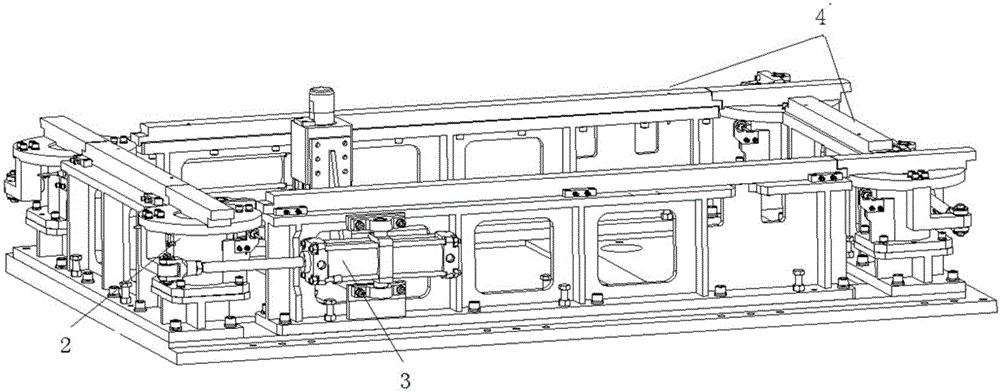

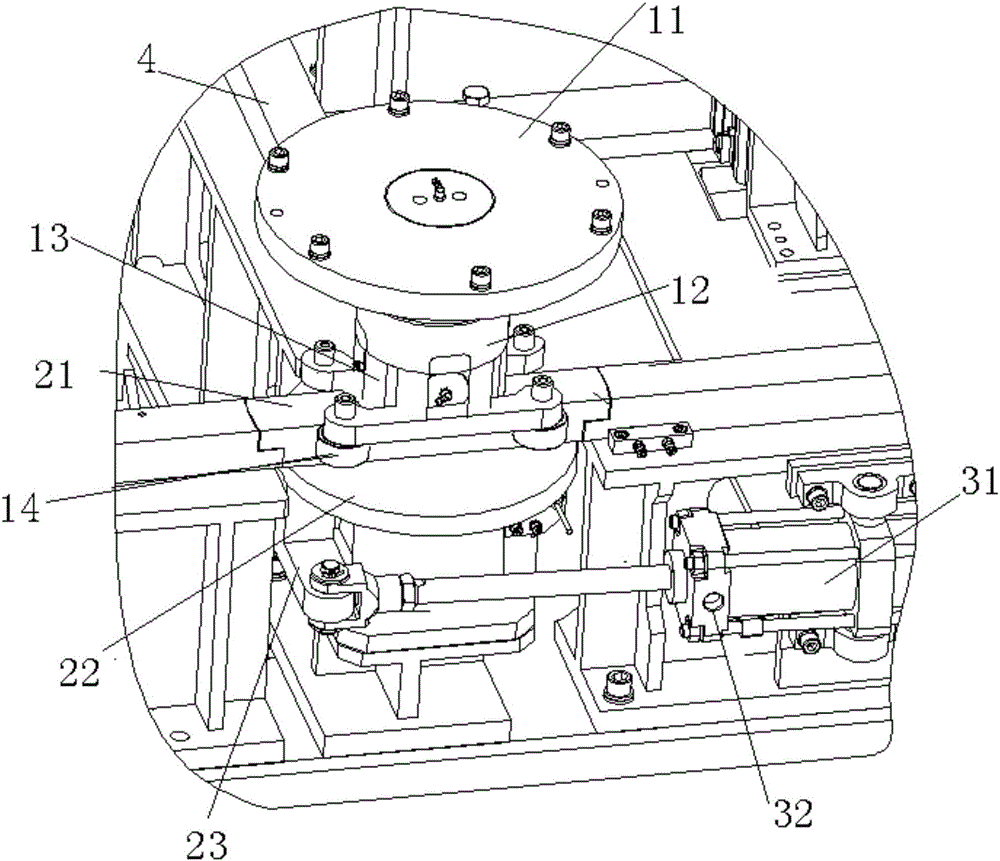

[0029] Combine figure 1 with figure 2 In this embodiment, a track change switching mechanism includes four groups of single group switching mechanisms, a fixed track group 4, and an electrical control system. The single group switching mechanism is located at the intersection of two adjacent fixed track groups 4 , The tracks of the two adjacent fixed track groups 4 are perpendicular to each other.

[0030] The single-group switching mechanism in this embodiment includes a universal support wheel group, a rotating track group 2 and a cylinder drive group 3. The universal support wheel group includes a fixed wheel 11, a connecting body 12, a universal ball 13 and a sliding wheel 14. The rotating track group 2 includes a rotating track 21, a rotating wheel 22 and a rotating side arm 23, and the cylinder driving group 3 includes a cylinder 31 and a cylinder seat 32.

[0031] The upper end of the connecting body 12 is fixedly connected to the fixed wheel 11, the lower end of the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com